Preparation method of photocatalyst for ultraviolet light catalytic degradation of organic matters in oilfield waste liquid

A technology of catalysts and compounds, applied in physical/chemical process catalysts, chemical instruments and methods, chemical/physical processes, etc., can solve problems such as restricting the development of petroleum industry, polluting the environment, complex components, etc., and achieve excellent photocatalytic activity, The preparation method is simple and the effect of promoting absorption and utilization

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

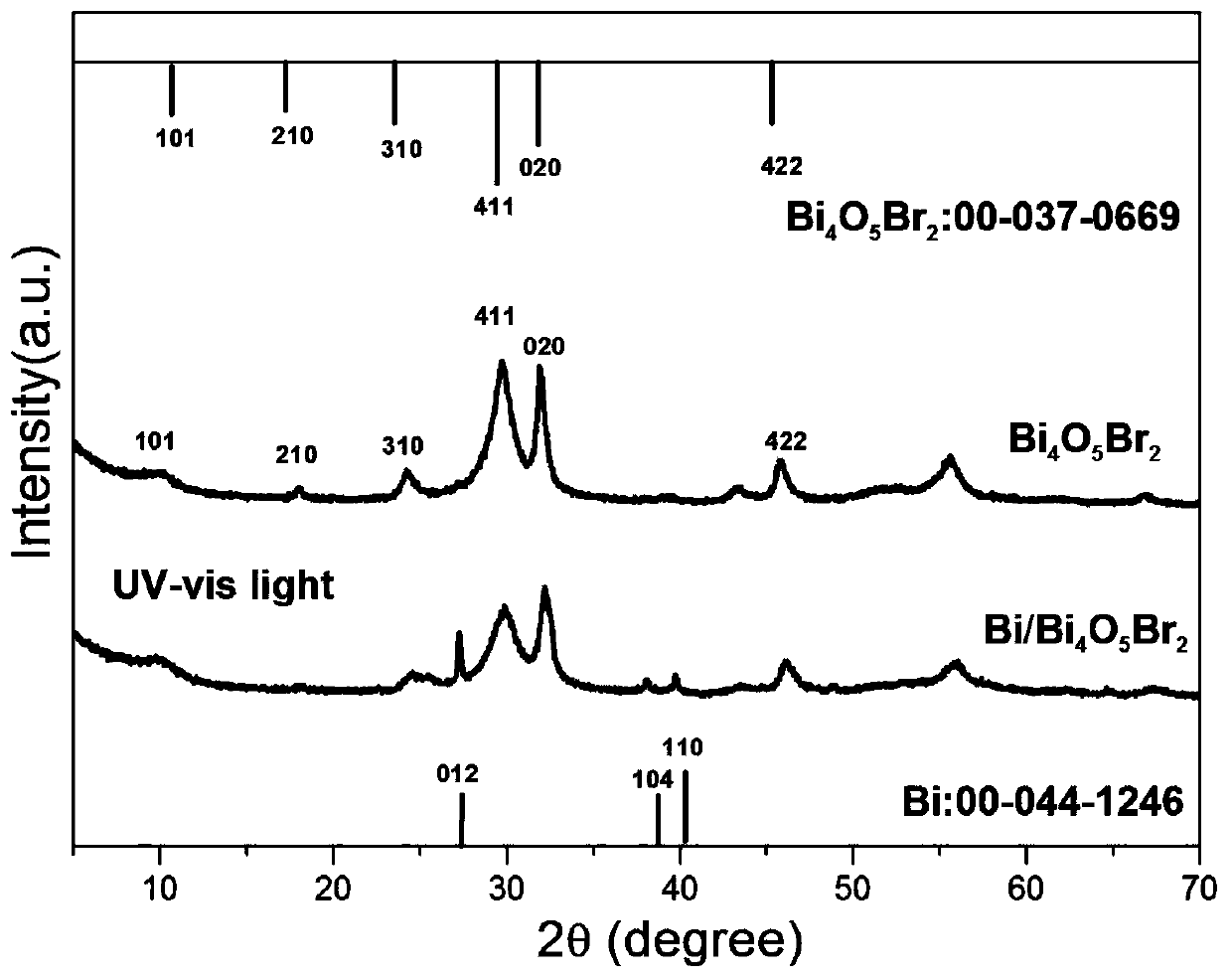

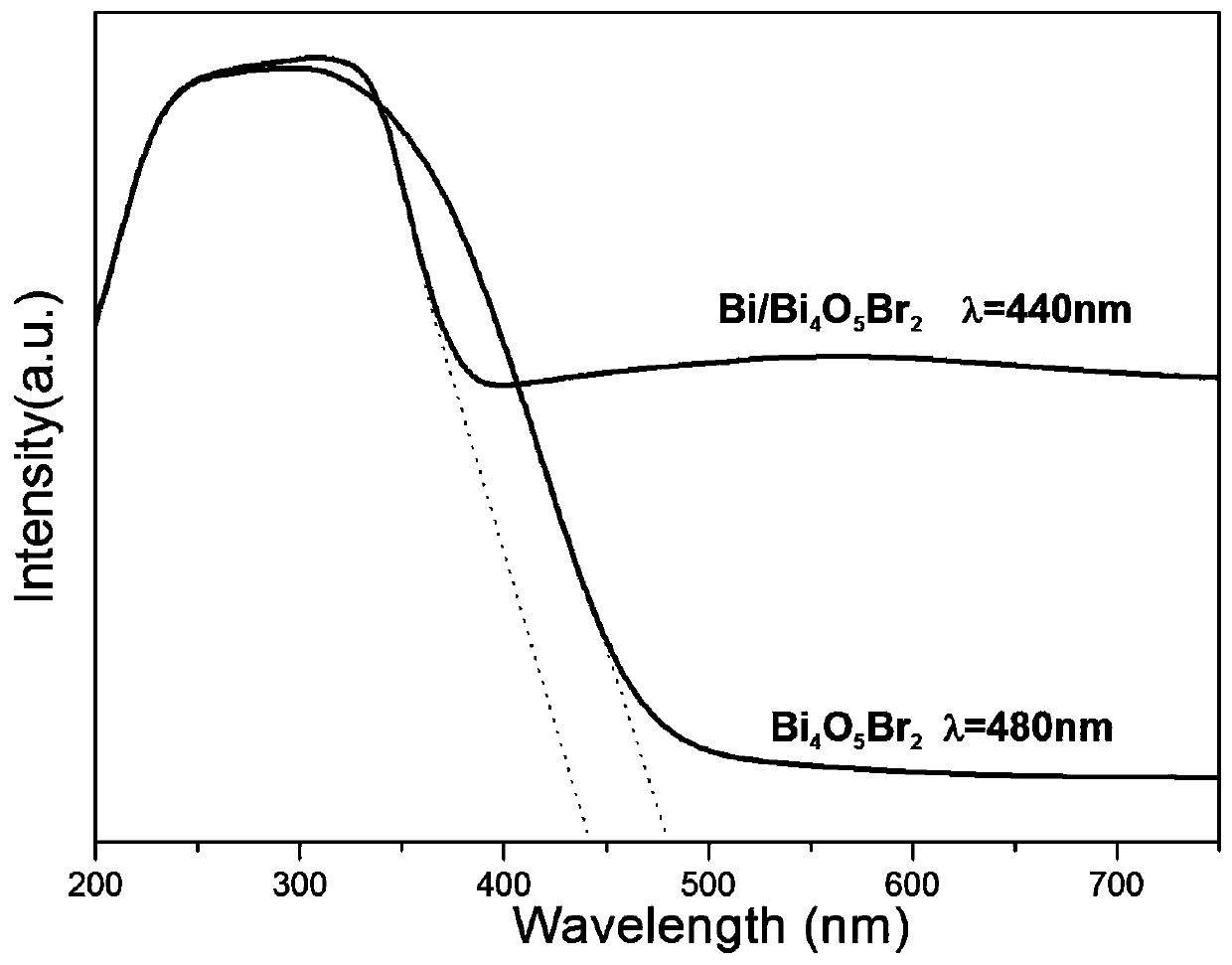

[0024] A Bi / Bi 4 o 5 Br 2 The preparation method of composite photocatalyst, the steps are as follows:

[0025] (1) Dissolve 1.9402g of bismuth nitrate pentahydrate in 35mL of glycerol with an analytical balance to obtain solution A; weigh 0.476g of potassium bromide and 0.0096g of isopropanol and dissolve in another 35mL of glycerin , to obtain solution B. (2) Start stirring the solution A and heat it to 50°C, add the solution B dropwise into the solution A with a rubber dropper, stir and react at a constant temperature of 50°C for 60min to obtain a mixed solution. (3) Transfer the mixed solution to a high-temperature and high-pressure reactor, react at 160°C for 16 hours, wash and collect the precipitate, and dry the precipitate in an oven at 70°C for 12 hours to obtain a precursor. (4) Weigh 0.4g of the precursor and add 100mL of distilled water, heat the water bath at 50°C, carry out the hydrolysis reaction under the irradiation of ultraviolet xenon lamp for 24h, and d...

Embodiment 2

[0027] A Bi / Bi 4 o 5 Br 2 The preparation method of composite photocatalyst, the steps are as follows:

[0028] Steps (1)-(3) are the same as in Example 1. Step (4): Weigh 0.4g of the precursor and add 100mL of distilled water. First, irradiate the reaction with UV lamp at the water bath temperature of 50°C for 7h, then raise the temperature of the water bath to 70°C, and continue to irradiate with the UV lamp for 17h. After the hydrolysis is completed, then transfer to Remove the water bath and turn off the UV lamp. After the aqueous solution is naturally cooled to room temperature, filter it, and dry the precipitate at 70°C for 12 hours. The black powder obtained is Bi / Bi 4 o 5 Br 2 composite photocatalyst.

Embodiment 3

[0030] Steps (1)-(3) are the same as in Example 1. Step (4): Weigh 0.4g of the precursor and add 100mL of distilled water, heat the water bath at 70°C, carry out the hydrolysis reaction under the irradiation of ultraviolet xenon lamp for 24h, and dry the obtained precipitate at 70°C for 12h, the obtained black powder is Bi / Bi 4 o 5 Br 2 composite photocatalyst.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Specific surface area | aaaaa | aaaaa |

| Specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com