Line structured light visual sensor calibration method based on sawtooth target

A technology of visual sensor and calibration method, which is applied in the field of sensor calibration, and can solve the problems of unable to capture target feature point images, difficult to clear images, difficult to capture clear feature point and light bar image information, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

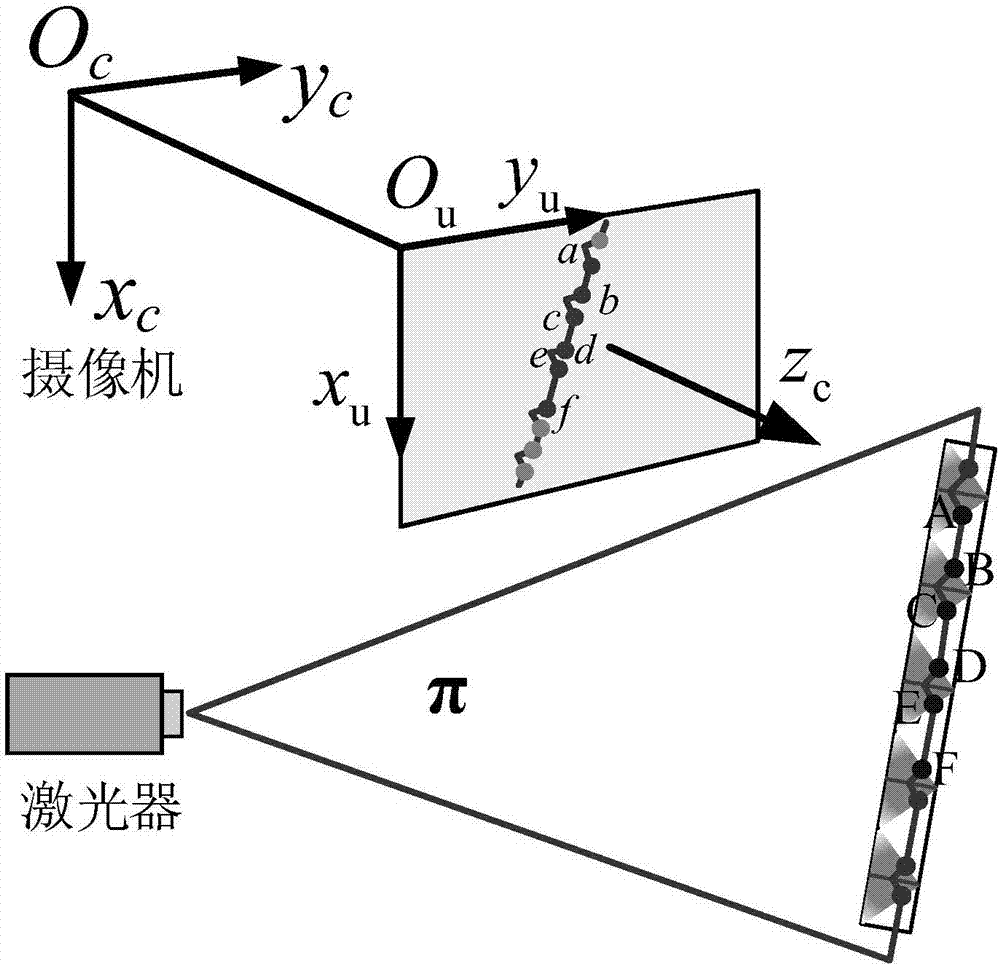

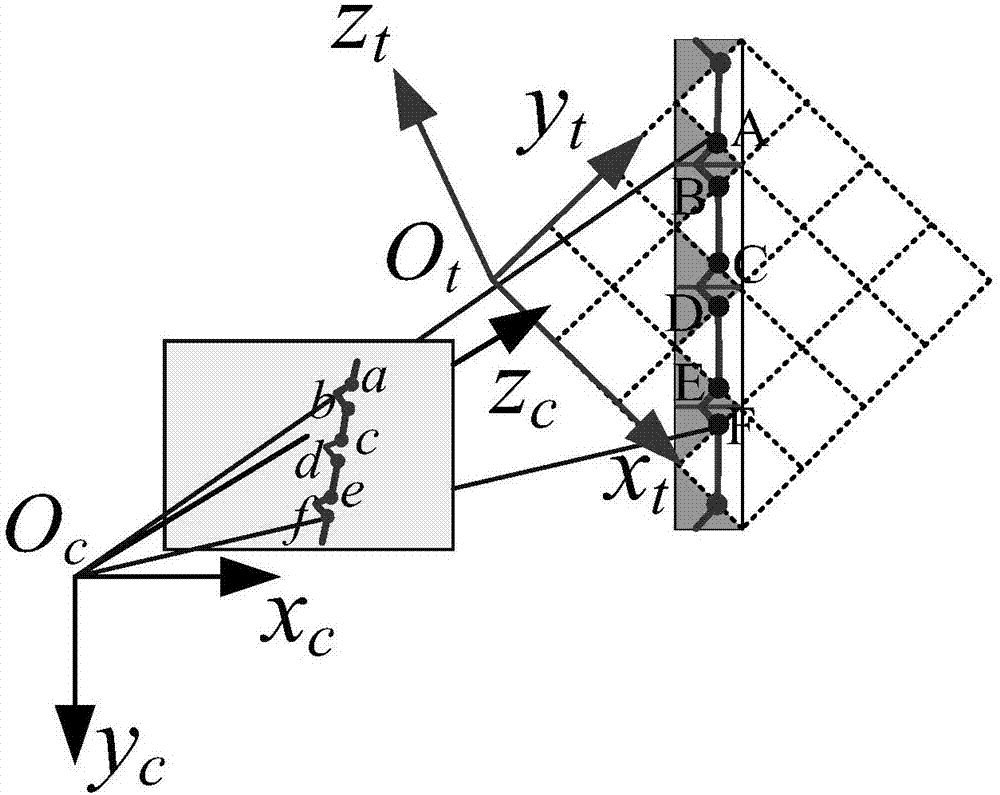

[0027] The basic idea of the present invention is: based on the constant cross-ratio, solve the initial solution of the three-dimensional coordinates of the intersection point of the light strip and the jagged edge of the target, that is, the feature point in the camera coordinate system, and add the filter model, and solve the light plane equation through optimization, that is, realize Calibration of line structured light vision sensors.

[0028] Hereinafter, the present invention will be further described in detail by taking a line structured light vision sensor composed of a camera and a line laser as an example.

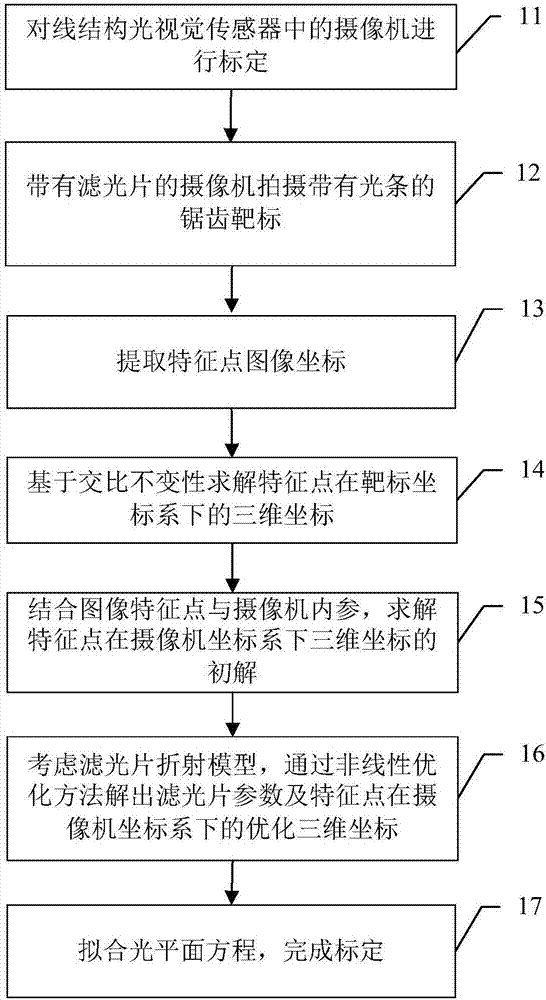

[0029] Such as figure 1 As shown, the calibration method of the line structured light vision sensor based on the sawtooth target of the present invention mainly includes the following steps:

[0030] Step 11: Calibrate the camera in the line structured light vision sensor without a filter.

[0031] Here, the calibration of the camera of the visual sensor is t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com