Heat treatment technique for improving low-temperature toughness of martensite-type heat-resistant steel containing large M23C6 precipitated phases

A low-temperature toughness and precipitated phase technology, which is applied in the field of heat treatment of steel materials, can solve the problems of difficult to eliminate large-sized M23C6 precipitated phases, low solid solution rate of precipitated phases, and difficulty in meeting standard requirements, so as to avoid re-precipitation and reduce lattice defects and quenching structure stress, the effect of shortening the soaking time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0030] A heat treatment technology for improving the low-temperature toughness of martensitic heat-resistant steel containing large-size M23C6 precipitates, the specific steps are as follows:

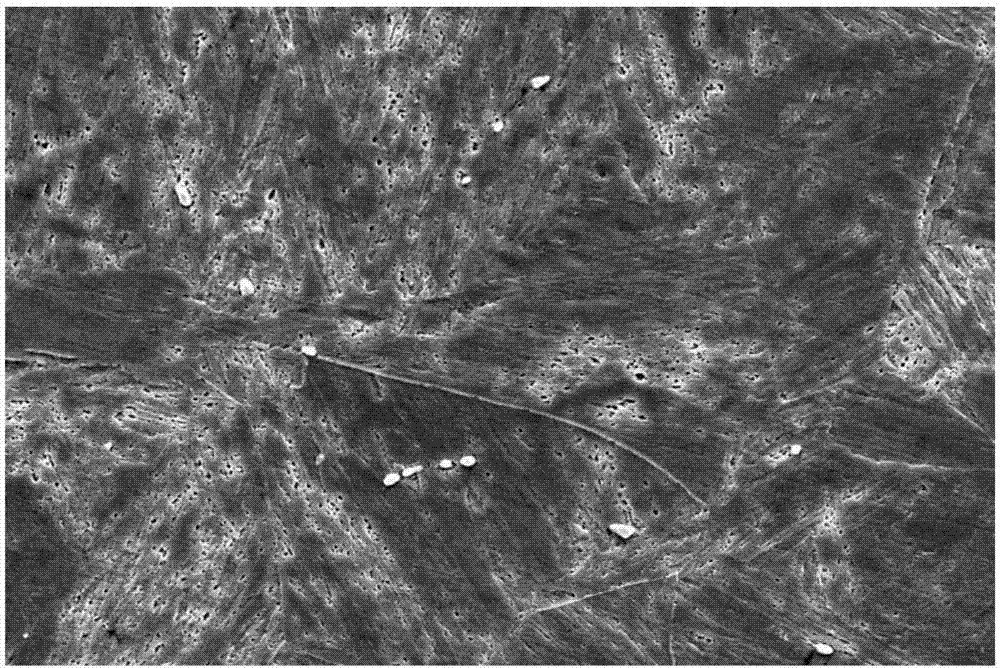

[0031] Step 1, primary quenching: the selected chemical composition is: (C: 0.10%, Si: 0.22%, Mn: 0.78%, Cr: 12.0%, Ni: 2.50%, Mo: 1.65%, V: 0.32%, N: 0.033 %), and containing 10Cr12Ni3Mo2VN martensitic heat-resistant steel forgings with large-sized M23C6 precipitates, in a box-type heating furnace, heated to 1100°C for 30 minutes to eliminate large-sized M23C6 precipitates in the structure and make the structure uniform melted, then oil-cooled and quenched;

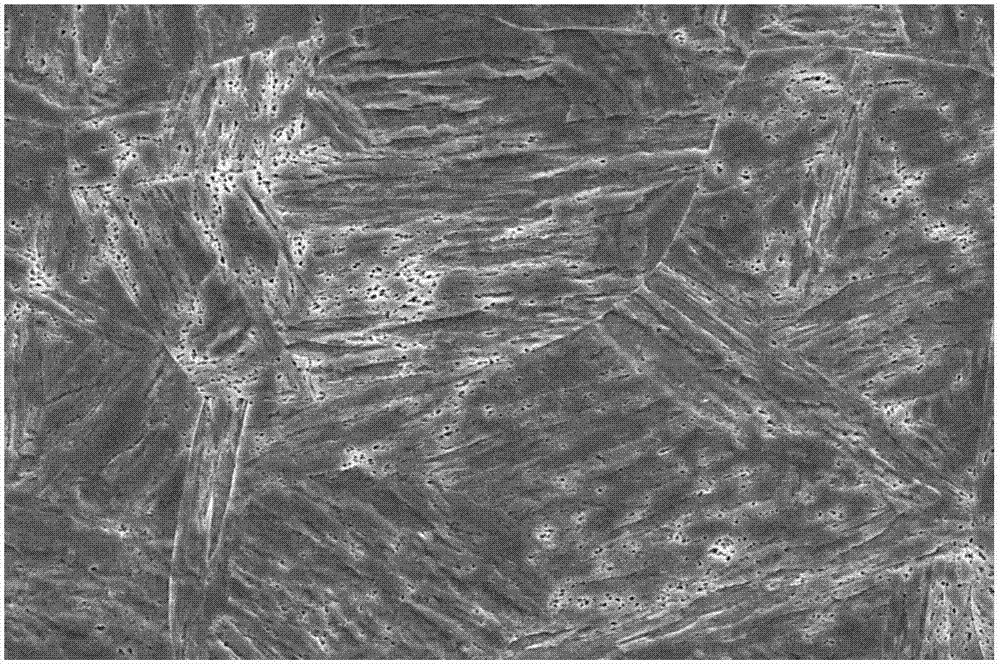

[0032] Step 2, secondary quenching: heat the 10Cr12Ni3Mo2VN steel after the primary quenching to 990°C for 45 minutes to refine the austenite grains, and then oil cooling and quenching;

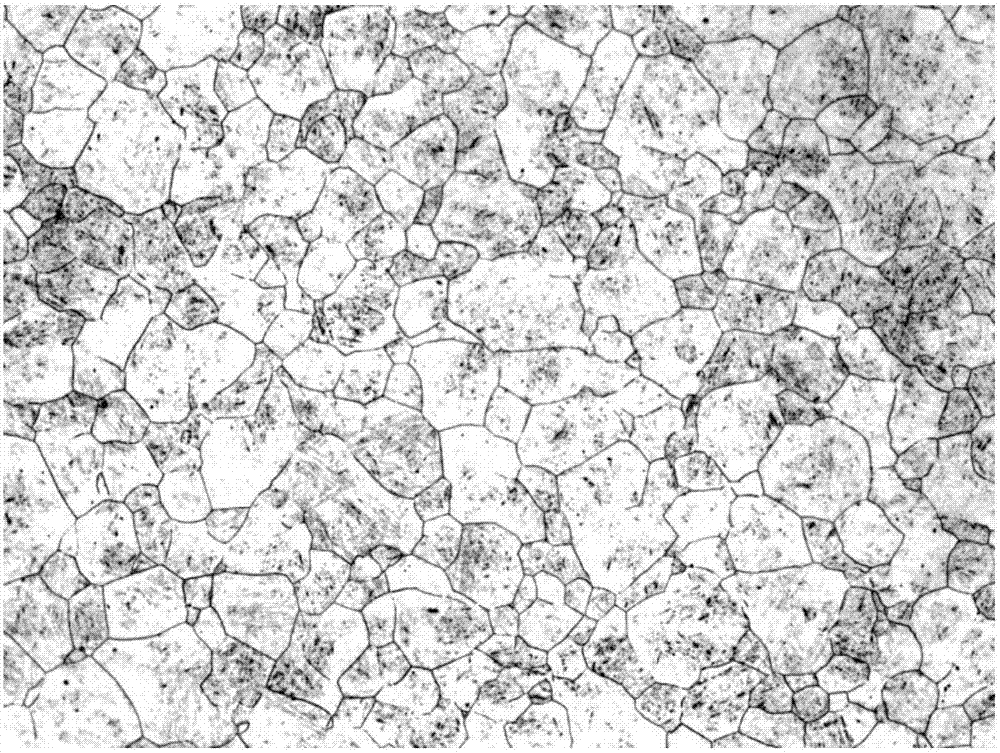

[0033]Step 3, high-temperature tempering: heat the 10Cr12Ni3Mo2VN steel after secondary quenching to 690°C for 120 minutes to fully recover the...

Embodiment 2

[0041] A heat treatment technology for improving the low-temperature toughness of martensitic heat-resistant steel containing large-size M23C6 precipitates, the specific steps are as follows:

[0042] Step 1, primary quenching: the selected chemical composition is: (C: 0.10%, Si: 0.22%, Mn: 0.78%, Cr: 12.0%, Ni: 2.50%, Mo: 1.65%, V: 0.32%, N: 0.033 %), and containing 10Cr12Ni3Mo2VN martensitic heat-resistant steel forgings with large-sized M23C6 precipitates, in a box-type heating furnace, heated to 1080 ° C for 30 minutes to eliminate large-sized M23C6 precipitates in the structure and make the structure uniform melted, then oil-cooled and quenched;

[0043] Step 2, secondary quenching: heat the 10Cr12Ni3Mo2VN steel after the primary quenching to 990°C for 40 minutes to refine the austenite grains, and then oil cooling and quenching;

[0044] Step 3, high-temperature tempering: heat the 10Cr12Ni3Mo2VN steel after secondary quenching to 690°C for 120 minutes to fully recover ...

Embodiment 3

[0046] A heat treatment technology for improving the low-temperature toughness of martensitic heat-resistant steel containing large-size M23C6 precipitates, the specific steps are as follows:

[0047] Step 1, primary quenching: the selected chemical composition is: (C: 0.10%, Si: 0.22%, Mn: 0.78%, Cr: 12.0%, Ni: 2.50%, Mo: 1.65%, V: 0.32%, N: 0.033 %), and containing 10Cr12Ni3Mo2VN martensitic heat-resistant steel forgings with large-sized M23C6 precipitates, in a box-type heating furnace, heated to 1100°C for 40 minutes to eliminate large-sized M23C6 precipitates in the structure and make the structure uniform melted, then oil-cooled and quenched;

[0048] Step 2, secondary quenching: heat the 10Cr12Ni3Mo2VN steel after the primary quenching to 980°C for 45 minutes to refine the austenite grains, and then oil cooling and quenching;

[0049] Step 3, high-temperature tempering: heat the 10Cr12Ni3Mo2VN steel after secondary quenching to 680°C for 120 minutes to fully recover th...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| size | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com