Preparation method for large titanium-nickel alloy ingots

A titanium-nickel alloy, large-scale technology, which is applied in the field of preparation of large atomic ratio titanium-nickel alloy ingots, can solve problems affecting the success or failure of titanium-nickel alloy ingots, and achieve accuracy and uniformity, uniform alloy composition, and low impurity content Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

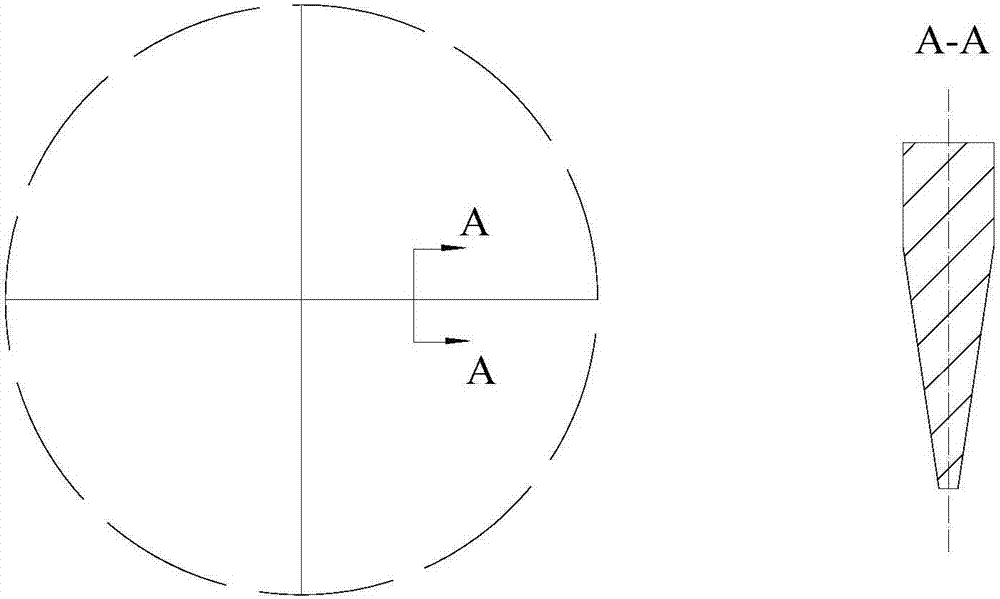

[0027] The preparation method specifically comprises the following steps:

[0028] Step 1. According to the ratio of titanium-nickel alloy and the number of auxiliary brackets to divide the mold cavity, use 3-12.7mm sponge titanium and square block electrolytic nickel as raw materials, according to the composition ratio of the titanium-nickel alloy to be prepared, carry out Weigh and batch the ingredients to obtain N parts of mixed raw materials, and the number of parts of mixed raw materials is the same as the number of blocks.

[0029] The raw materials for preparing titanium-nickel alloy are mainly sponge titanium and electrolytic nickel. The shapes of granular sponge titanium and large electrolytic nickel plates are quite different, and it is difficult to realize the cloth and pressing of electrode blocks. Therefore, the selection and preparation of raw materials is the primary key work. The square block electrolytic nickel is prepared by the following method: the electro...

Embodiment 1

[0035] Embodiment 1 The Φ460-800Kg ingot smelting method of TiNi50.8 (Ti-Ni50.8at%) alloy: the electrolytic nickel plate is rolled into a 6-8mm thick plate in advance, and punched into a square block with a side length of 8-10mm , cleaned and dried for later use. Sponge titanium uses small particles of 3-12.7mm. The grade of raw materials is 0 grade sponge titanium, Ni9999 electrolytic nickel.

[0036] According to the ratio of Ti-Ni50.8at% (Ti-Ni55.86wt%), press the Φ160-20Kg electrode block. The auxiliary bracket divides the mold cavity into four equal parts, each part is 5Kg. Weighing sponge titanium 2.207Kg, electrolytic nickel 2.793Kg. Mix by hand and pour into the griddle. Repeat the operation 4 times to complete the charging. After taking out the auxiliary bracket, uniformly vertically press it into a Φ160-20Kg electrode block. The electrode block is about 310mm high, and the selected equipment is a 2000T hydraulic press.

[0037] Weld 5 electrode blocks into a c...

Embodiment 2

[0041]Example 2 TiNiV (Ti-Ni50.8-V0.5at%) alloy Φ460-960Kg ingot smelting method: the electrolytic nickel plate is rolled into a 6-8mm thick plate in advance, and punched into a square with a side length of 8-10mm Block material, cleaned and dried for later use. Sponge titanium uses small particles of 3-12.7mm. The grade of raw materials is 0 grade sponge titanium, Ni9999 electrolytic nickel, AlV85 alloy.

[0042] According to the ratio of TiNiV (Ti-Ni55.85-V0.47wt%), press the Φ160-16Kg electrode block. The auxiliary bracket divides the mold cavity into four equal parts, each part is 4Kg. Weighing sponge titanium 1.744Kg, electrolytic nickel 2.234Kg, AlV85 alloy 0.022Kg. Sponge titanium and electrolytic nickel are artificially mixed and poured into the grid twice, and AlV85 alloy is placed in the middle. Repeat the operation 4 times to complete the charging. After the bracket is taken out, it is unified and vertically pressed into a Φ160-16Kg electrode block. The electr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com