Preparation method of Cu2O-CuO/bentonite photocatalytic composite material

A technology of composite materials and bentonite, which is applied in the field of preparation of Cu2O-CuO/bentonite photocatalytic composite materials, can solve the problems of easy agglomeration and difficult recycling, and achieve the effects of low cost, good photocatalytic activity, and simple and easy-to-operate preparation method

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

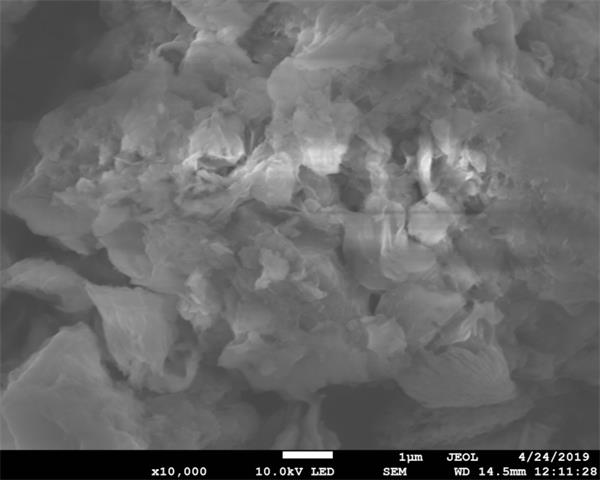

Image

Examples

Embodiment 1

[0016] Step S1: Put bentonite in deionized water, then add Na 2 CO 3 Make 12wt% bentonite slurry with bentonite at a mass ratio of 3%, stir at 60°C for 2 hours and let it stand overnight, then dilute the bentonite slurry to 20wt%, centrifuge and dry at 100°C, grind, and sieve to obtain Sodium bentonite;

[0017] Step S2: Dissolve copper nitrate in deionized water to prepare a 0.2 mol / L copper nitrate solution, then add 8 g of the sodium bentonite obtained in step S1 to 100 mL of copper nitrate solution, stir at room temperature for 2 hours, and then dissolve the reacted The sample was dried in a drying oven at 60°C, and then the dried sample was calcined in a muffle furnace at 300°C for 3 hours to obtain Cu 2 O-CuO / bentonite photocatalytic composites.

Embodiment 2

[0019] Step S1: Put bentonite in deionized water, then add Na 2 CO 3 Make 13wt% bentonite slurry with bentonite at a mass ratio of 4%, stir at 65°C for 3 hours and let it stand overnight, then dilute the bentonite slurry to 25wt%, centrifuge and dry at 105°C, grind, and sieve to obtain Sodium bentonite;

[0020] Step S2: Dissolve copper nitrate in deionized water to prepare a 0.3 mol / L copper nitrate solution, then add 9 g of the sodium bentonite obtained in step S1 to 100 mL of copper nitrate solution, stir at room temperature for 3 hours, and then dissolve the reacted The sample was dried in a drying oven at 70°C, and then the dried sample was calcined in a muffle furnace at 400°C for 4 hours to obtain Cu 2 O-CuO / bentonite photocatalytic composites.

Embodiment 3

[0022] Step S1: Put bentonite in deionized water, then add Na 2 CO 3 Make 15wt% bentonite slurry with bentonite at a mass ratio of 5%, stir at 70°C for 4 hours and let it stand overnight, then dilute the bentonite slurry to 30wt%, centrifuge and dry at 110°C, grind, and sieve to obtain Sodium bentonite;

[0023] Step S2: Dissolve copper nitrate in deionized water to prepare a 0.5 mol / L copper nitrate solution, then add 10 g of the sodium bentonite obtained in step S1 to 100 mL of copper nitrate solution, stir at room temperature for 4 hours, and then dissolve the reacted The sample was dried in a drying oven at 80°C, and then the dried sample was calcined in a muffle furnace at 600°C for 6 hours to obtain Cu 2 O-CuO / bentonite photocatalytic composites.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com