Negative electrode material and preparation method thereof, negative electrode plate and secondary battery

A negative electrode material and nanosphere technology, which is applied in the direction of secondary batteries, negative electrodes, battery electrodes, etc., can solve the problems of large volume expansion and poor conductivity of negative electrode materials, so as to improve cycle life, avoid failure, and reduce electron transmission resistance. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0038] A preparation method of negative electrode material, comprising the following steps:

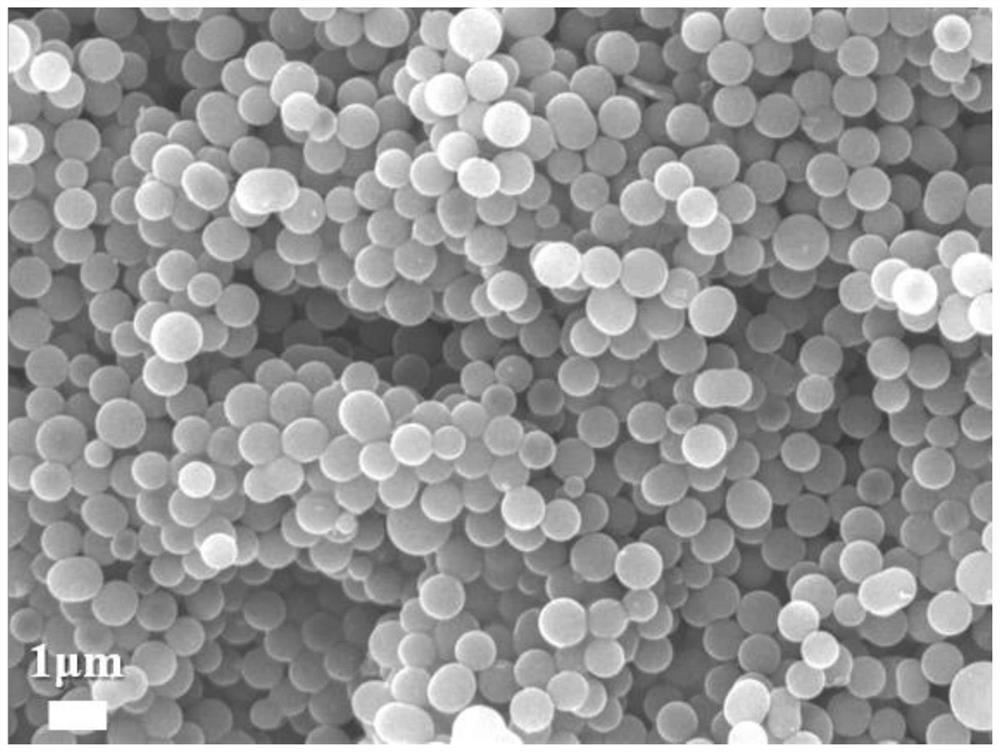

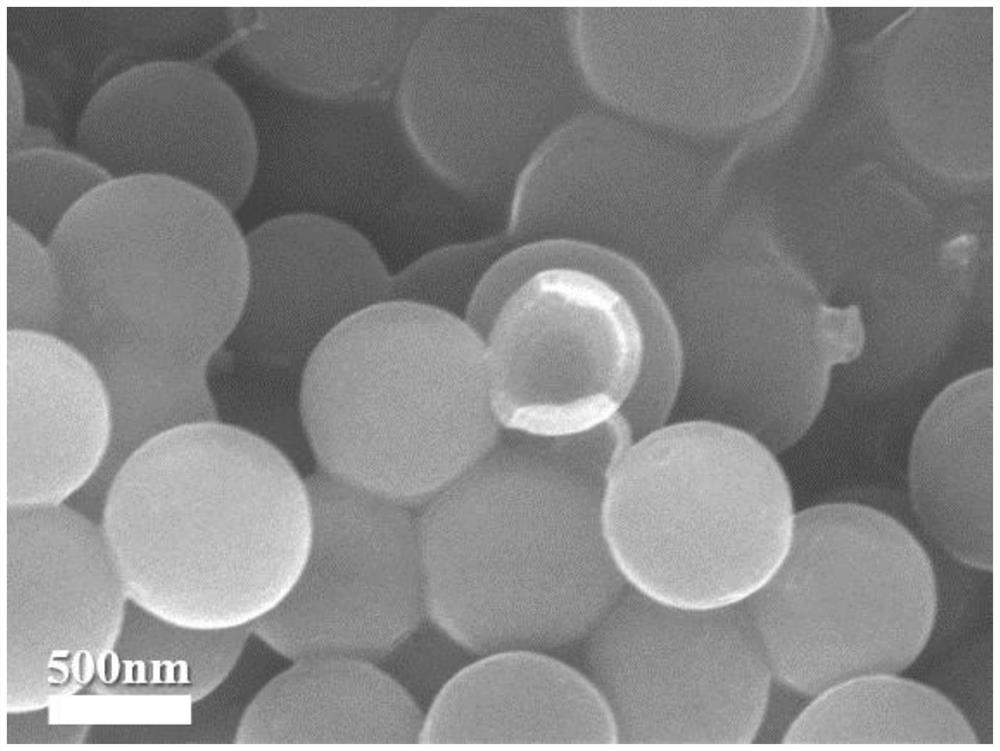

[0039] Step S1. Dissolve 15g of glucose and 1g of cetyltrimethylammonium bromide (CTAB) in 5ml of pure water with stirring, transfer to a hydrothermal reactor, heat to 180°C for 12 hours, and wait for it to cool to room temperature Remove the coke layer between the solution and the air, collect the product by centrifugation, and wash repeatedly with pure water and ethanol until the washing solution is white and transparent, and finally dry to obtain carbon nanospheres, as figure 1 shown.

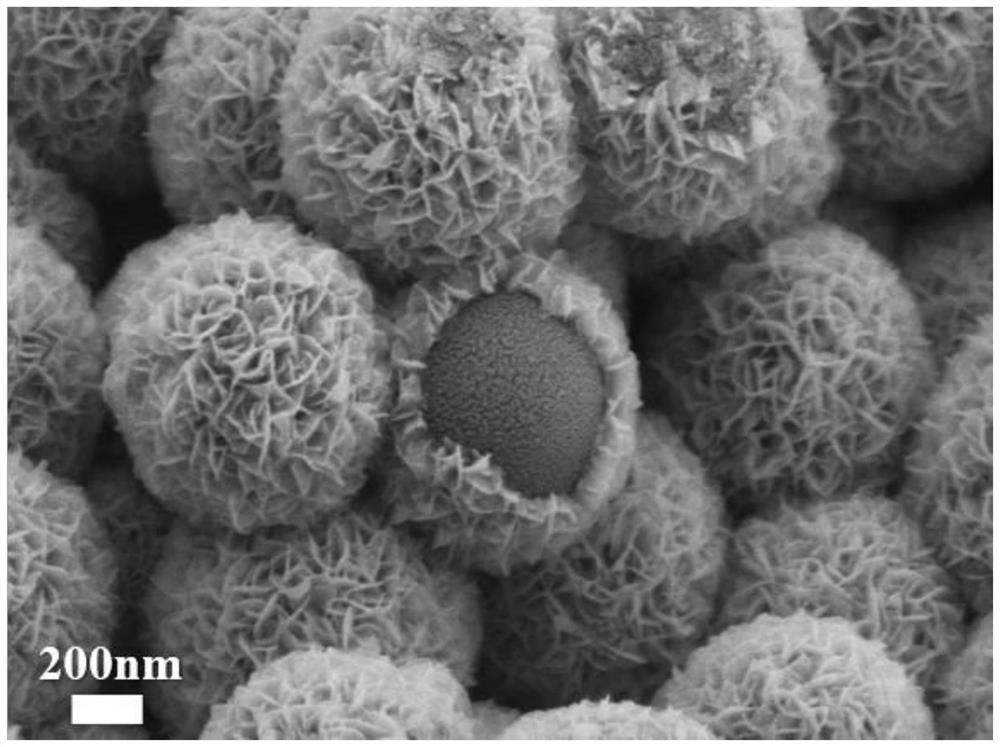

[0040] Step S2, stirring and dissolving one or more metal chlorides in a solvent, the solvent is a solution of water and ethanol in a volume ratio of 1:2 (the ratio is not lower than 1:1), and the solid is completely dissolved Afterwards, the carbon nanosphere template was added, placed in an environment of 40°C and stirred for 12 hours, and then centrifuged and washed to collect the product to obt...

Embodiment 2

[0044] The difference from Example 1 is that the weight-to-number ratio of hollow nanospheres, ammonium perrhenate, hydroxylamine hydrochloride and thiourea in step S4 is 6:0.4:2.1:1.3.

[0045] The rest are the same as in Embodiment 1, and will not be repeated here.

Embodiment 3

[0047] The difference from Example 1 is that the weight-to-number ratio of hollow nanospheres, ammonium perrhenate, hydroxylamine hydrochloride and thiourea in step S4 is 5:0.4:2.1:1.3.

[0048] The rest are the same as in Embodiment 1, and will not be repeated here.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com