SMT processing system and SMT processing technology

A processing system and station technology, applied in the direction of instruments, electrical components, analysis materials, etc., can solve problems such as difficulty in recruiting workers, inability to monitor printing quality and tin printing capacity, rising labor costs, etc., to achieve simple system, shorten unstable test The effect of saving production stage and cost loss

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0020] The present invention will be further described below in conjunction with the accompanying drawings.

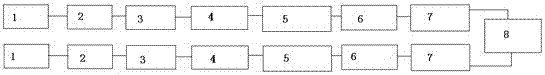

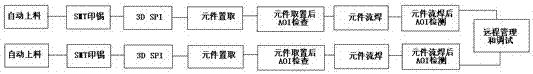

[0021] Depend on figure 1 It can be seen that an SMT processing system includes PCB automatic feeding machine 1, solder paste automatic printing machine 2, SPI automatic inspection machine 3, automatic placement machine 4, AOI inspection equipment 1, AOI inspection equipment 2 7 and component flow Soldering system 6, the PCB automatic board feeder 1 is connected to the solder paste automatic printing machine 2, the solder paste automatic printing machine 2 is connected to the SPI automatic detection machine 3, and the SPI automatic detection machine 3 is connected to the automatic placement machine 4 Connected, the automatic placement machine 4 is connected to the component flow soldering system 6 through the AOI inspection equipment one 5, and the component flow soldering system 6 is connected to the AOI inspection equipment two 7; the SPI automatic inspection machine...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com