Green brick of high white imitated jade polished brick, and preparation method of ceramic tile

A technology of imitating jade and polished bricks, which is applied in the field of architectural ceramics, can solve the problems of jade texture not being realistic and delicate, easy to produce karst caves, impurities, low gloss and whiteness, etc., to achieve rich layout layering, rich layering, melting good sex effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

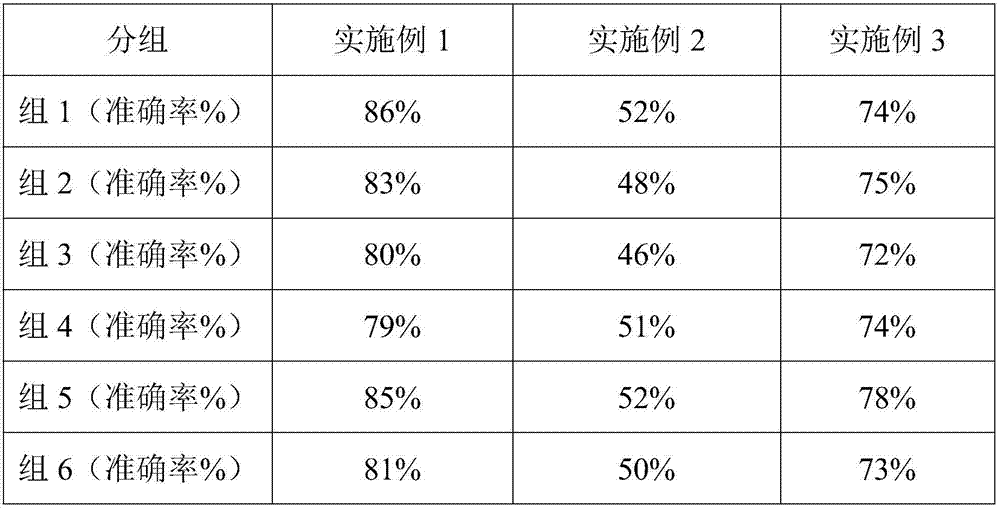

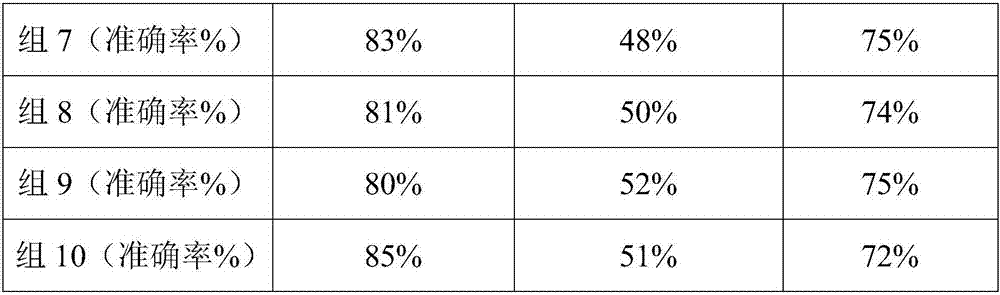

Examples

preparation example Construction

[0041] A preparation method for high-white imitation jade polished tiles, comprising the steps of:

[0042] (1) Preparation of mixed powder: weigh the raw materials equipped with high-temperature material and the raw material of high-white transparent material according to the proportion, and obtain slurry through ball milling respectively, and then spray dry to obtain high-temperature powder and high-white transparent powder; After the high-temperature powder and the high-white transparent powder are homogenized and stale, they are mixed according to a mass ratio of (40-50): 100 to obtain a mixed powder;

[0043] (2) the mixed powder is obtained through distributing, pressing and firing at high temperature to obtain adobe;

[0044] (3) The brick adobe is subjected to surface polishing and edging treatment to obtain a high-white imitation jade polished brick.

[0045] The preparation method of the high-white imitation jade polished brick proposed by the present invention firs...

Embodiment 1-

[0050] Embodiment 1-a kind of preparation method of high white imitation jade polished brick, comprises the steps:

[0051] (1) Preparation of mixed powder: Weigh the raw materials equipped with high-temperature materials and high-white transparent materials according to the proportion, that is, calculate according to mass percentage, mix 15% clay, 20% medium-temperature sand, 12% terrazzo powder, 10% long Stone, 18% high-temperature sand, 21.5% quartz, 3% talc and 0.5% sodium tripolyphosphate are used as the raw material formula of high-temperature material; 25% clay, 12% medium-temperature sand, 19.7% water-milled high-potassium stone powder, 15% feldspar, 13% Jiangxi high lithium white sand, 10% quartz, 2% talc, 3% calcite and 0.3% sodium tripolyphosphate as the raw material formula of high white transparent material;

[0052] The raw material of the high-temperature material and the raw material of the high-white transparent material are sieved through a ball mill to obtai...

Embodiment 2- 1

[0056] Embodiment 2-a kind of preparation method of high white imitation jade polished tile, comprises the steps:

[0057] (1) Preparation of mixed powder: Weigh the raw materials equipped with high-temperature materials and high-white transparent materials according to the proportion, that is, calculate according to mass percentage, mix 15% clay, 23% medium-temperature sand, 12% terrazzo powder, 16.1% long Stone, 16% high-temperature sand, 15% quartz, 2.5% talc and 0.4% sodium tripolyphosphate are used as the raw material formula of high-temperature material; 15% clay, 8% medium-temperature sand, 18.7% water-milled high-potassium stone powder, 30% feldspar, 13% Jiangxi high lithium white sand, 10% quartz, 2% talc, 3% calcite and 0.3% sodium tripolyphosphate as the raw material formula of high white transparent material;

[0058] The raw material of the high-temperature material and the raw material of the high-white transparent material are sieved through a ball mill to obtai...

PUM

| Property | Measurement | Unit |

|---|---|---|

| whiteness | aaaaa | aaaaa |

| gloss | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com