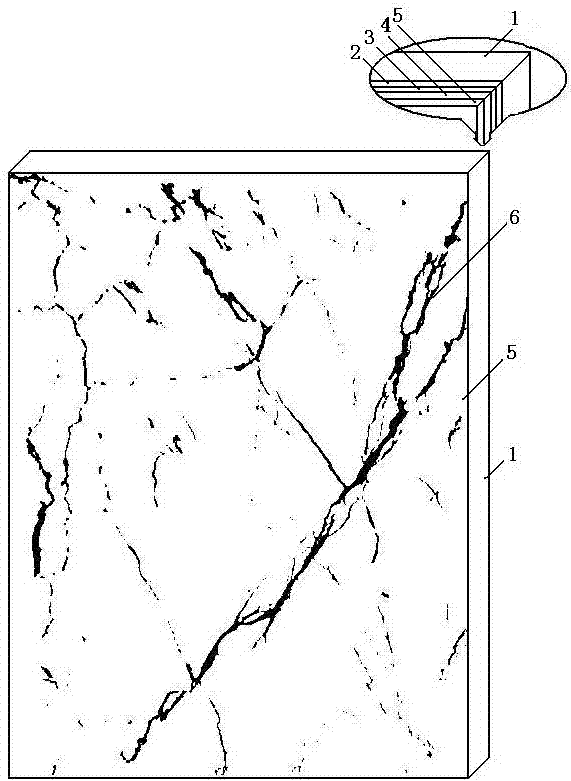

Structure and preparation technology of stripped glaze ornamental brick

A preparation process and a technology of removing glaze, which is applied to clay products, building structures, applications, etc., to meet market demand and protect the ecological environment.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0062] Embodiment 1: The green body layer raw material structure includes:

[0063] Underwear white clay 6%

[0064] Zhangzhou White Clay 7%

[0065] Zhangputu No. 1 5%

[0066] Washed Kaolin 11%

[0067] Talc 6%

[0068] Washed sand 7%

[0069] Longshan Albite 4%

[0070] Longshan Albite 6%

[0071] Changtai Kaolin 3%

[0072] Longhai feldspar 14%

[0073] Daping stone rice 16%

[0074] Bentonite 10%

[0075] Zhangputu No. 2 5%.

Embodiment 2

[0076] Embodiment 2: the glaze raw material structure of glaze layer comprises:

[0077] TORRECID—CNK00348 87%

[0078] Alumina 6%

[0080] Sodium carboxymethyl cellulose 0.4%

[0081] Sodium Tripolyphosphate 0.6%.

Embodiment 3

[0082] Embodiment 3: The raw material preparation process steps of the green body layer include:

[0083] Step 1: Accurately measure by electronic measuring instruments according to the composition ratio of raw material structure;

[0084] Step 2: Put the measured raw materials into the ball mill, add water according to the ratio of raw materials / water=60T / 22T, and grind for 13 hours to form raw material slurry;

[0085] Step 3: The raw material slurry is discharged into the No. 1 mud pool through the 80-mesh screen from the ball mill;

[0086] Step 4: The raw material mud entering the No. 1 mud pool is left to stand for 48 hours for the first aging;

[0087] Step 5: Transport the stale raw material slurry to the No. 2 slurry pool through an 80-mesh screen and a strong magnetic iron remover;

[0088] Step 6: The raw material slurry after iron removal is left to stand for 24 hours in the No. 2 mud pool for the second aging;

[0089] Step 7: Spray the stale mud for the second...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com