New-type composite terminal

A composite terminal, a new type of technology, used in coupling devices, contact parts, fixed/insulated contact members, etc., can solve the problems of weak strength, poor contact, poor safety, etc., to achieve reasonable structure, prevent overheating deformation, and long service life. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

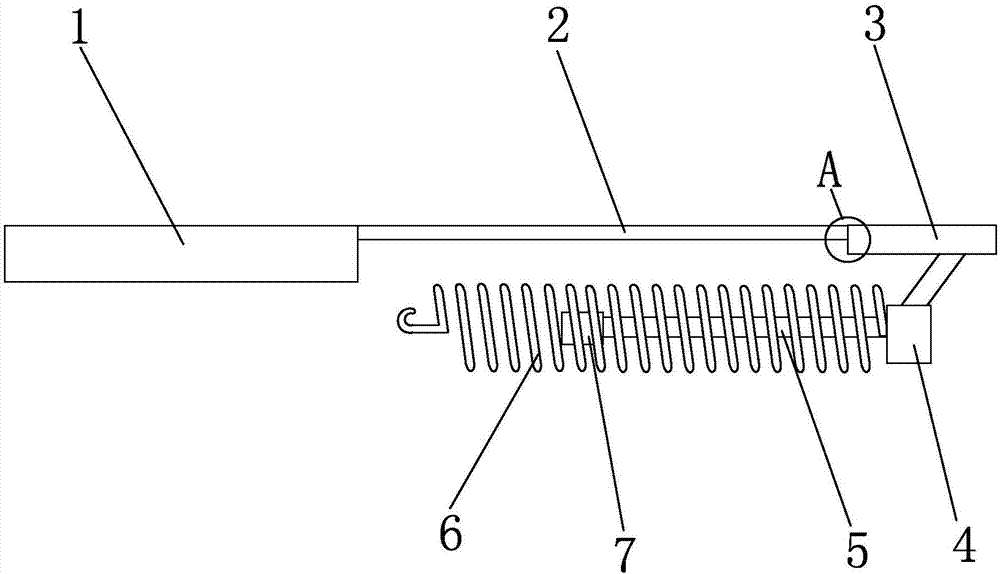

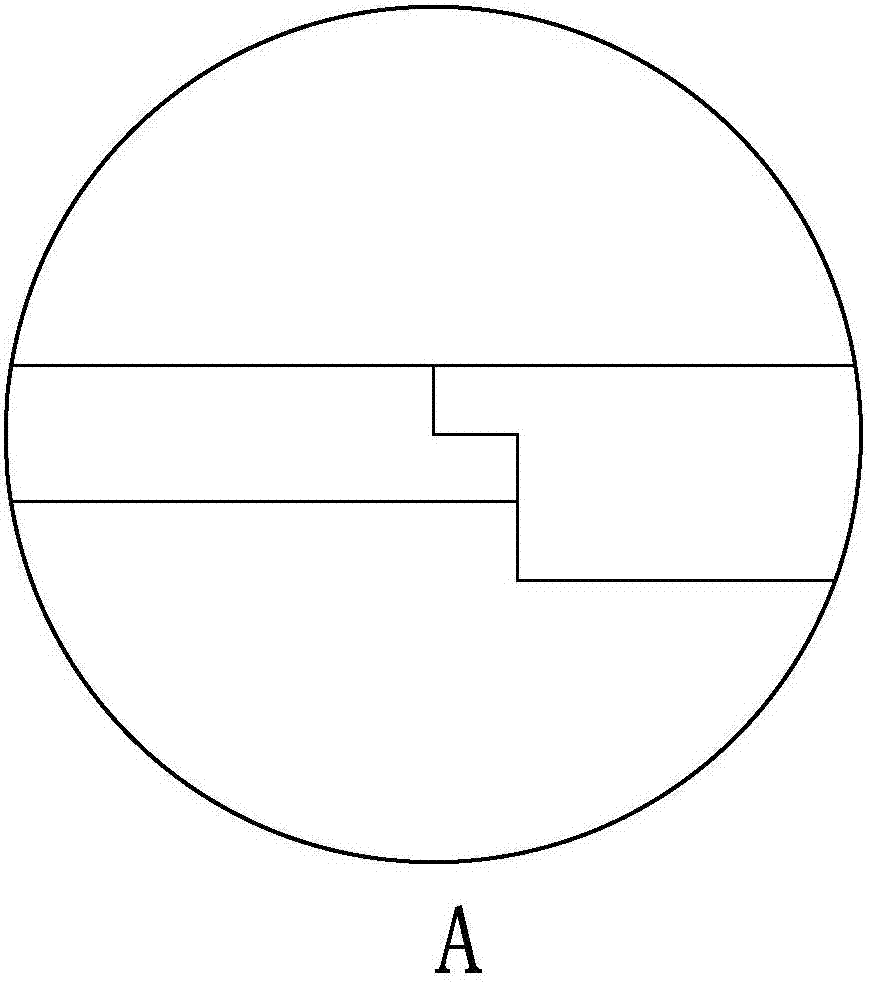

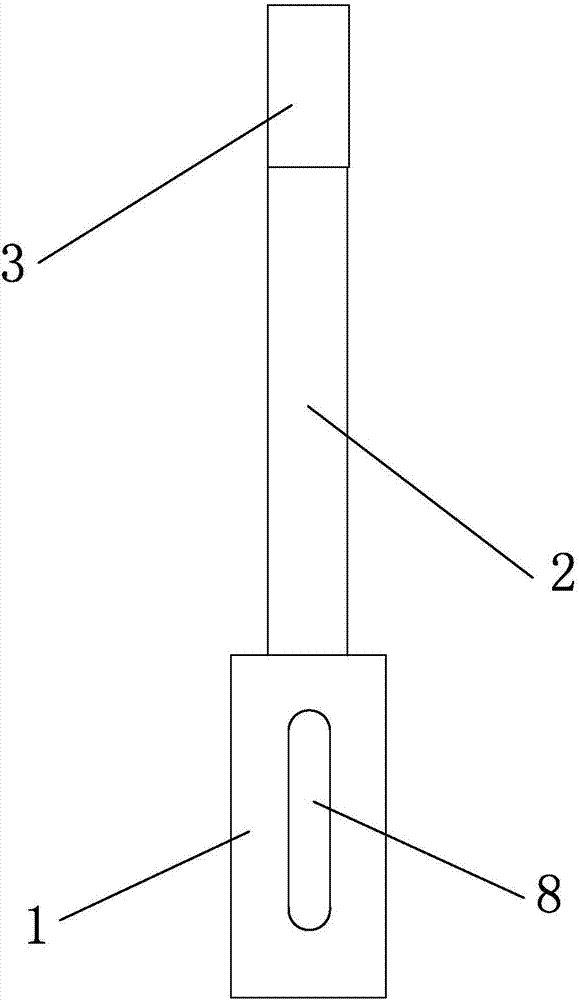

[0023] Combine Figure 1 to Figure 4 , The present invention is a new type of composite terminal, which includes a terminal body, a thermal contact piece 3, a connecting end 4, and a retractable spring 6. The terminal body includes a tail connecting section 1 and a front contact section 2. The terminal body has a strip-shaped plate structure, the tail connecting section 1 is connected with the front contact section 2, and the two sides of the tail connecting section 1 are arranged in parallel with each other and are bent at 90°. Preferably, a sliding groove 8 along the length of the terminal body is provided on the tail connecting section 1. The thermal touch sheet 3 is connected to the front contact section 2, and the contact surface of the thermal touch sheet 3 and the front contact section 2 is a stepped structure that cooperates with each other. The thermal contact piece 3 is made of nickel-chromium alloy, and the surface is coated with a polytetrafluoroethylene coating. ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com