Edible alcohol fermentation production process

A technology of edible alcohol and production process, which is applied in the field of edible alcohol fermentation production process, can solve the problems of low nutritional content and poor taste, and achieve the effect of high nutritional value, sweet taste and good taste

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

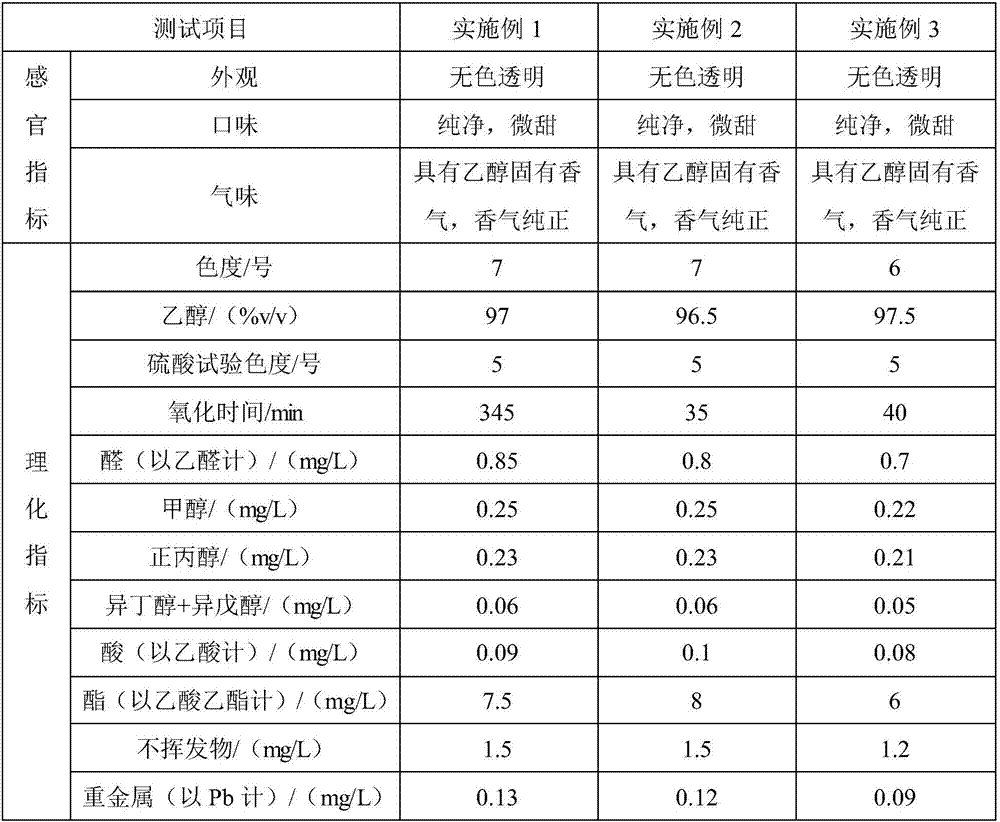

Embodiment 1

[0025] The invention provides a kind of edible alcohol fermentation production process, concrete steps are as follows:

[0026] Step 1, the raw material formula, the ratio range by weight is longan: red dates = 1:10.

[0027] Step 2, cooking: according to the ratio of raw materials, steam the longan and red dates in a steam cooking tank, then add tap water to the cooked longan and red dates, the amount of water added is 3 times the total mass of longan and red dates, stir and mix well, Then add the 1.5% Xiaoqu powder whose quality is the total mass of longan and red dates and stir evenly to make a thick mash; wherein, the steam pressure passed into the cooking tank is kept at 0.02MPa, and it is boiled at 100°C for 50min, and then heated at room temperature. Cooling was performed under pressure to 30°C, and tap water was added at a temperature of 30°C.

[0028] Step 3, enzymatic hydrolysis: add the thick mash prepared in the above step 2 into the saccharification enzymatic hyd...

Embodiment 2

[0038] The invention provides a kind of edible alcohol fermentation production process, concrete steps are as follows:

[0039] Step 1, the raw material formula, the proportioning range by weight is longan: red dates = 1:5.

[0040] Step 2, cooking: according to the ratio of raw materials, steam the longan and red dates in a steam cooking tank, then add tap water to the cooked longan and red dates, the amount of water added is 3 times the total mass of longan and red dates, stir and mix well, Then add the 1.5% Xiaoqu powder whose quality is the total mass of longan and red dates and stir evenly to make a thick mash; wherein, the steam pressure passed into the cooking tank is maintained at 0.02MPa, and it is boiled at 100°C for 55min, and then heated at room temperature. Cooling to 32°C was carried out under pressure, and tap water was added at a temperature of 35°C.

[0041] Step 3, enzymatic hydrolysis: add the thick mash prepared in the above step 2 into the saccharificatio...

Embodiment 3

[0051] The invention provides a kind of edible alcohol fermentation production process, concrete steps are as follows:

[0052] Step 1, the raw material formula, the proportioning range by weight is longan: red dates = 1:3.

[0053] Step 2, cooking: according to the ratio of raw materials, steam the longan and red dates in a steam cooking tank, then add tap water to the cooked longan and red dates, the amount of water added is 3 times the total mass of longan and red dates, stir and mix well, Then add the 1.5% Xiaoqu powder whose quality is the total mass of longan and red dates and stir evenly to make a thick mash; wherein, the steam pressure passed into the cooking tank is maintained at 0.02MPa, and it is boiled at 100°C for 60min, and then heated at room temperature. Cooling was carried out under pressure to 35°C, and tap water was added at a temperature of 40°C.

[0054] Step 3, enzymatic hydrolysis: add the thick mash prepared in the above step 2 into the saccharificatio...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com