Visible light photocatalyst, modified PVDF ultrafiltration membrane and preparation method and application thereof

A technology of photocatalyst and nano-photocatalyst, which is applied in the field of PVDF ultrafiltration membrane and its preparation, to achieve the effects of inhibiting the formation of biofilm on the surface of the membrane, good photocatalytic activity, and remarkable photocatalytic performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0043] (1) Bi 2 MoO 6 / CuS nano photocatalyst preparation

[0044] Weigh 5.1g Bi(NO 3 ) 3 ·5H 2 O and 1.28g Na 2 MoO 4 2H 2 Dissolve O in 30mL of ethylene glycol and keep stirring for 50min, slowly add 60mL of ethanol and keep stirring for 30min to form a uniform solution; transfer the mixed solution to a reaction kettle for hydrothermal reaction at 160°C for 17h, and cool to room temperature Washed with ethanol and distilled water, and dried at 80 °C to give pale green Bi 2 MoO 6 Powder; weigh 1g Bi 2 MoO 6 The powder was dispersed in distilled water by ultrasound for 30min, and 0.042g Cu(NO 3 ) 2 ·3H 2 O and 0.013g thioacetamide and continue to ultrasonically disperse for 30min; transfer the mixed solution to a reaction kettle for hydrothermal reaction at 160°C for 4h, wash with distilled water after cooling to room temperature, and dry at 60°C to obtain Bi 2 MoO 6 / CuS nanophotocatalyst.

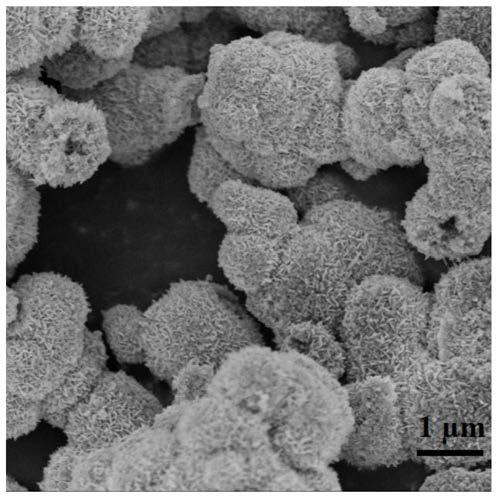

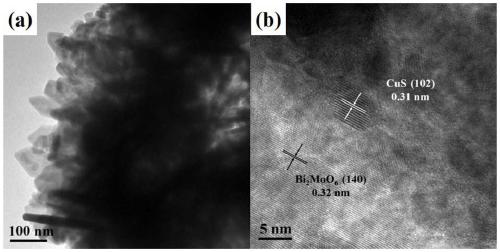

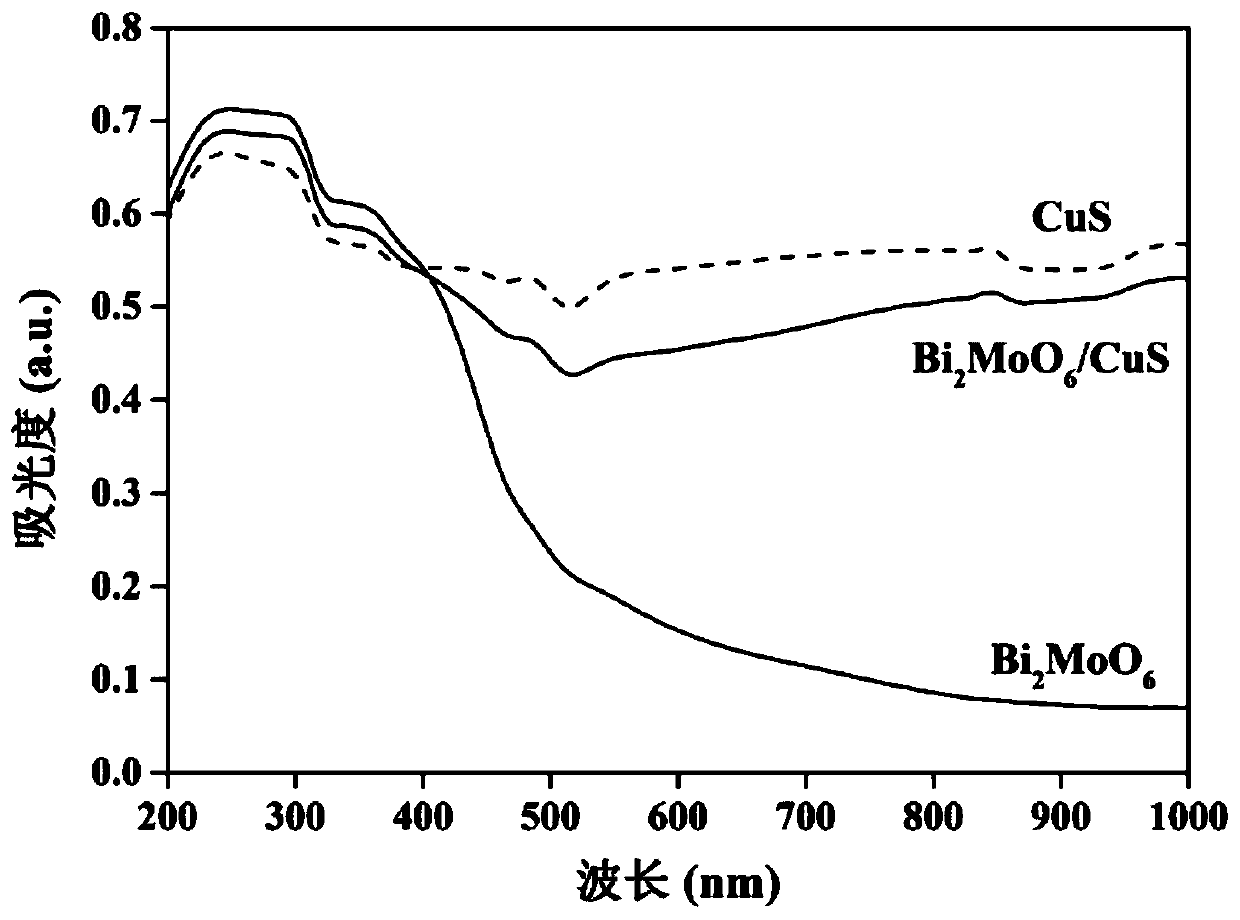

[0045] figure 1 Is the Bi prepared in this example 2 MoO 6 / CuS p...

Embodiment 2

[0050] (1) Bi 2 MoO 6 / CuS nano photocatalyst preparation

[0051] Weigh 5.1g Bi(NO 3 ) 3 ·5H 2 O and 1.02g Na 2 MoO 4 2H 2 Dissolve O in 20mL of ethylene glycol and keep stirring for 40min, slowly add 40mL of ethanol and keep stirring for 20min to form a uniform solution; transfer the mixed solution to a reaction kettle for hydrothermal reaction at 150°C for 16h, and cool to room temperature Washed with ethanol and distilled water, and dried at 70 °C to give pale green Bi 2 MoO 6 Powder; weigh 1g Bi 2 MoO 6 Powder ultrasonic 20min dispersed in distilled water, add 0.025g Cu(NO 3 ) 2 ·3H 2 O and 0.008g thioacetamide and continue to ultrasonically disperse for 20min; transfer the mixed solution to a reaction kettle for hydrothermal reaction at 150°C for 3h, wash with distilled water after cooling to room temperature, and dry at 50°C to obtain Bi 2 MoO 6 / CuS nanophotocatalyst.

[0052] (2) Bi 2 MoO 6 Preparation of CuS modified PVDF ultrafiltration membrane ...

Embodiment 3

[0055] (1) Bi 2 MoO 6 / CuS nano photocatalyst preparation

[0056] Weigh 5.1g Bi(NO 3 ) 3 ·5H 2 O and 1.7g Na 2 MoO 4 2H 2 Dissolve O in 30mL of ethylene glycol and keep stirring for 60min, slowly add 60mL of ethanol and keep stirring for 40min to form a uniform solution; transfer the mixed solution to a reaction kettle for hydrothermal reaction at 170°C for 18h, and cool to room temperature Washed with ethanol and distilled water, and dried at 90 °C to give pale green Bi 2 MoO 6 Powder; weigh 1g Bi 2 MoO 6 The powder was dispersed in distilled water by ultrasound for 40min, and 0.125g Cu(NO 3 ) 2 ·3H 2 O and 0.039g thioacetamide and continue to ultrasonically disperse for 40min; transfer the mixed solution to a reaction kettle for hydrothermal reaction at 170°C for 5h, wash with distilled water after cooling to room temperature, and dry at 70°C to obtain Bi 2 MoO 6 / CuS nanophotocatalyst.

[0057] (2) Bi 2 MoO 6 Preparation of CuS modified PVDF ultrafiltrat...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com