Cylinder sleeve for oil exploitation and preparation method of cylinder sleeve

A technology for oil extraction and cylinder liner, applied in the direction of cylinders, mechanical equipment, components of pumping devices for elastic fluids, etc., can solve the problems of wear resistance, corrosion resistance and fatigue resistance characteristics Potential safety hazards, insufficient uniformity of cylinder liner texture, etc., to achieve the effect of improving mechanical performance, ensuring safety, and enhancing strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

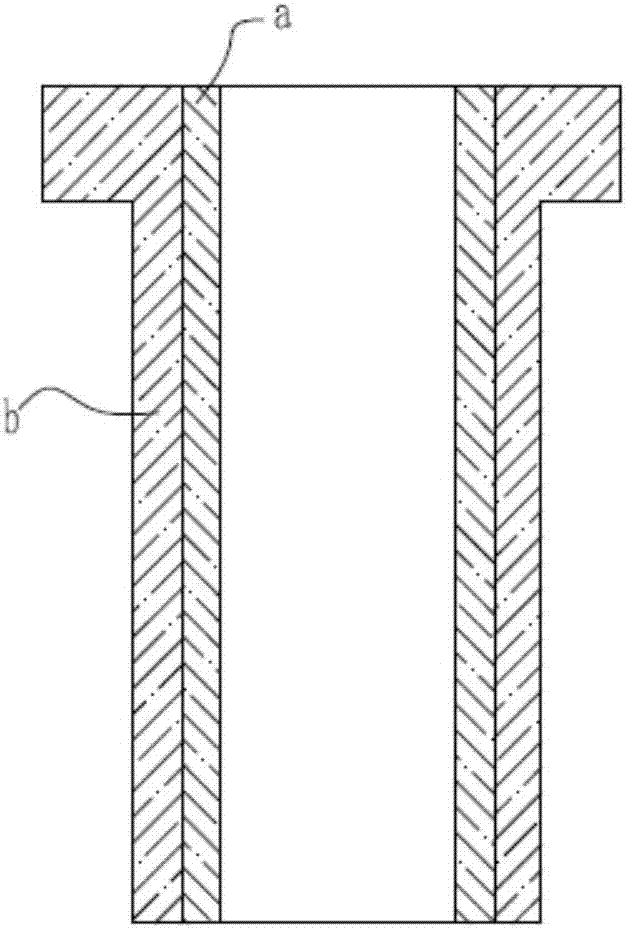

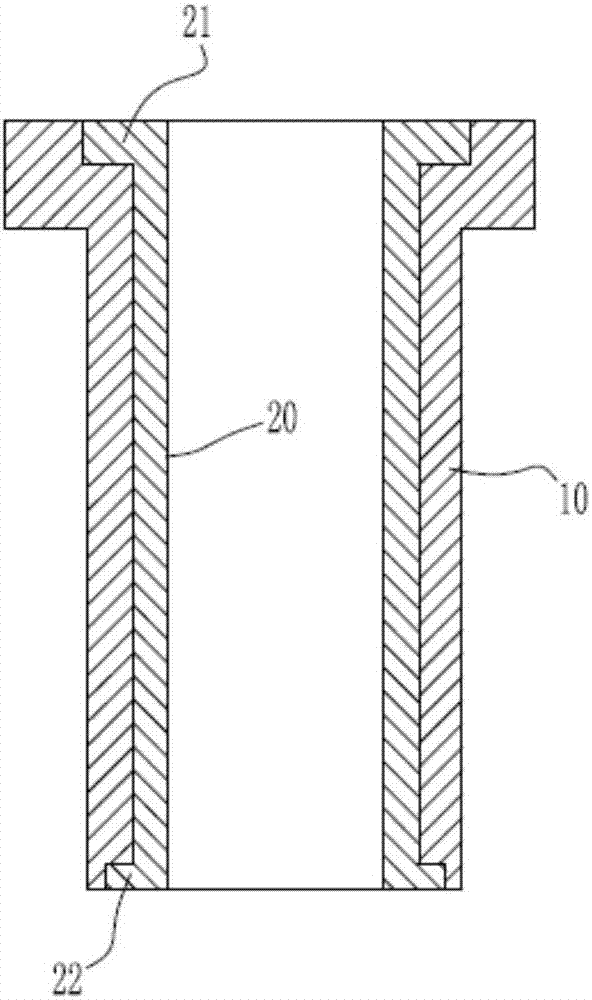

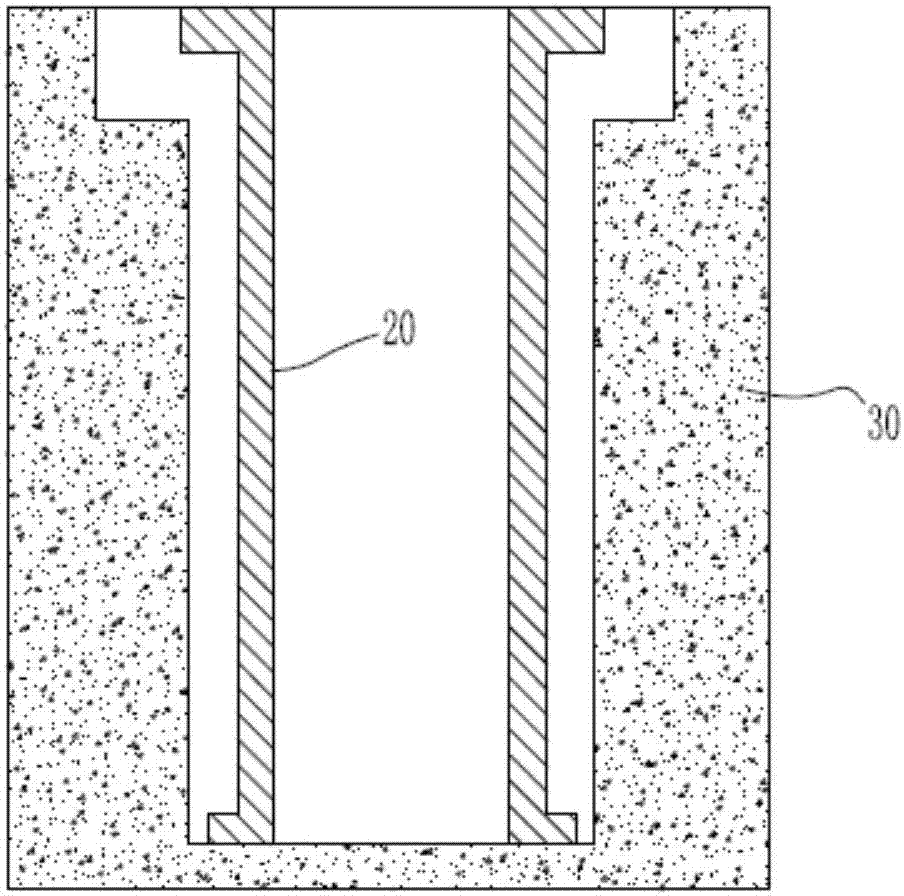

[0043] Such as Figure 2-4As shown, a cylinder liner for oil development includes an outer sleeve 10 and an inner sleeve 20; the inner sleeve 20 is embedded in the outer sleeve 10; the two ends of the inner sleeve 20 are respectively provided with a first ring sleeve 21 and a second The two rings 22, the first ring 21 and the second ring 22 are integrally formed with the inner sleeve 20; the two ends of the outer sleeve 10 are respectively provided with a first ring groove and a second ring groove. The first ring sleeve 21 is located in the first ring groove, and the second ring sleeve 22 is located in the second ring groove.

[0044] By setting the first ring sleeve 21 and the second ring sleeve 22 on the inner sleeve 20, the outer sleeve 10 is provided with a first ring groove and a second ring groove respectively matched with the first ring sleeve 21 and the second ring sleeve 22, Clamping the inner sleeve 21 in the outer sleeve 10 completely avoids the risk of the traditi...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com