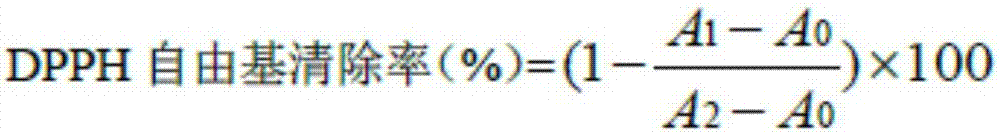

Method for improving DPPH free radical scavenging rate of Cantonese cured meat

A Cantonese-style cured meat, clearing rate technology, applied in food science, food preservation, application, etc., can solve problems such as unstable product quality, production is limited by seasons, etc., to improve antioxidant capacity, improve sensory quality, and delay poor quality change effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0028] 1. Cantonese-style bacon marinating formula: raw meat 100kg, salt 3kg, sugar 4kg, koji wine 2.5kg, soy sauce 3kg.

[0029] 2. The basic technique of Cantonese-style bacon: deboning and cutting meat strips: remove all rib bones, vertebrae and cartilage, trim neatly, and cut into 35cm long and 1cm wide meat blanks, and hang the top of the meat blanks with stainless steel hooks. Wash the meat strips: Soak the strips of pork ribs in clean water at about 30°C, rinse for about 2 minutes to remove the slick oil and dirt on the surface of the meat strips, and then take them out to drain the water. Tumbling: Dissolve the ingredients in the above formula with 10% water, pour into the tumbler, put the cut meat strips into the tumbler and knead for 2 hours, tumbling for 20 minutes, with an interval of 10 minutes, take it out to hang, and wait for baking. Baking: 60°C, 55% humidity, bake for 28 hours, and send it to the refrigerator to cool. Packing: Vacuum packing.

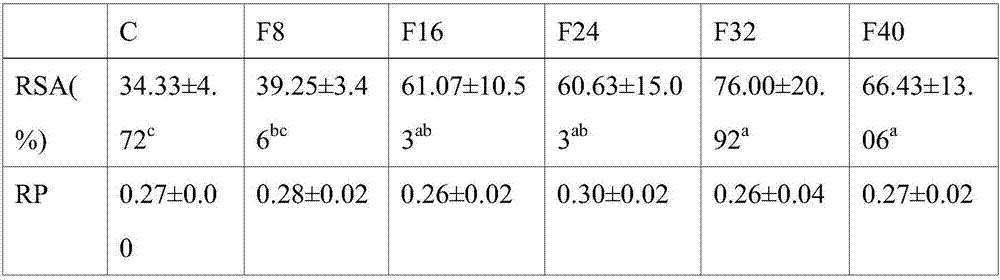

[0030] 3. Th...

Embodiment 2

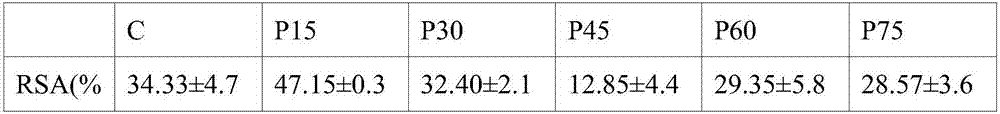

[0040] The method is the same as in Example 1, wherein, the control group (C) is made according to the basic formula (salt is 1.5kg), and the treatment group adds 15AU / 1000kg (P15), 30AU / 1000kg (P30), 45AU / 1000kg (P45), 60AU / 1000kg (P60) and 75AU / 1000kg (P75) complex protease. The operation was repeated three times.

[0041] The effect of compound protease on the antioxidant capacity of Cantonese-style bacon is shown in Table 3. According to Table 3, compared with the control group, adding a small amount of compound protease can significantly (P0.05), see P60 and P75 groups. Compared with the control group, adding a small amount of compound protease to the P60 group had no significant effect on the reducing power of Cantonese-style bacon (P>0.05), and continued addition would significantly (P<0.05) reduce the reducing power of Cantonese-style bacon, see P75 group.

[0042] Table 3 The effect of compound protease addition amount on the antioxidant capacity of Cantonese-style ...

Embodiment 3

[0051] The method is the same as in Example 1, wherein, the addition amount of flavor protease, the addition amount of compound protease and the baking temperature are used as operating variable conditions, and the results are shown in Table 5.

[0052] Table 5 L 9 (3 3 ) Orthogonal experimental design and experimental results

[0053]

[0054]

[0055] SPSS 22.0.0 was used to conduct variance analysis on the results, and the results of variance analysis are shown in Table 6.

[0056] Table 6 Analysis of variance table of DPPH free radical scavenging rate test

[0057]

[0058] a. R squared = 0.960 (adjusted R squared = 0.839)

[0059] It can be seen from the range analysis results in Table 6 that R X3 >R X1 >R X2 , then the influence of the three factors on the DPPH·scavenging ability of Cantonese-style bacon is as follows: baking temperature (X3) > flavor protease addition (X1) > compound protease addition (X2). Among the three factors, the influence of bakin...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com