Plate material applied to container and preparation method thereof

A container and plate technology, applied in chemical instruments and methods, lamination devices, manufacturing tools, etc., can solve the problems of poor compressive and flexural properties of plates, and insufficient aesthetics, so as to improve aesthetics and improve waterproof effects , the effect of high tensile strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

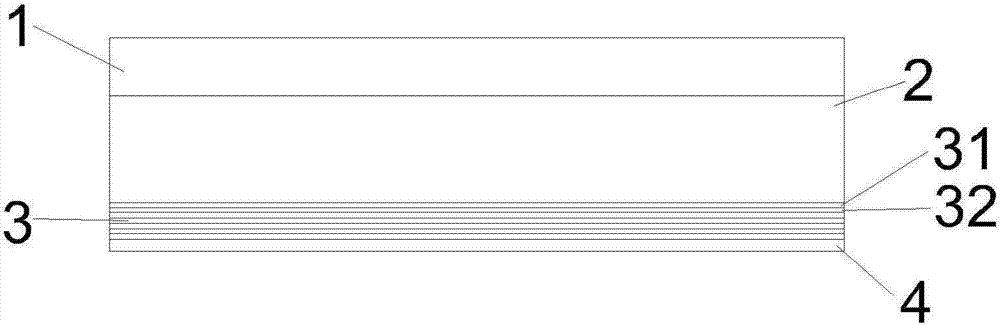

[0031] Such as figure 1 As shown, a board applied to containers includes a surface layer 1, and the surface layer 1 includes epoxy resin, curing agent, absorbent and colored sand, and the colored sand can be selected in various colors according to needs, so The surface layer 1 is sequentially connected to the middle material layer 2 and the mixed layer 3. The bottom of the mixed layer 3 is provided with a non-woven fabric layer, and the non-woven fabric layer is made of oriented or random fibers. Layer 3 includes grid cloth and glass fiber cloth. The glass fiber cloth uses alkali-free glass fiber cloth as the main material. The alkali-free glass fiber cloth is a geosynthetic material widely used in civil engineering, mainly It is composed of glass fiber and staple fiber needle-punched non-woven fabric. The mesh cloth adopts 5x5 purpose interwoven mesh cloth; the material of the middle material layer 2 is magnesium oxychloride gelling material, and the magnesium oxychloride gel...

Embodiment 2

[0039] Such as figure 1 As shown, a board applied to containers includes a surface layer 1, and the surface layer 1 includes epoxy resin, curing agent, absorbent and colored sand, and the colored sand can be selected in various colors according to needs, so The surface layer 1 is sequentially connected to the middle material layer 2 and the mixed layer 3. The bottom of the mixed layer 3 is provided with a non-woven fabric layer, and the non-woven fabric layer is made of oriented or random fibers. Layer 3 includes grid cloth and glass fiber cloth. The glass fiber cloth uses alkali-free glass fiber cloth as the main material. The alkali-free glass fiber cloth is a geosynthetic material widely used in civil engineering, mainly It is composed of glass fiber and staple fiber needle-punched non-woven fabric. The mesh cloth adopts 5x5 purpose interwoven mesh cloth; the material of the middle material layer 2 is magnesium oxychloride gelling material, and the magnesium oxychloride gel...

Embodiment 3

[0047] Such as figure 1 As shown, a board applied to containers includes a surface layer 1, and the surface layer 1 includes epoxy resin, curing agent, absorbent and colored sand, and the colored sand can be selected in various colors according to needs, so The surface layer 1 is sequentially connected to the middle material layer 2 and the mixed layer 3, and the bottom of the mixed layer 3 is provided with a non-woven fabric layer, and the non-woven fabric layer is made of oriented or random fibers;

[0048] The mixed layer 3 includes grid cloth and glass fiber cloth, and the glass fiber cloth uses alkali-free glass fiber cloth as the main material, and the alkali-free glass fiber cloth is a geosynthetic material widely used in civil engineering , which is mainly composed of glass fiber and staple fiber needle-punched non-woven fabric, and the mesh cloth adopts 5x5 purpose interwoven mesh cloth;

[0049] The material of the middle material layer 2 is magnesium oxychloride ce...

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com