Intelligent belt transport communication control system

A communication control, intelligent belt technology, applied in general control systems, control/regulation systems, program control, etc., can solve problems such as large differences in belt configuration, poor control flexibility, and operational errors, and achieve complex software design. Fully protected, understandable and intuitive results

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

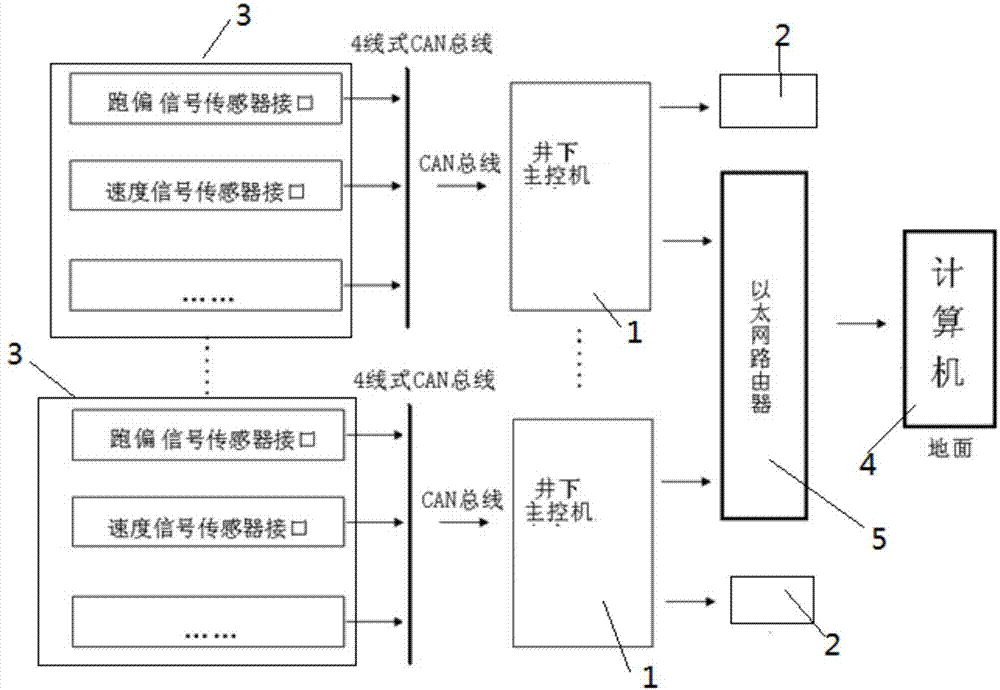

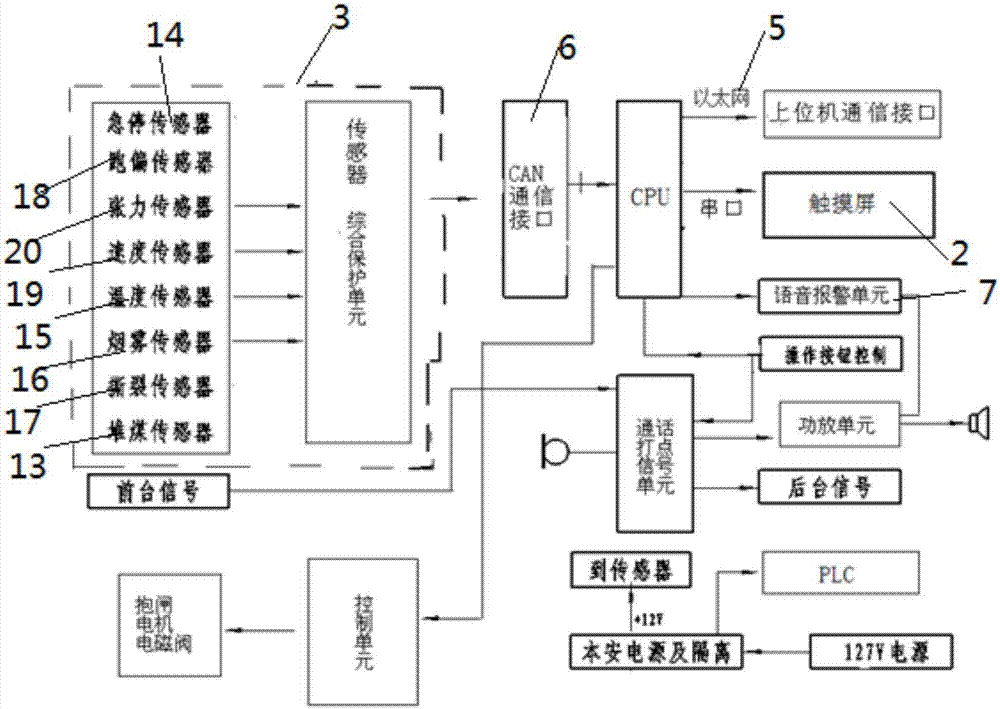

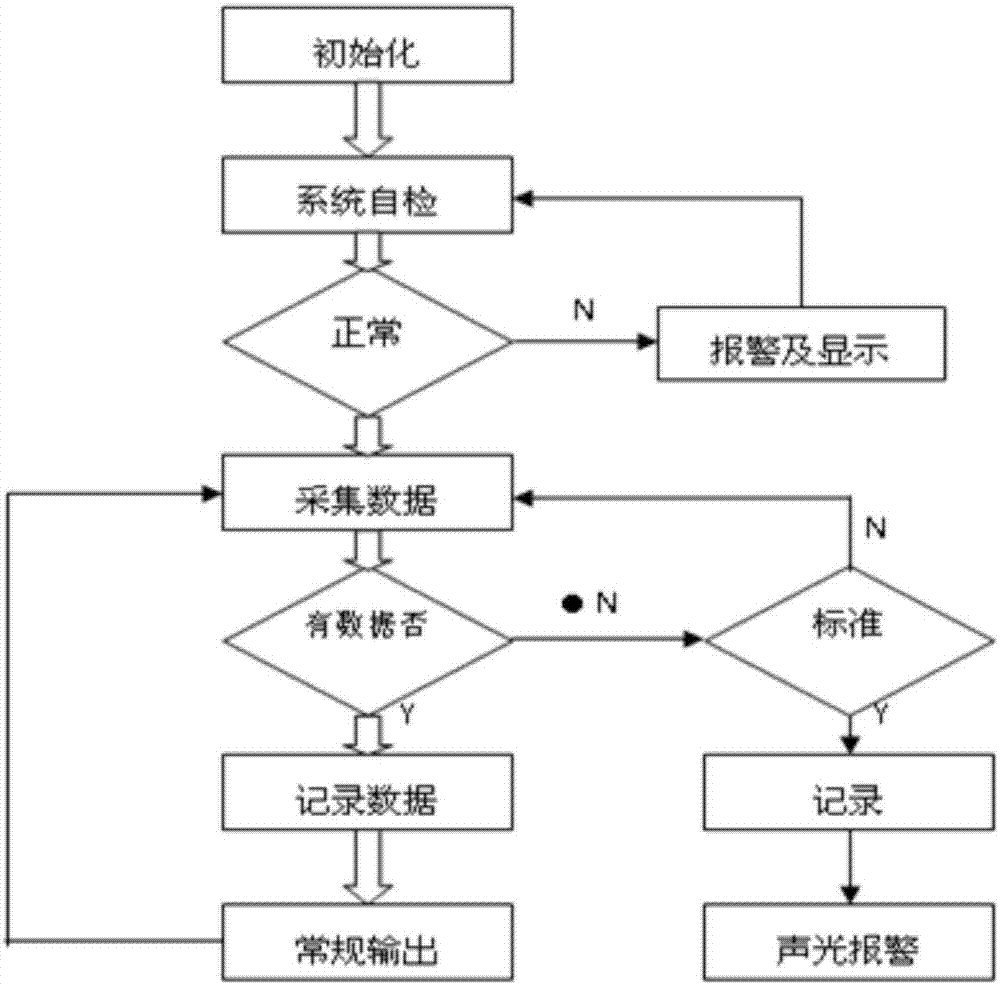

[0022] Such as figure 1 , 2 , 3, and 4, a communication control system for intelligent belt transportation includes an underground main control machine 1, an intrinsically safe color touch screen unit 2, a variety of belt protection module sensors 3 and a ground center computer 4, the various belts The protection module sensors 3 are respectively electrically connected to the downhole main control computer 1 through the bus interface, and the downhole main control computer 1 communicates with the ground center computer 4 and the intrinsically safe color touch screen unit 2 .

[0023] Described downhole master control machine 1 is externally connected by PLC PB-B-MODBUS bus bridge, Ethernet module 5, CAN bus interface circuit 6, voice alarm protection circuit 7, signal data display output circuit, a plurality of switching quantity control inputs, The output circuit, the touch screen RS485 interface and the memory interface are composed, the signal data display output circuit i...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com