Method for producing flame-resistant, non-corrosive and stable polyamide moulding compounds

A non-corrosive, polymer technology, applied in the direction of chemical change-inhibiting compositions, chemical instruments and methods, etc., which can solve unavoidable problems

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

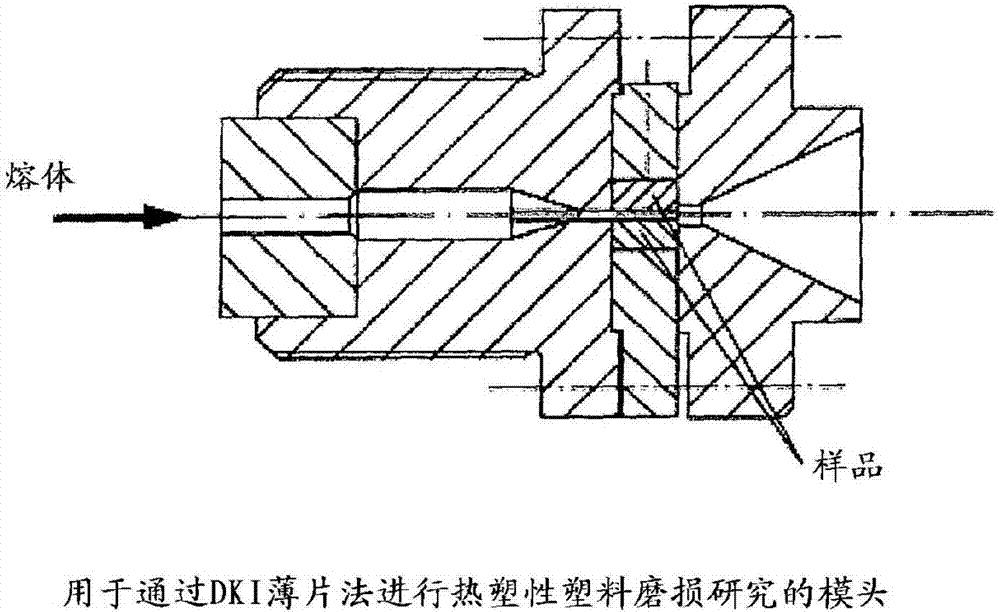

Image

Examples

Embodiment

[0203] 1. Components used

[0204] Commercially available polymers (pellets):

[0205] Polyamide 6.6 (PA 6.6-GV): A27 (from BASF AG, company D)

[0206] Polyphthalamide (PPA): HT plus M100 (obtained from Evonik, D company)

[0207] Fiberglass, PPG HP 3610EC 10 4.5mm (available from PPG Ind. Fiber Glass, NL Company)

[0208] Flame retardant (component A)):

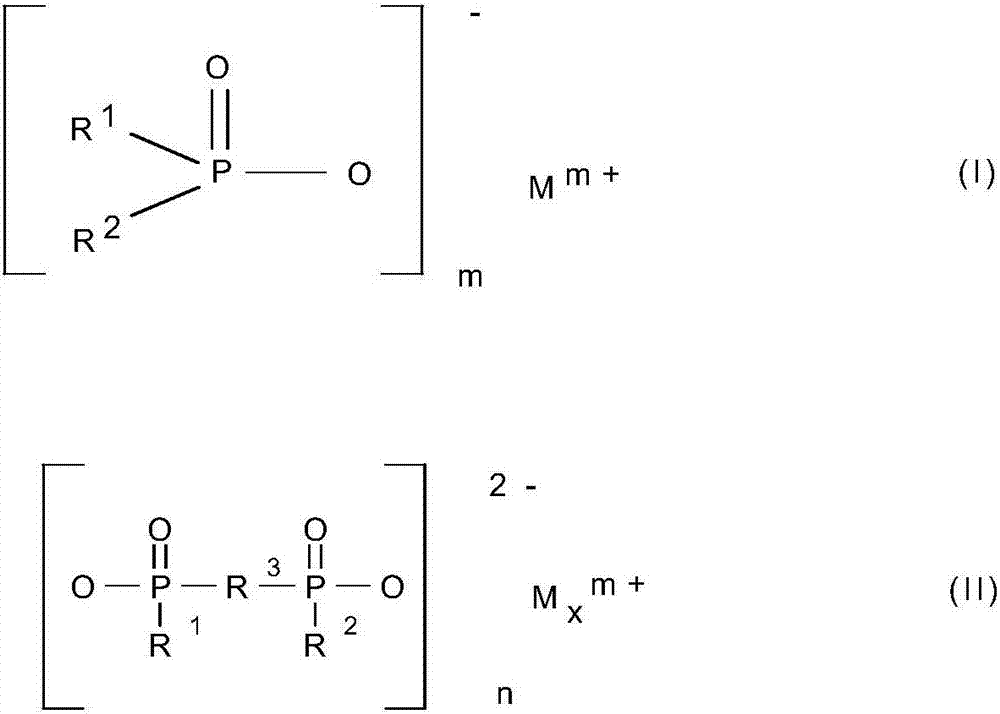

[0209] Aluminum salt of diethylphosphinic acid, hereinafter referred to as DEPAL

[0210] Flame retardant (component B)):

[0211] Aluminum salts of phosphorous acid, hereinafter called PHOPAL

[0212] Anti-corrosion additives (component C)):

[0213] Zinc borate ZB and 500, from Borax, USA

[0214] Zinc stannate H and S, obtained from William Blythe, UK Company

[0215] Boehmite: 20, 10, SB from Sasol, D Company

[0216] Chalk: CC-R from Omya Corporation,

[0217] Component D):

[0218] Melamine polyphosphate (known as MPP) 200 (obtained from BASF, D company)

[0219] Phosphonite or salt (...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com