A kind of method that utilizes high manganese slag to prepare high carbon ferromanganese

A high-carbon ferromanganese and high-manganese technology, applied in the field of preparing high-carbon ferromanganese, can solve the problems of reduced furnace lining life, low economic benefit, low melting point of slag, etc., and achieve the effects of energy saving, significant economic benefit, and realization of regeneration and utilization.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

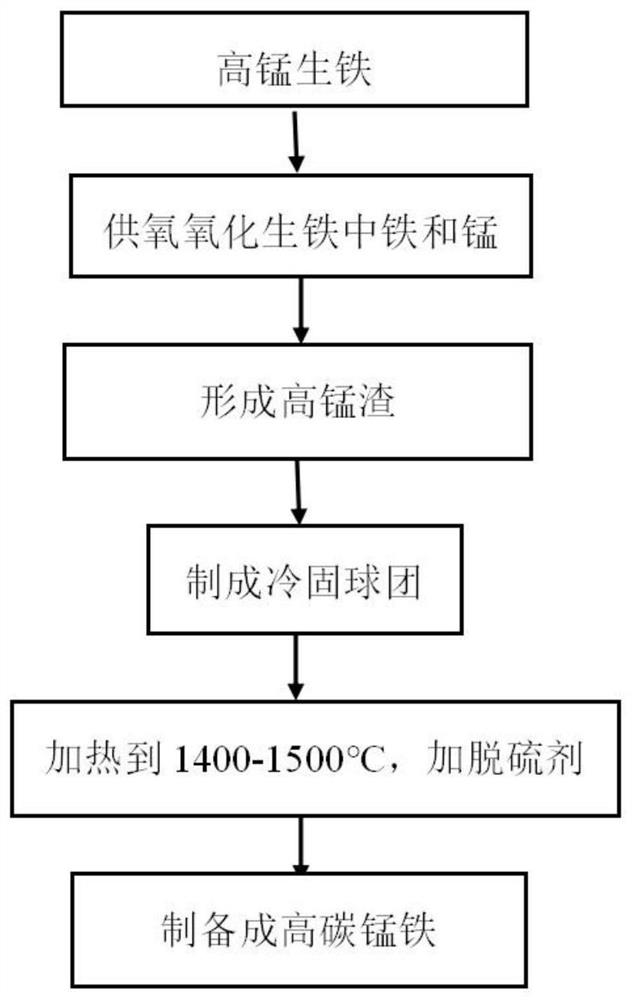

[0043] It should be noted that in S1, the preparation method of high manganese slag adopts oxygen supply to oxidize iron and manganese in high manganese iron water. Specifically, it includes the following steps: loading high manganese pig iron into an induction furnace, induction heating, heating power It is 110~130kw (for example, 120kw). When the molten iron is melted, measure the temperature of the molten iron. When the temperature of the molten iron is 1300°C, start blowing oxygen with an oxygen lance; the blowing process adopts a lower oxygen supply intensity O1 (for example, 0.5~ 2.0Nm 3 / (t·min)), the oxygen supply is 20~30m 3 / t, the oxygen blowing time is 10~60min; after the blowing starts, nitrogen is blown into the bottom blowing, and the gas supply intensity is 0.02~0.20Nm 3 / (t·min), until the end of blowing; pour out the high manganese slag, leaving semi-steel.

[0044] Specifically, during blowing, in order to lower the temperature of molten iron, iron ore (ma...

Embodiment 1

[0073] In the method for preparing high-carbon ferromanganese by utilizing high manganese slag provided in this embodiment, first, in a 500t induction furnace, oxygen supply is used to oxidize iron and manganese in high manganese ferromanganese water through an oxygen lance, and the generated iron oxide and manganese oxide enter the slag, pour After the slag is discharged, high manganese slag is formed as a raw material for preparing high carbon ferromanganese. Specifically, 200kg of high manganese pig iron, its chemical composition is C 4.46%, Si 0.01%, Mn 8.78%, P 0.18%, S 0.015%, the rest is Fe and trace unavoidable impurities; the oxygen supply intensity is 0.6Nm 3 / (t min), the end point temperature is controlled at 1350°C, iron ore is added to cool down during the blowing process, and the amount of iron ore added is 130kg / t; the oxygen blowing time is 34min, and the oxygen supply amount is 4.08m 3 , the bottom blowing gas supply intensity is 0.12Nm 3 / (t min); after blo...

Embodiment 2

[0076] In the method for preparing high-carbon ferromanganese by utilizing high manganese slag provided in this embodiment, first, in a 500t induction furnace, oxygen supply is used to oxidize iron and manganese in high manganese ferromanganese water through an oxygen lance, and the generated iron oxide and manganese oxide enter the slag, pour After the slag is discharged, high manganese slag is formed as a raw material for preparing high carbon ferromanganese. Specifically, 250kg of high manganese pig iron, its chemical composition is C 4.56%, Si 0.008%, Mn 8.89%, P 0.19%, S 0.017%, the rest is Fe and trace unavoidable impurities; the oxygen supply intensity is 1.0Nm 3 / (t min), the end point temperature is controlled at 1340°C, iron ore is added to cool down during the blowing process, and the amount of iron ore added is 138kg / t; the oxygen blowing time is 25min, and the oxygen supply amount is 6.25m 3 , the bottom blowing gas supply intensity is 0.12Nm 3 / (t·min). After b...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| melting point | aaaaa | aaaaa |

| melting point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com