Micro lens and sample table locking system based on atomic force probe

A technology of locking system and sample stage, which is applied in the field of microscope lens and sample stage locking system, can solve the problems of low precision, high cost, complex hardware, etc., and achieve the effect of high working precision, easy construction and simple system

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0031] The present invention will be described below in conjunction with the accompanying drawings, but the present invention is not limited thereto.

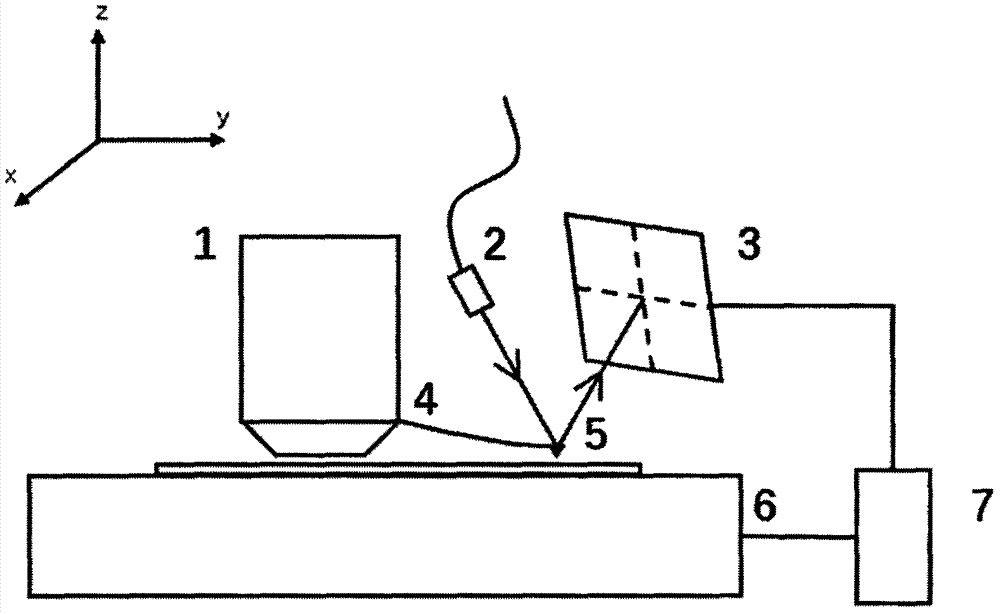

[0032] Such as figure 1 Shown is a schematic diagram of the atomic force probe-based microscope lens and sample stage locking system, including microscope lens 1, laser 2, four-quadrant detector 3, probe cantilever 4, atomic force probe 5, sample stage 6, and control unit 7 ;

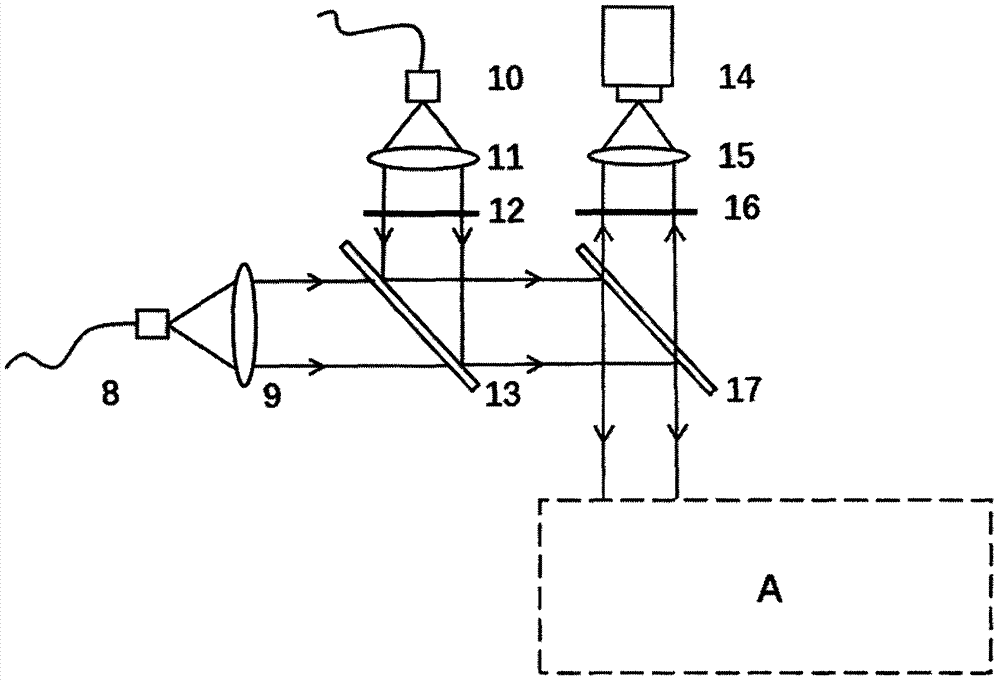

[0033] Such as figure 2 Shown is an optical path diagram of an embodiment of the device of the atomic force probe-based microscope lens and sample stage locking system of the present invention, which embodiment includes:

[0034] The device A of the microscope lens and sample stage locking system based on the atomic force probe, the excitation light source 8, the first lens 9, the loss light source 10, the second lens 11, the phase plate 12, the first dichromatic mirror 13, the detector 14, the second Three lens 15, optical filter 16, the second dich...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com