Preparation method of polybutyrate adipate terephthalate (PBAT) composite material

A technology of butylene terephthalate and polybutylene terephthalate, which is applied in the field of modification of biodegradable polymer materials polybutylene adipate-terephthalate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

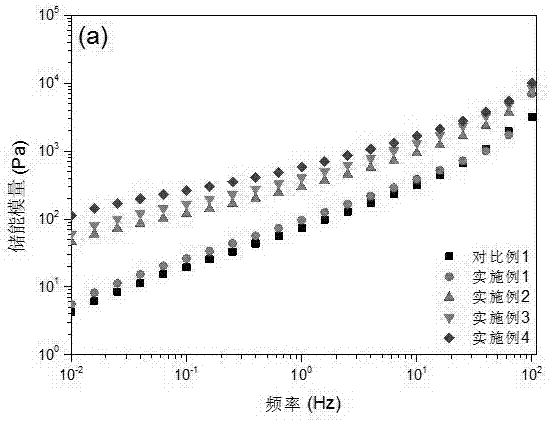

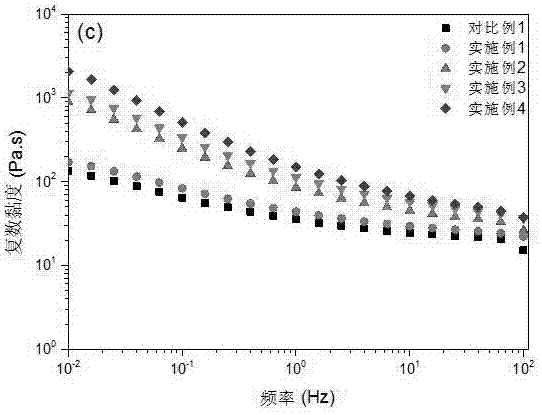

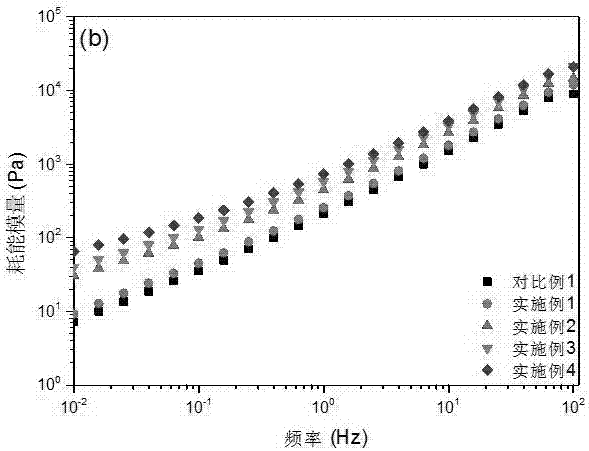

Examples

Embodiment 1

[0025] 1. will PBAT Dry in an oven at 60°C for 24 h to remove moisture.

[0026] According to the dosage ratio of 1g: 2.5ml, the dried PBAT and chloroform into the beaker, and magnetic stirring, until PBAT After complete dissolution, add aNCC Mix thoroughly (wherein, aNCC and PBAT According to the mass ratio of 1:100), a premix is made.

[0027] The obtained premix is uniformly coated, vacuum-dried to remove chloroform, and placed in a twin-screw extruder for melt blending. Control the temperature of the extruder at 130-140°C, the screw speed at 50rpm, and melt blend for 3 minutes. , that is, get PBAT / aNCC composite material.

[0028] 2. Using a hydraulic molding machine, the blend was molded at 130°C and 10 MPa for 3 minutes, and then cold-pressed at room temperature for 5 minutes to make a 1 mm thick sheet for testing.

Embodiment 2

[0030] 1. will PBAT Dry in an oven at 60°C for 20 h to remove moisture.

[0031] According to the dosage ratio of 1g: 2ml, the dried PBAT and chloroform into the beaker, and magnetic stirring, until PBAT After complete dissolution, add aNCC Mix thoroughly (wherein, aNCC and PBAT According to the mass ratio of 3:100), a premix is made.

[0032] The obtained premix is uniformly coated, dried in vacuum to remove chloroform, placed in a twin-screw extruder for melt blending, the temperature of the extruder is controlled at 140°C, the screw speed is 80rpm, and after melt blending for 3 minutes, the get PBAT / aNCC composite material.

[0033] 2. Using a hydraulic molding machine, the blend was molded at 130°C and 10 MPa for 5 minutes, and then cold-pressed at room temperature for 5 minutes to make a 1 mm thick sheet for testing.

Embodiment 3

[0035] 1. will PBAT Dry in an oven at 60°C for 20 h to remove moisture.

[0036] According to the dosage ratio of 1g: 3ml, the dried PBAT and chloroform into the beaker, and magnetic stirring, until PBAT After complete dissolution, add aNCC Mix thoroughly (wherein, aNCC and PBAT According to the mass ratio of 5:100), a premix is made.

[0037] The obtained premix is evenly coated with a film, vacuum dried to remove chloroform, placed in a twin-screw extruder for melt blending, the temperature of the extruder is controlled at 130° C., the screw speed is 50 rpm, and after melt blending for 3 minutes, the get PBAT / aNCC composite material.

[0038] 2. Using a hydraulic molding machine, the blend was molded at 130°C and 10 MPa for 5 minutes, and then cold-pressed at room temperature for 5 minutes to make a 1 mm thick sheet for testing.

PUM

| Property | Measurement | Unit |

|---|---|---|

| melting point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com