Micro gap-free transmission type fatigue testing machine

A fatigue testing machine, transmission type technology, applied in the field of fatigue testing machine, can solve the problems of structural redundancy, obvious backlash, large volume, etc., achieve the effect of small size, light weight, and ensure the whole process of dynamic monitoring

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0027] In order to further understand the content, characteristics and effects of the present invention, the following examples are given, and detailed descriptions are as follows in conjunction with the accompanying drawings:

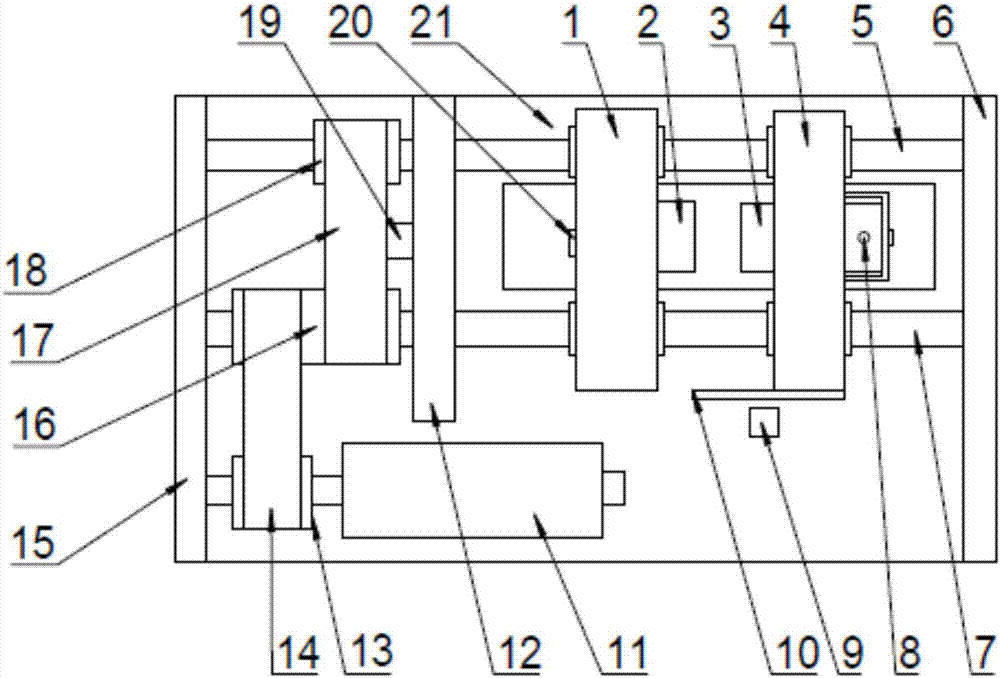

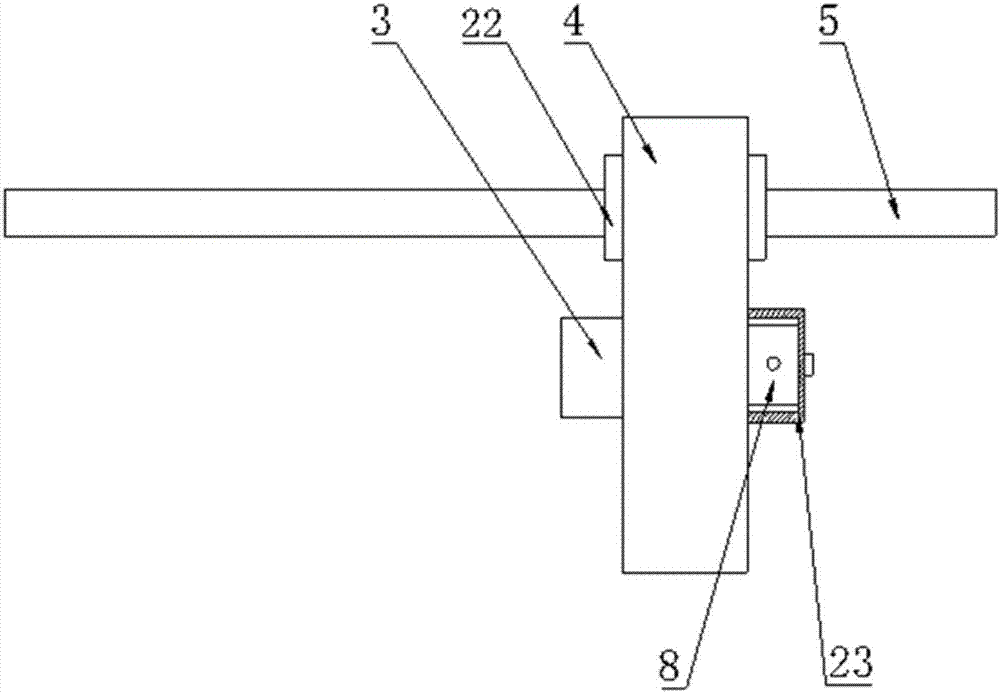

[0028] Such as figure 1 and figure 2 As shown, this embodiment provides a miniature non-backlash transmission fatigue testing machine, which includes a body, a symmetrical loading unit, a clamping unit, a signal detection unit, and a limit protection device.

[0029] The body is composed of a base plate 21 , a front baffle 15 , a rear baffle 6 and a support plate 12 . The bottom plate 21 is provided with a transmission window, which corresponds to the left clamp 2, the right clamp 3 and the lower part of the clamped sample, so that neutron diffraction, X-ray, synchrotron radiation light source, atomic force microscope and other instruments can pass through the transmission window. Transmission observation, so as to realize the whole dynamic monitori...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com