Dense lanthanum flint optical glass as well as preparation method and optical element thereof

An optical glass, flint technology, applied in optical components, glass manufacturing equipment, glass pressing, etc., can solve the problem of glass devitrification resistance and chemical stability deterioration, glass crystallization performance deterioration, damage to glass network structure, etc. problems, to achieve the effects of low cost, weight reduction, and low crystallization temperature

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0060] The present invention also provides a method for preparing the optical glass according to the present invention, which includes: weighing each component according to the proportion, mixing them uniformly, melting them, and then pouring or slipping them into a molding mold, or directly pressing them into shape.

[0061] Specifically, they are weighed according to the specified ratio, mixed into batch materials, and melted in a crucible made of platinum at a temperature of 1230-1280 ° C. After the raw materials are melted into glass liquid, the temperature is raised to 1280-1330 ° C. ℃ and turn on the stirrer made of platinum to stir and homogenize, and the stirring time is controlled at 5-10h. After the stirring is completed, raise the temperature to 1320-1370°C and keep it warm for 5-10 hours to clarify and make the bubbles fully float up, then lower the temperature to 1180-1230°C and pour or leak into the molding mold or press molding, and finally anneal After processi...

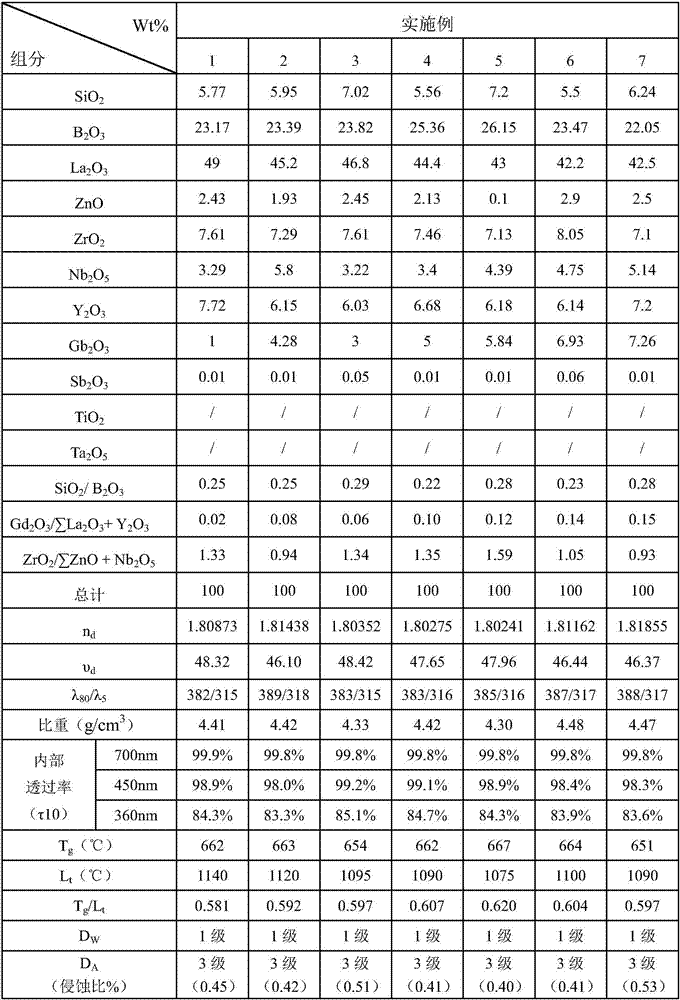

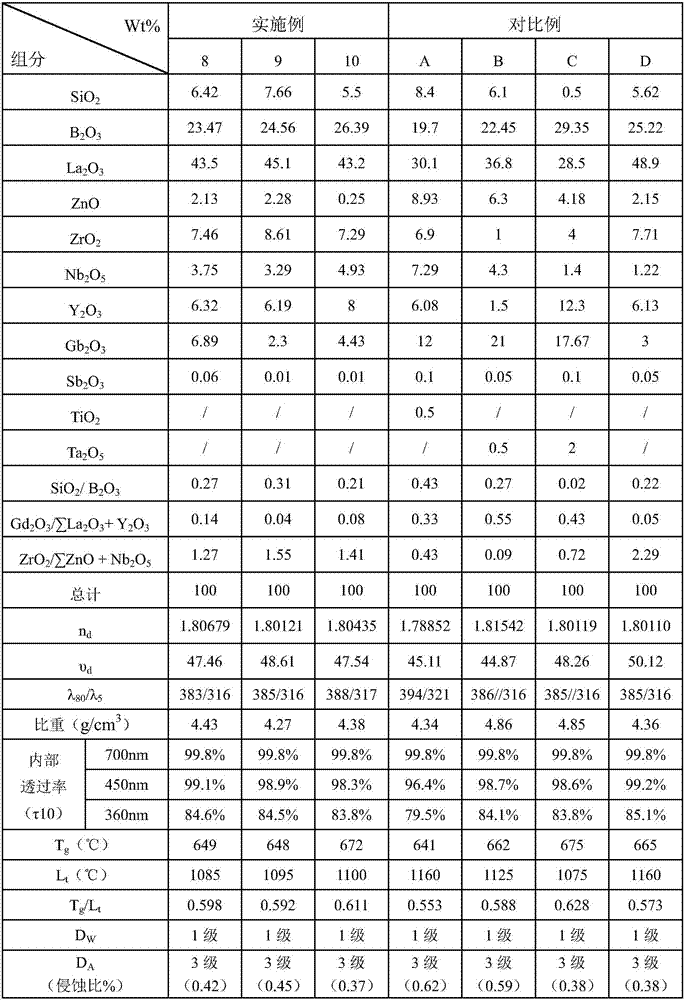

Embodiment 1~10

[0066] The raw materials corresponding to the components in Table 1 and Table 2 below are weighed and mixed according to the specified ratio to form batch materials, and then melted in a crucible made of platinum at a temperature of 1250°C. After the raw materials are melted into molten glass , raise the temperature to 1310°C and turn on the stirrer made of platinum to stir and homogenize, and the stirring time is controlled at 8h. After the stirring is completed, raise the temperature to 1350°C and keep it warm for 8 hours to clarify, so that the bubbles fully float up, then lower the temperature to 1210°C and pour or leak into the molding mold or press molding, and finally process after annealing to obtain Example 1 ~10 optical glass.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com