Graphene/MoS2 heterojunction modified graphite felt electrode material and application thereof

An electrode material and heterojunction technology, which is applied in the direction of material analysis, material analysis, and material electrochemical variables through electromagnetic means, can solve the problems of low catalytic efficiency and achieve good catalytic selectivity, improved electrical conductivity, and electronic conduction. high efficiency effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

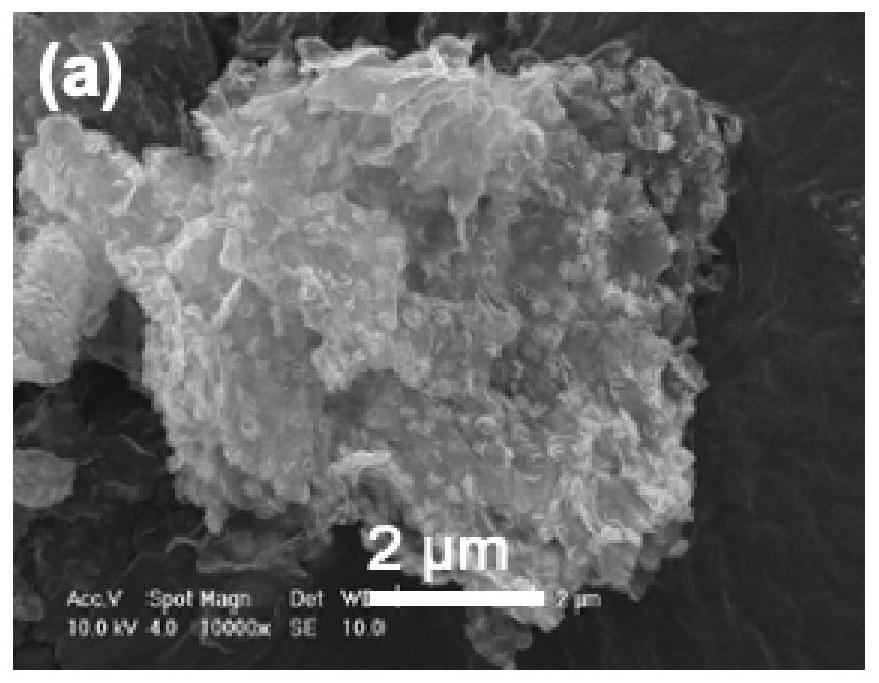

[0053] Graphene / MoS of the present embodiment 2 The preparation method of the graphite felt electrode material modified by heterojunction, the preparation steps are as follows:

[0054] (1) Will (NH 4 ) 6 Mo 7 o 24 4H 2 O and thiourea (CS(NH 2 ) 2 ) successively dissolves in appropriate amount of water, then adds graphene oxide aqueous solution in above-mentioned aqueous solution, obtains mixed solution after mixing; Ammonium paramolybdate molar concentration is 5 * 10 in the mixed solution -3mol L -1 , the molar ratio of thiourea / ammonium paramolybdate was 30:1, and the concentration of graphene oxide was 0.8 mg·mL -1 , transfer the mixed solution into a closed reaction vessel, and place the closed reaction vessel in an oven or muffle furnace for hydrothermal synthesis reaction. The hydrothermal reaction temperature is 220°C, and the reaction time is 24 h. After the reaction, dry to obtain nano heterojunction precursors;

[0055] (2) Anneal the precursor obtained in...

Embodiment 2

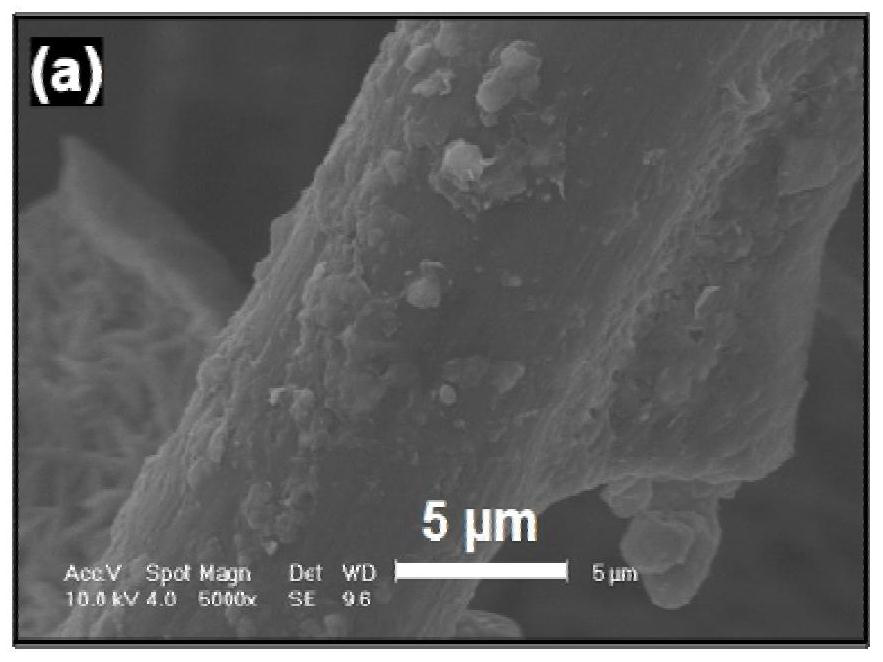

[0064] Graphene / MoS of the present embodiment 2 The preparation method of the graphite felt electrode modified by heterojunction, the preparation steps are as follows:

[0065] (1) Will (NH 4 ) 6 Mo 7 o 24 4H 2 O and thiourea (CS(NH 2 ) 2 ) successively dissolved in appropriate amount of water, then add graphene oxide aqueous solution in above-mentioned aqueous solution, obtain mixed solution after mixing evenly; Ammonium molybdate molar concentration is 4 * 10 in the mixed solution -3 mol L -1 , the molar ratio of thiourea / ammonium molybdate was 29:1, and the concentration of graphene oxide was 0.7 mg·mL -1 , transfer the mixed solution to a closed reaction vessel, and place the closed reaction vessel in an oven or muffle furnace for hydrothermal synthesis reaction. The hydrothermal reaction temperature is 200°C, the reaction time is 20 h, and the reaction is dried to obtain nano heterojunction precursors;

[0066] (2) Anneal the precursor obtained in step (1) in a...

Embodiment 3

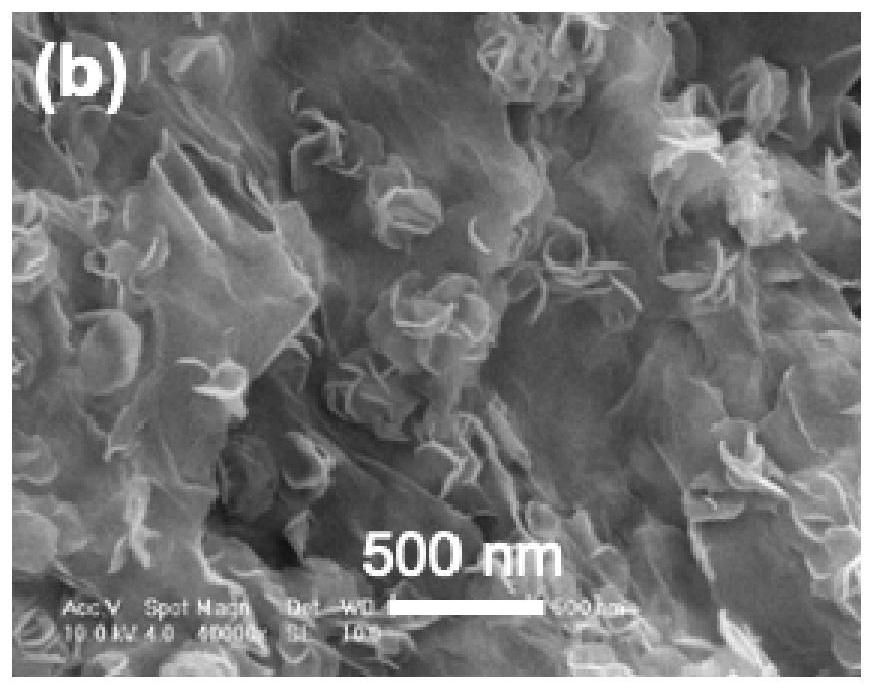

[0070] Graphene / MoS of the present embodiment 2 The preparation method of the graphite felt electrode modified by heterojunction, the preparation steps are as follows:

[0071] (1) ammonium paramolybdate ((NH 4 ) 6 Mo 7 o 24 4H 2 O) and thiourea (CS(NH 2 ) 2 ) were successively dissolved in deionized water, and then an aqueous solution of graphene oxide was added to the aqueous solution, and mixed evenly to obtain a mixed solution. The range of molar concentration of ammonium paramolybdate in the mixed solution is 6×10 -3 mol L -1 , the molar ratio of thiourea / ammonium paramolybdate is 40:1, and the concentration range of graphene oxide is 0.9 mg·mL -1 .

[0072] Transfer the mixed solution to an airtight reaction vessel, and place the airtight reaction vessel in an oven or muffle furnace for hydrothermal synthesis reaction. The hydrothermal reaction temperature is 250°C, and the reaction time is 50h. After the reaction, filter, wash and dry Obtain nano-heterojuncti...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thermal conductivity | aaaaa | aaaaa |

| Density | aaaaa | aaaaa |

| Specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com