Tubular positive plate and preparation method thereof

A positive plate and tubular technology, applied in the field of tubular positive plate and its preparation, can solve the problems affecting battery charge and discharge performance, low porosity of tubular positive plate, uneven current potential, etc., to improve electron transmission speed and The effect of electrochemical reaction area, small electron transport resistance, and consistent crystal form

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

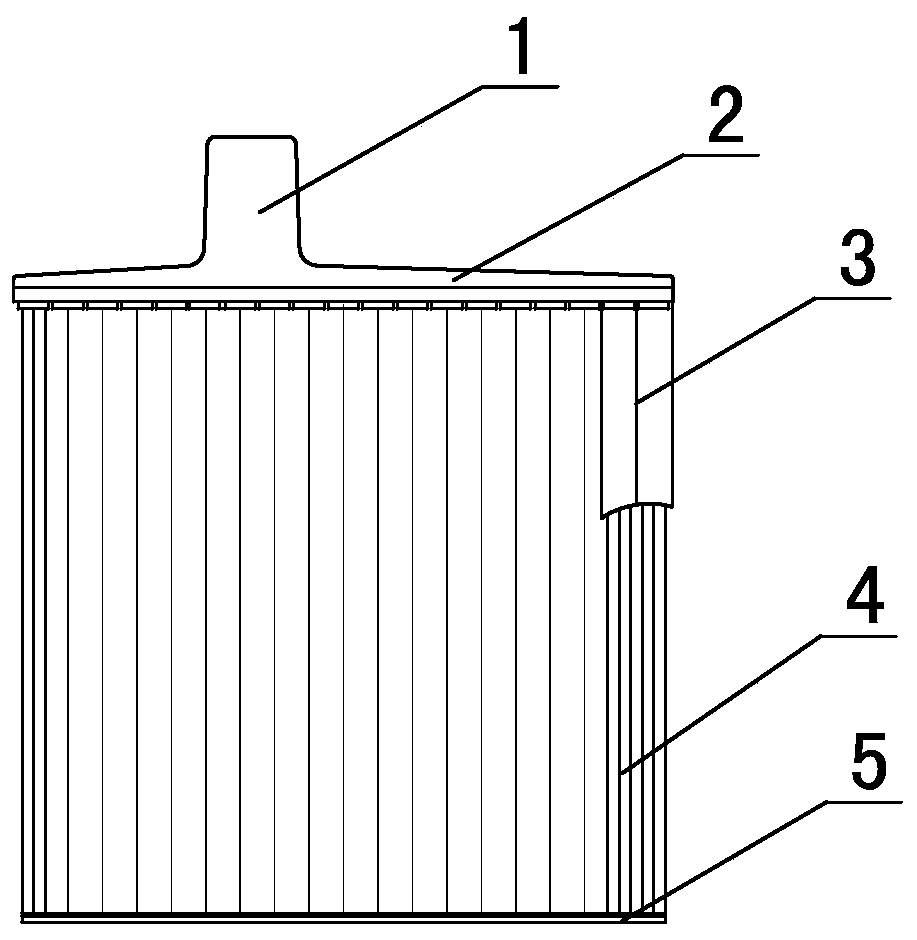

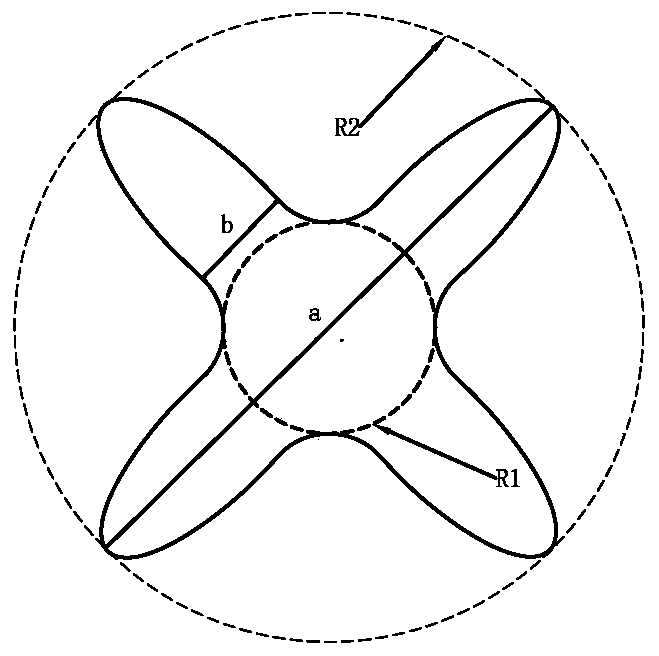

[0028] After heating the lead-antimony quinary alloy to 325±25°C, cold-extrude to form clover leaf-shaped ribs 4 (leaves are 4 pieces), and after making 14 ribs 4 into a length of 115mm, cast and weld to form the upper beam 2 And plate lug 1 (plate lug 1 is trapezoidal, vertical angle is 2°), the upper beam 2 is a positive grid with a width of 145mm, and then the non-woven fabric pipe 3 is set. After the lead powder is poured, use conductive plastic containing carbon fiber The bottom is sealed, and then enters the pickling and curing procedures. Use 3 pieces of the positive plate and 4 pieces of the traditional negative (side) plate of the lead-acid battery to assemble a 2V 60Ah simulated battery. The results are shown in Table 1.

[0029] Table 1

[0030]

[0031]

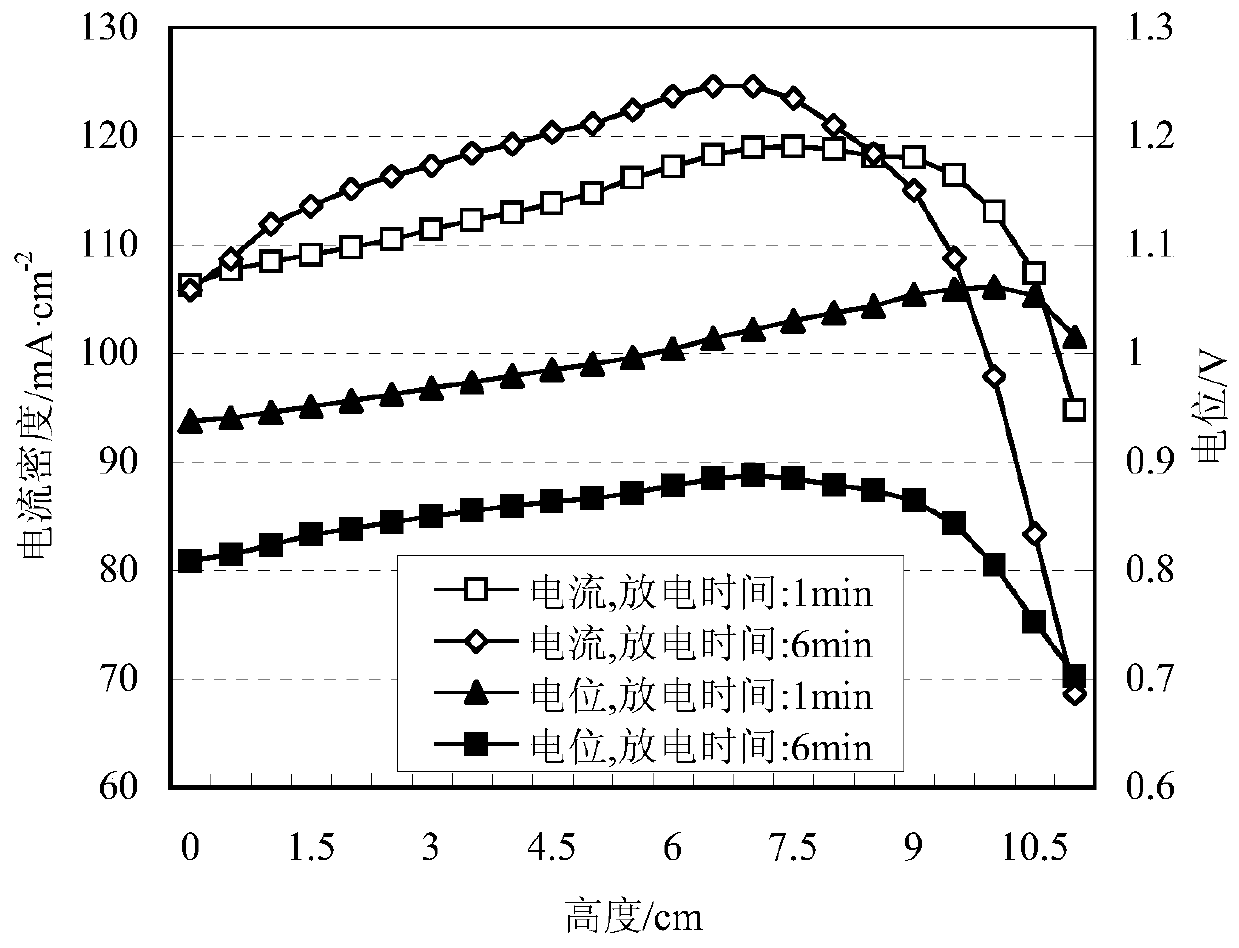

[0032] Detect the potential distribution of the monolithic electrode during the discharge of 3C current, see the results image 3 . It can be seen from the figure that although the positive plate is disch...

Embodiment 2

[0034] After heating the lead-antimony quinary alloy to 325±25°C, cold-extrude to form cloverleaf-shaped ribs 4 (leaves are 2 pieces), and after making 14 ribs 4 into 310mm in length, casting and welding form the upper beam 2 And the plate lug 1 (the plate lug 1 is trapezoidal, the vertical angle is 4°), the upper beam 2 is a 145mm wide 2DB120H lead-acid battery positive grid for tractors, and then the non-woven fabric pipe 3 is installed, and after the lead powder is poured, Use conductive plastic with Teflon and conductive carbon black to seal the bottom, then enter the pickling and curing procedures, use 2 pieces of the positive plate and 3 pieces of the traditional negative (side) plate of the lead-acid battery to assemble a 2V120Ah sample battery , the initial performance test was carried out after the acid cycle was formed, and the test results are shown in Table 2.

[0035] Table 2

[0036] project GB / T 7403.1-2008 standard requirements Test data Fir...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com