Preparation method for Bi2S3/SnS2/Bi2O3 three-component composite photocatalyst capable of effectively degrading dye wastewater

A ternary composite, dye wastewater technology, applied in physical/chemical process catalysts, energy wastewater treatment, chemical instruments and methods, etc., to achieve the effect of strong market application value, stable performance, and wide absorption spectrum range

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

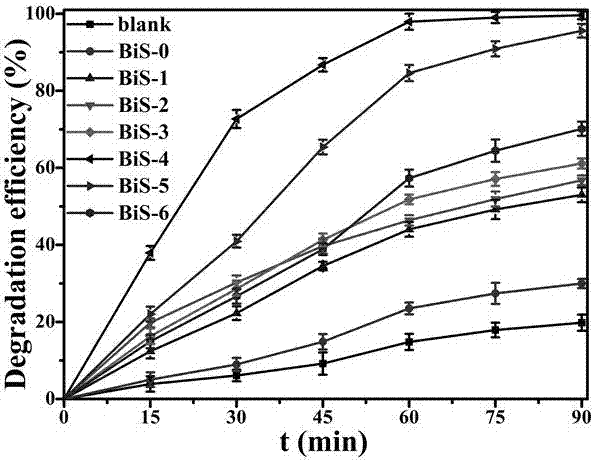

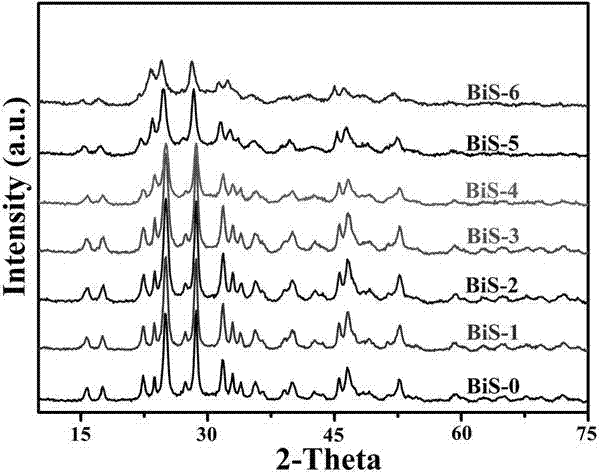

[0012] 1mM Bi(NO 3 ) 3 ·5H 2 O was dissolved in a mixed solution of 30mL ethanol and glycerol, then 3mM thiourea was added to the above solution and stirred magnetically for 40min, then the mixed solution was transferred to a polytetrafluoroethylene reactor at 180°C for reaction, after the reaction was completed Naturally cooled to room temperature, separated by filtration, washed three times with water and ethanol, then dried, and finally calcined at 280°C to obtain Bi 2 S 3 Photocatalyst (BiS-0 for short). After 90min of 350W Xe light irradiation, Bi 2 S 3 The photocatalyst can degrade 30% of RhB under simulated sunlight conditions.

Embodiment 2

[0014] 1mM Bi(NO 3 ) 3 ·5H 2 O was dissolved in a mixed solution of 30mL ethanol and glycerol, then 3mM thiourea was added to the above solution and magnetically stirred for 40min, then a certain amount (0.03mM, 0.05mM, 0.1mM, 0.15mM, 0.2mM or 0.25mM) SnCl 4 ·5H 2 O was dispersed in the above solution and continued magnetic stirring, and then the mixed solution was transferred to a polytetrafluoroethylene reactor at 180°C for reaction. After the reaction was completed, it was naturally cooled to room temperature, filtered and separated, washed with water and ethanol three times, then dried, and finally placed in Calcined at 280°C to get Bi 2 S 3 / SnS 2 / Bi 2 o 3 Ternary composite photocatalysts (abbreviated as BiS-1, BiS-2, BiS-3, BiS-4, BiS-5 and BiS-6, respectively). After 90min of 350W Xe light irradiation, the Bi with the best effect 2 S 3 / SnS 2 / Bi 2 o 3 The degradation rate of RhB by ternary composite photocatalyst under simulated sunlight conditions is hi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com