Graphene and/or carbon nanotube-containing air electrode, preparation method thereof and metal air battery

A carbon nanotube, air electrode technology, applied in battery electrodes, fuel cell type half cells and primary cell type half cells, circuits, etc. The effect of good thermal conductivity, excellent electrical conductivity and high discharge performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

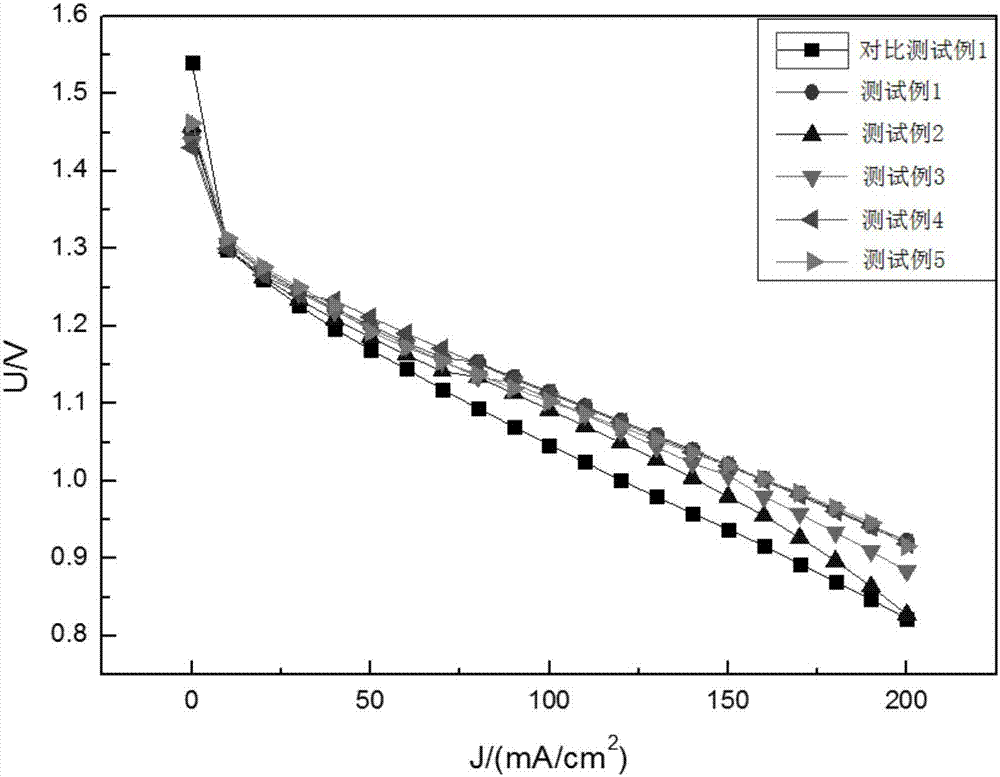

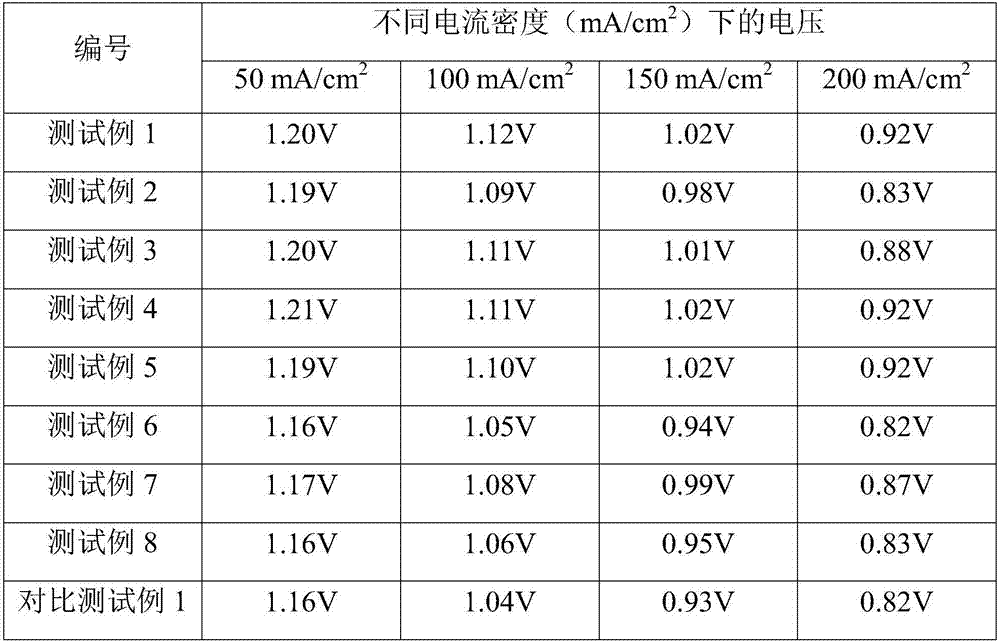

Examples

preparation example Construction

[0024] The second aspect of the present invention provides a method for preparing an air electrode containing graphene and / or carbon nanotubes, wherein the preparation method comprises the following steps:

[0025] (1) Conducting agent A, catalyst, binding agent A are mixed with absolute ethanol, and the obtained mixture is pressed into a membrane, the membrane is extracted in absolute alcohol, and then dried to obtain a catalytic layer, wherein , the conductive agent A includes graphene and / or carbon nanotubes;

[0026] (2) Provide a waterproof and breathable layer;

[0027] (3) The catalytic layer prepared in step (1), the current collector and the waterproof and breathable layer are sequentially stacked, and then pressed into shape.

[0028] According to the present invention, in order to further improve the electrical conductivity and thermal conductivity of the air electrode, preferably, the particle size of the graphene is 100m 2 / g, more preferably 150-300m 2 / g; pr...

Embodiment 1

[0051] The composition of catalytic layer: 70% by weight conductive agent A (graphene and gac, wherein, the consumption of graphene is 14% by weight, and graphene is in dispersion liquid form, and solid content is 5% by weight), 10% by weight of nanometer MnO 2 , 20% by weight PTFE.

[0052] Composition of the waterproof breathable layer: 40% by weight of conductive agent B (activated carbon and acetylene black), and 60% by weight of polyvinylidene fluoride.

[0053] (1) Preparation of catalytic layer

[0054] According to the above ratio, firstly, conductive agent A, nanometer MnO 2 Mix it with absolute ethanol in a beaker, stir and sonicate for 1 hour, then add polytetrafluoroethylene to the above mixture drop by drop, continue to stir and mix evenly, and then roll repeatedly to form a membrane with a thickness of 0.15mm, which is immersed in Extract in water and ethanol for 24 hours, take out the membrane, and dry at 60° C. for 12 hours to obtain a catalytic layer.

[00...

Embodiment 2

[0060] The composition of catalytic layer: 70% by weight conductive agent A (graphene, carbon nanotube and gac, wherein, the consumption of graphene and carbon nanotube is respectively 8 weight percent, graphene and carbon nanotube are in dispersion liquid form, solid content 10% by weight), 15% by weight nano MnO 2 , 15% by weight PTFE.

[0061] Composition of the waterproof breathable layer: 50% by weight of conductive agent B (activated carbon and acetylene black), 50% by weight of polyvinylidene fluoride.

[0062] (1) Preparation of catalytic layer

[0063] According to the above ratio, firstly, conductive agent A, nanometer MnO 2 Put it into a beaker with absolute ethanol, stir and ultrasonically for 2 hours, then add polytetrafluoroethylene to the above mixture drop by drop, continue to stir and mix evenly, and then roll repeatedly to form a membrane with a thickness of 0.2mm, immerse in anhydrous Extract in ethanol for 48 hours, take out the membrane, and dry at 80° ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

| Length | aaaaa | aaaaa |

| Specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com