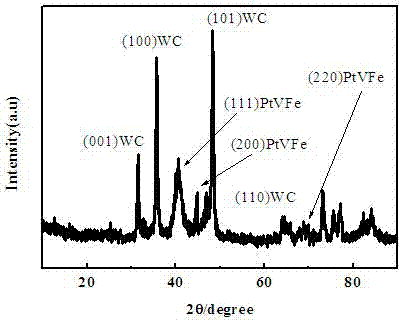

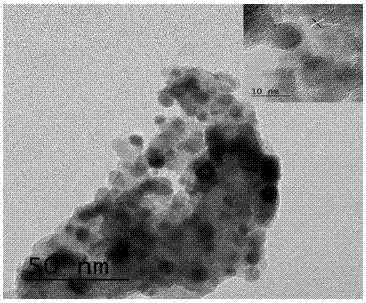

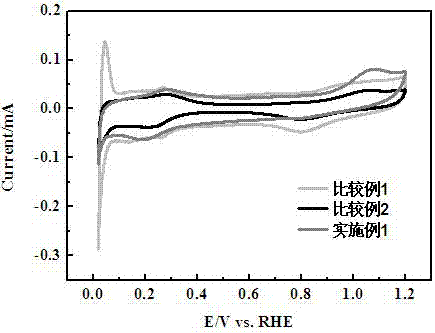

Preparation method of PtVFe/WC/C nano-oxygen reduction catalyst

A catalyst and nano-composite technology, applied in electrical components, battery electrodes, circuits, etc., can solve the problems of catalyst cathode power limitation, achieve high catalytic activity and stability, prolong cycle life, and improve oxygen reduction efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0028] The preparation method of the PtVFe / WC / C oxygen reduction catalyst of embodiment 1, comprises the following steps:

[0029] 1) Add 140 mg of tungsten carbide and carbon powder mixture into 200 mL of hexane, sonicate for 2 hours, and then add 60 mg of the prepared PtVFe solution (platinum source, vanadium source, iron source is platinum acetylacetonate, vanadium acetylacetonate, five Carbonyl iron) to prepare PtVFe / WC / C mixed solution;

[0030] 2) The mixed solution was sonicated for 1 hour, and then stirred for 16 hours;

[0031] 3) in nitrogen (N 2 ) under the protection of stirring for 4-8 hours, the suspension slowly evaporated;

[0032] 4) Put the evaporated product in N 2 Collect and dry under protection to obtain PtVFe / WC / C powder;

[0033] 5) Put PtVFe / WC / C powder in N 2 Heat treatment under protection for 60 min at 260°C;

[0034] 6) Heat-treated PtVFe / WC / C powder in 15% H 2 +85%N 2 The PtVFe / WC / C nanocomposite oxygen reduction catalyst was obtained by ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| The average particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com