Decorative coating prepared on aluminum substrate based on magnetron common sputtering technology

An aluminum substrate, decorative technology, applied in the direction of metal material coating process, coating, sputtering plating, etc., can solve problems such as covering, and achieve the effect of preventing electrochemical corrosion

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

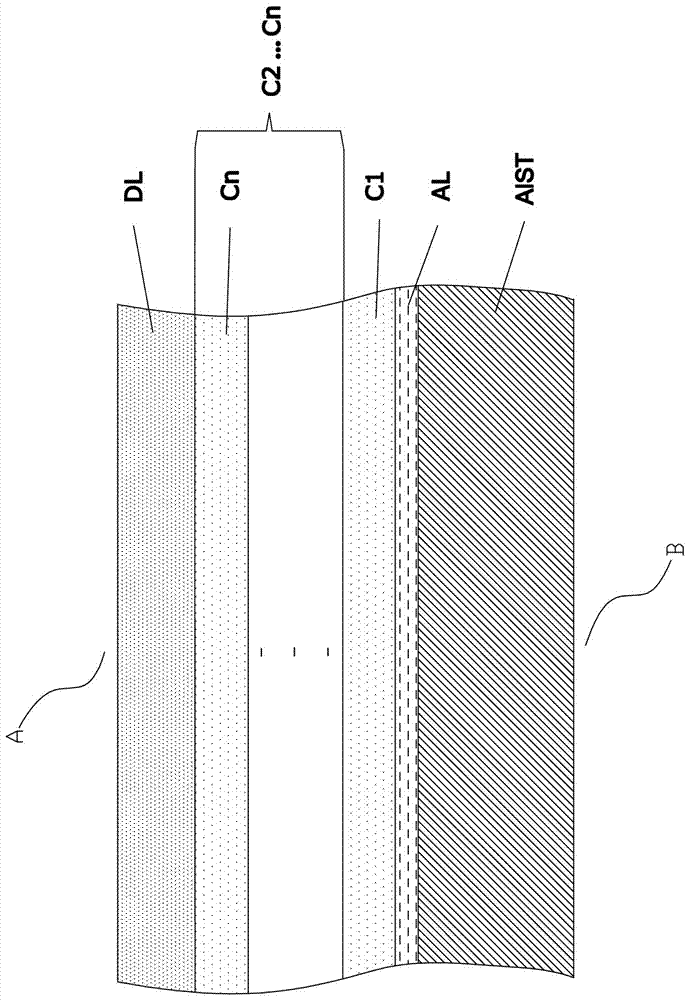

[0024] Refer to the attached figure 1 Specific embodiments of the present invention will be described. In order to provide a comprehensive understanding of the present invention, many details are described below, but it will be apparent to those skilled in the art that the present invention can be practiced without these details.

[0025] A decorative coating prepared on an aluminum substrate based on magnetron co-sputtering technology. The coating film system includes an aluminum substrate material in the form of a strip or sheet, the back of which is B, and the coating surface is A. If only one side of the aluminum base material has a surface treatment suitable for the intended PVD coating, then the side with the appropriate surface treatment is the coating side A; if both sides of the aluminum base material are similar or both sides are suitable for the intended PVD coating , then the coating surface A can be randomly selected.

[0026] An adhesion layer (AL) composed of ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com