Wet and dry dual use powder puff and preparing method thereof

A dry-wet dual-use, puff technology, applied in chemical instruments and methods, applications, household appliances, etc., can solve the problems of not being able to play both dry and wet at the same time, undisclosed powder puffs that can not be used arbitrarily, such as switching. To achieve the effect of a wide range of hardness, good wear resistance and good elasticity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

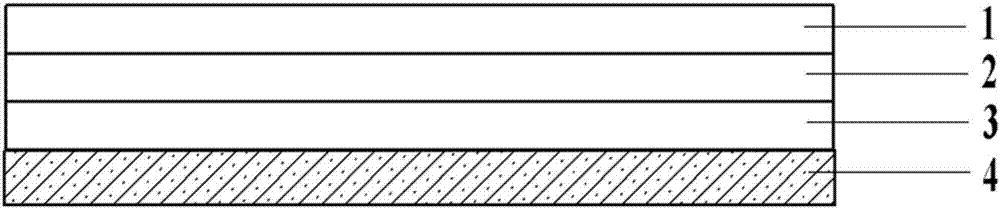

[0042] Such as figure 1 Shown, a kind of wet and dry powder puff, it comprises dry powder puff layer (the described dry powder puff layer comprises film layer 1, silica gel layer 2 and film layer 3 successively) and wet powder puff layer 4, described dry powder puff layer and wet powder puff layer The powder puff layers 4 are connected with an adhesive (that is, one side of the film layer 3 and the wet puff layer 4 are connected with an adhesive), and the film layer 1, the silica gel layer 2 and the film layer 3 are connected and fixed by hot pressing.

[0043] The material of the film layer 1 is a thermoplastic polyurethane elastomer (TPU), and the material of the film layer 3 is a thermoplastic polyurethane elastomer (TPU).

[0044] The material of the wet puff layer 4 is polyurethane sponge.

[0045] The adhesive is styrene-butadiene rubber.

[0046] The thickness of the film layer 1 is the same as that of the film layer 3, the thickness of the film layer 1 is 0.05 mm, a...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com