A kind of argon blowing refining method for producing SPHC steel

An argon blowing refining and steel type technology, applied in the direction of manufacturing converters, etc., can solve the problems of inability to carry out mass production, casing holes, heavy erosion of converter linings, etc., to prevent secondary oxidation of molten steel and slag roll problems, slow down The molten steel level fluctuates greatly, and the effect of promoting floating and removal

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

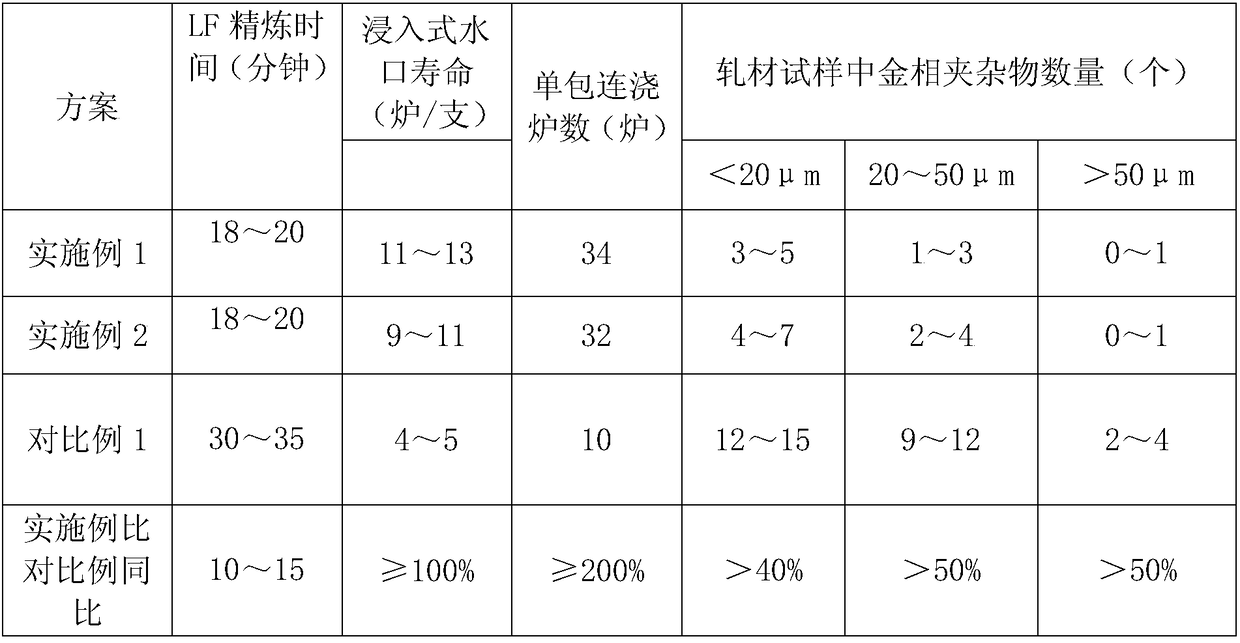

Examples

Embodiment 1

[0028] A kind of argon blowing refining method for producing SPHC steel grade, comprises the following steps:,

[0029] 1) Desulfurization of molten iron with a sulfur content of 0.012%;

[0030] 2) Al-Mn-Fe alloy is used for deoxidation when tapping the converter, and the addition amount is 3.3kg / t steel, so that the content of acid-soluble aluminum in the steel is controlled at 0.02%;

[0031] 3) When tapping the converter, add SPHC special pre-slag 500kg / furnace and 800Kg granular lime along with the steel flow, use a sliding plate to stop the slag when tapping, so that the thickness of the steel slag in the ladle is 60mm, the end point of the converter: carbon content 0.03%, oxygen content 600ppm, Tapping temperature 1630°C;

[0032] 4) Enter the LF refining furnace to measure the temperature and determine the oxygen: enter the LF refining furnace, blow the permeable brick at the bottom of the ladle into the station and stir for 2 minutes. temperature fixed oxygen;

[0...

Embodiment 2

[0044] A kind of molten steel purification method that is used for SPHC steel class as described in embodiment 1, difference is:

[0045] A kind of argon blowing refining method for producing SPHC steel grade, comprises the following steps:,

[0046] 1) Desulfurization of molten iron with a sulfur content of 0.010%;

[0047] 2) Al-Mn-Fe alloy is used for deoxidation when tapping the converter, and the addition amount is 3.5kg / t steel, so that the content of acid-soluble aluminum in the steel is controlled to 0.04%;

[0048] 3) When tapping the converter, add 800kg / furnace of special SPHC slag and 500Kg of granular lime along with the steel flow. The slag in the early stage and the slag in the later stage are all used to block the slag with a slide plate, so that the thickness of the steel slag in the ladle is 50mm. The control target of the converter end point: carbon content 0.04%, the oxygen content is 500ppm, and the tapping temperature is 1650℃;

[0049] 4) Enter the LF ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com