Guided stable anti-curling cutting guide

An anti-curling and stable technology, applied in the field of steel rolling, can solve the problem of low degree of automation of guide roll cooling, and achieve the effect of improving slitting effect, preventing edge warping and improving product quality.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

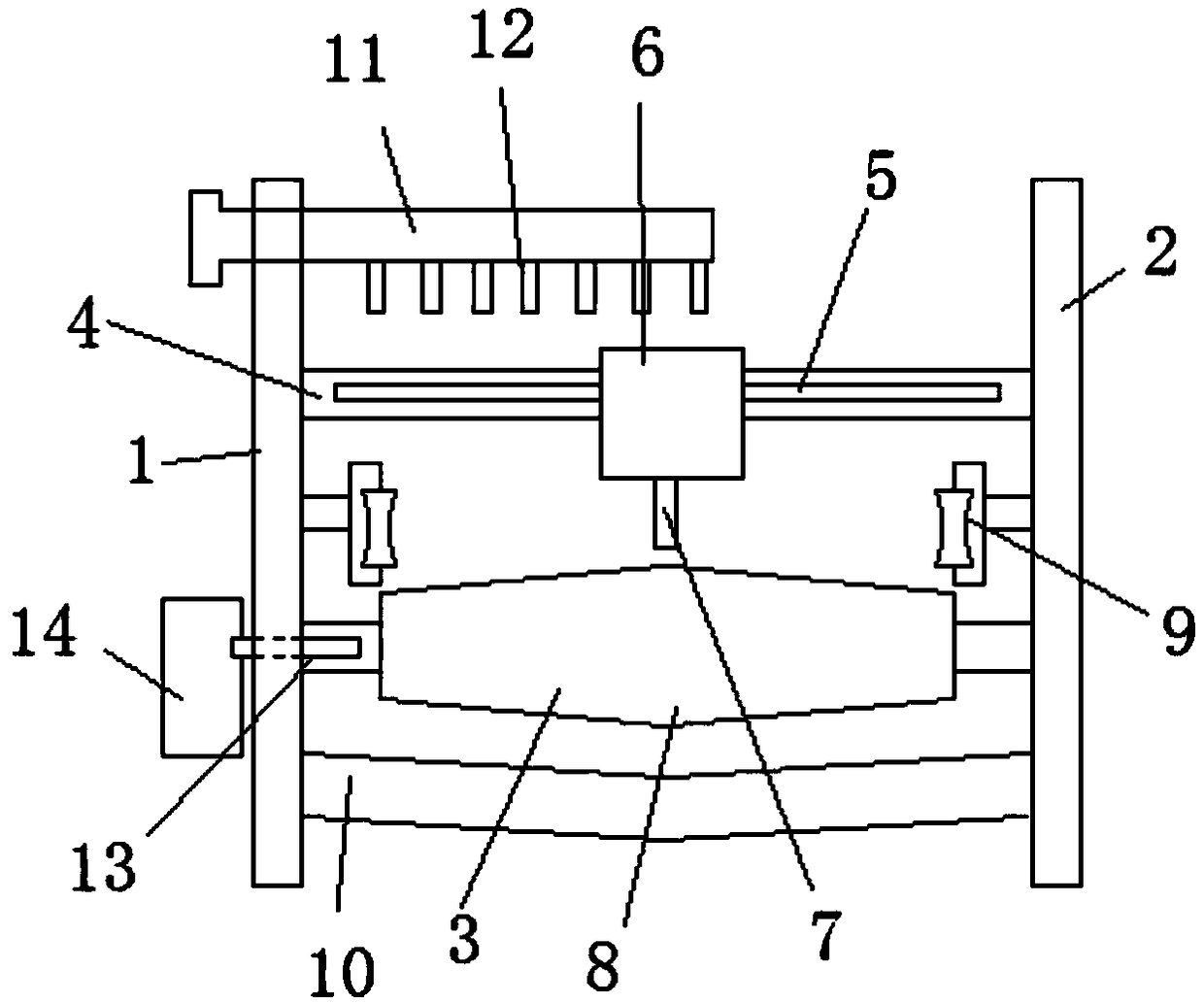

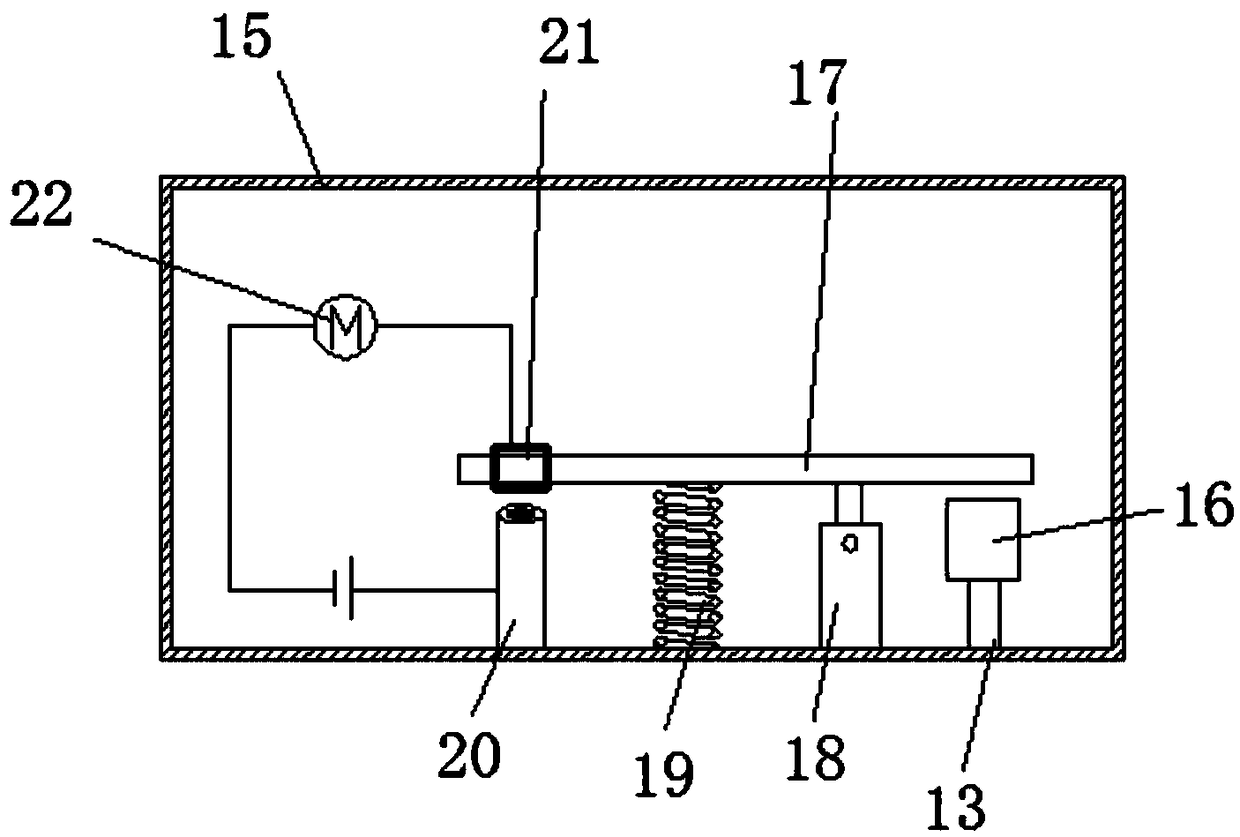

[0012] Referring to the accompanying drawings, a guiding and stable anti-rolling slitting guide includes left and right two guide roller arms 1, 2, and a guide roller 3 is arranged between the left and right two guide roller arms 1, 2. A sliding support bar 4 is provided above the guide roller 3 between the left and right two guide roller arms 1 and 2, and a chute 5 is provided on the side wall of the sliding support bar 4, and a sliding chute 5 is slidably installed in the chute 5. Block 6, the lower end of the slider 6 is fixedly equipped with a cutting knife 7, the middle section of the guide roller 3 protrudes 8 upwards, and the left and right guide roller arms on both sides of the guide roller 3 are provided with deviation correction Support 9, a cooling water pool 10 is provided below the guide roller 3, a cold water pipe 11 is arranged above the guide roller 3, and a plurality of spouts 12 are fixedly connected to the outer wall of the cold water pipe 11 near the guide r...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com