Device and method for testing ash accumulation characteristics of flue gas waste heat exchanger

A flue gas waste heat and heat exchanger technology, which is applied in the field of industrial waste heat recovery, can solve the problems of inconvenient disassembly and assembly and replacement of heat exchange tubes, and achieves the effect of reliable test results and overcoming human error.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

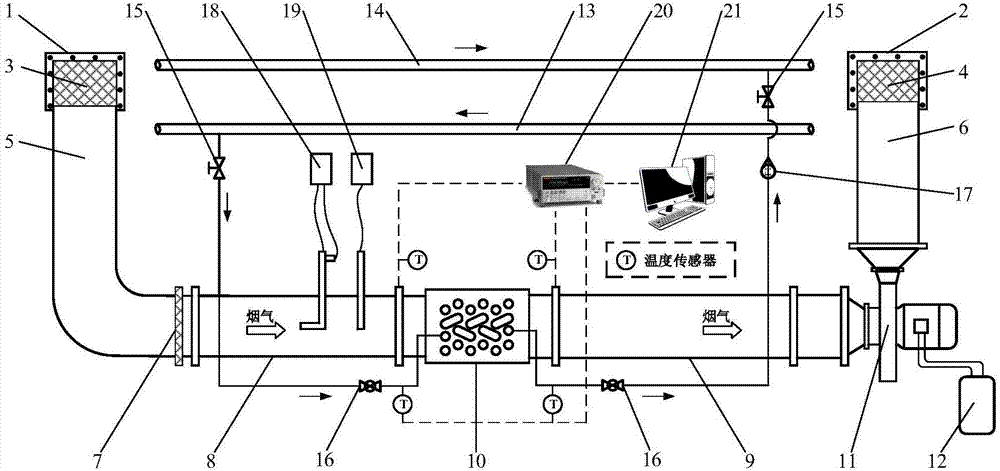

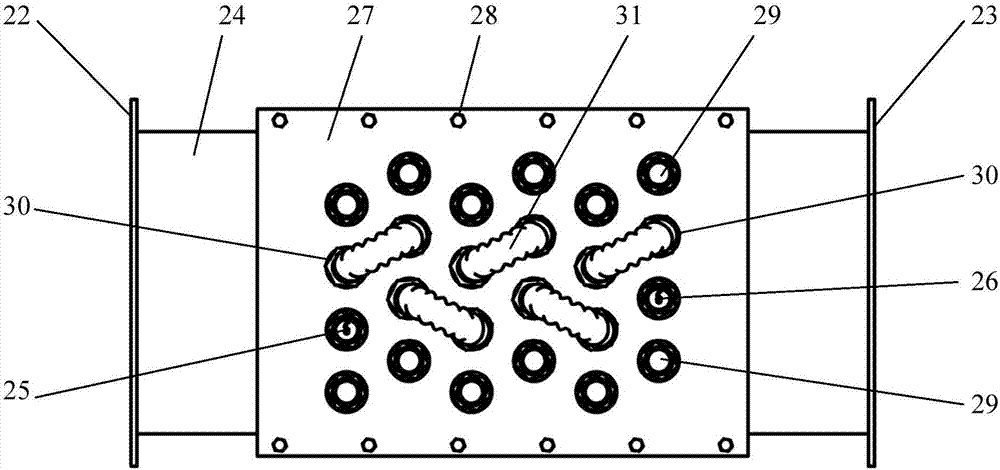

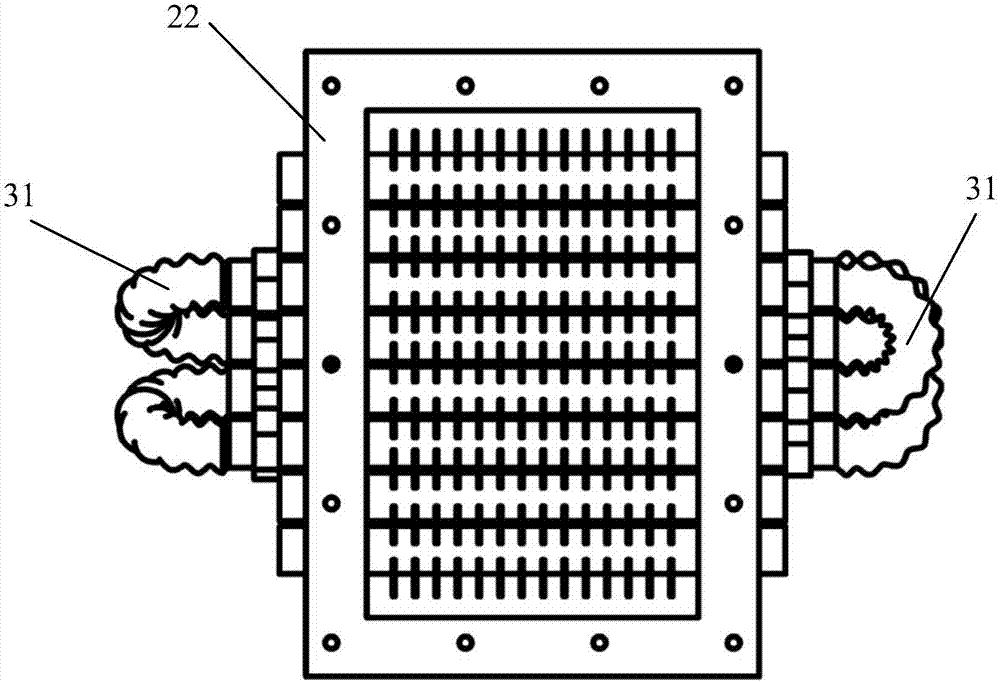

[0032] The specific implementation manners of the present invention will be described in detail below in conjunction with the drawings and embodiments.

[0033] The present invention mainly utilizes the characteristic that the heat transfer coefficient will decrease when the surface of the heat exchange tubes accumulates dust, and calculates the heat transfer in real time by monitoring the flue gas temperature at the inlet and outlet of the heat exchanger in the test section and the water temperature at the inlet and outlet in real time. The decreasing trend and amount of the heat transfer coefficient of the heat exchanger over time are calculated to calculate the fouling thermal resistance of the heat exchanger, and then to evaluate the ash deposition characteristics of the heat exchange tube. The device of the present invention can be installed on the front side of the dust collector of the utility boiler or the heating boiler. In this example, the device system of the prese...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com