Centrifugal extractor

A centrifugal extractor and rack technology, used in solvent extraction, liquid solution solvent extraction, separation methods, etc., can solve the problems of limiting the rotational speed of the drum, vibration, and vibration of the centrifugal extractor, reducing vibration, improving mixing and Separation effect, easy installation and positioning effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0018] Specific embodiments of the present invention will be described in detail below in conjunction with the accompanying drawings.

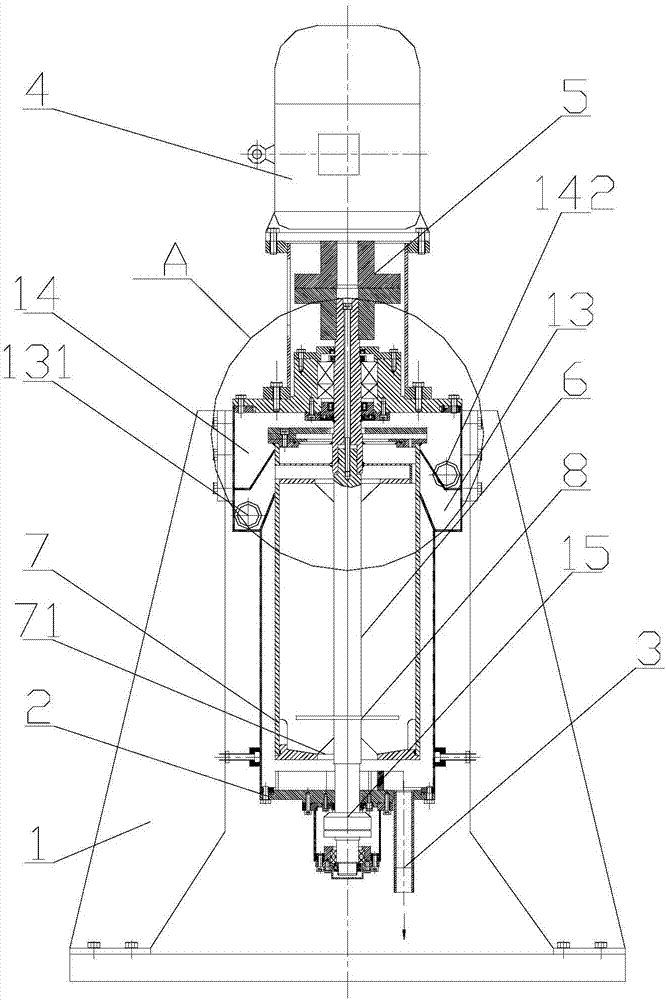

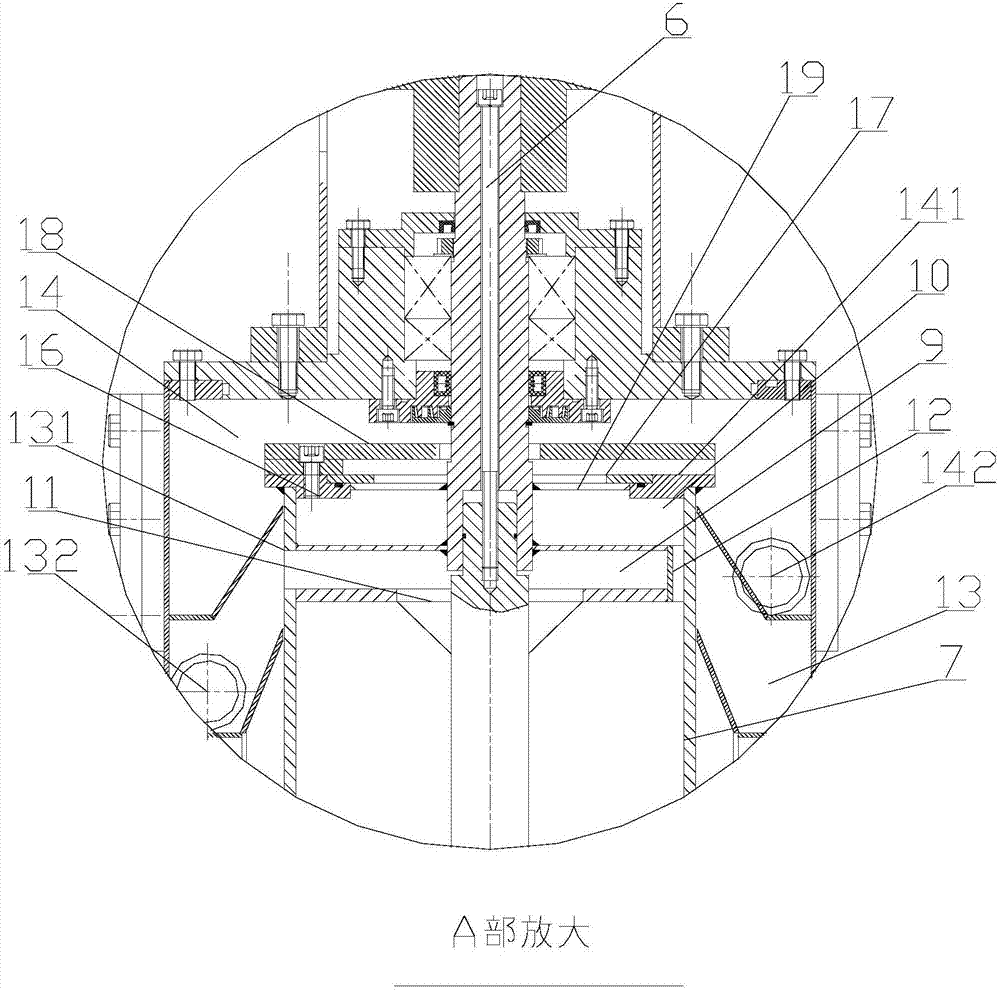

[0019] Such as Figure 1-2 Shown, a kind of centrifugal extraction machine comprises frame 1, and frame 1 is provided with the cylindrical feed tube 2 that axis is arranged along vertical direction, is provided with light phase liquid inlet 21 and heavy phase liquid inlet 2 on the feed tube 2. Phase liquid inlet 22. The bottom of the feeding cylinder 2 is provided with a sewage pipe 3 . The top of the frame 1 is provided with a driving motor 4 , and the output shaft of the driving motor 4 is connected with the rotating shaft 6 through a coupling 5 . The other end of the rotating shaft 6 penetrates into the feeding cylinder 2 and is connected at the lower end of the feeding cylinder 2 . The part where the rotating shaft 6 passes through the feeding cylinder 2 is provided with a positioning assembly 15 that matches the outer bottom surface of...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com