Die taking and die bonding device and die bonding machine employing same

A technology of die bonding and driving device, which is applied in semiconductor/solid-state device manufacturing, electrical components, circuits, etc., and can solve the problems of chip voiding, uneven temperature control, and high energy consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach

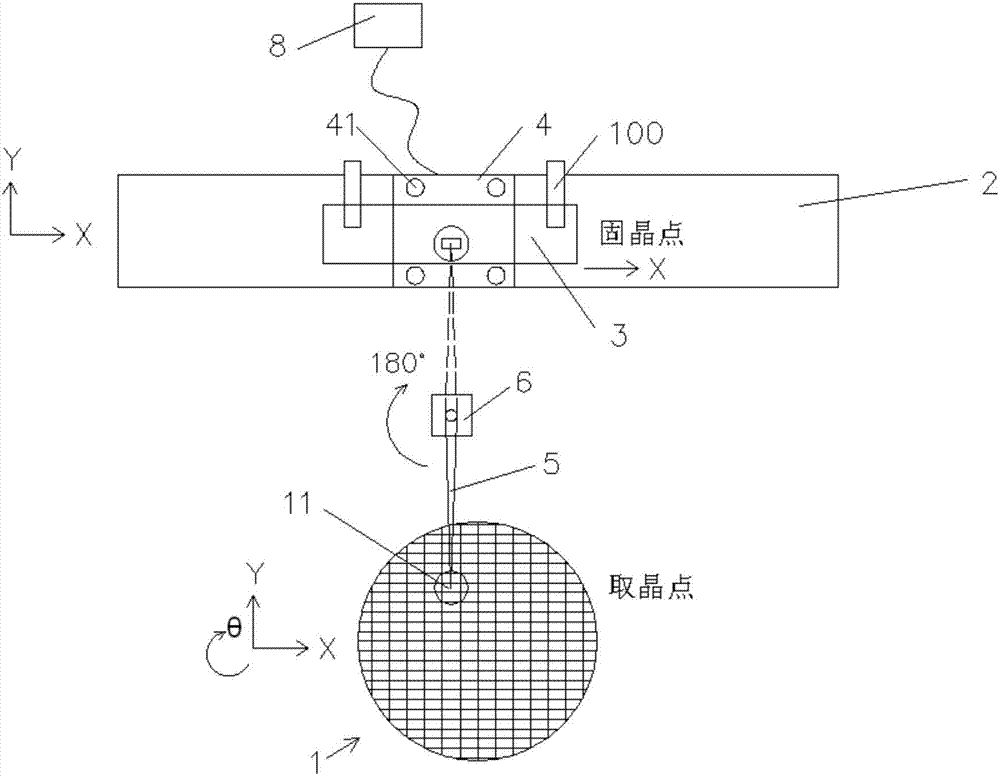

[0026] In order to achieve the purpose of the present invention, as shown in the figure, one embodiment of the present invention is: a crystal extraction and crystal bonding device, including:

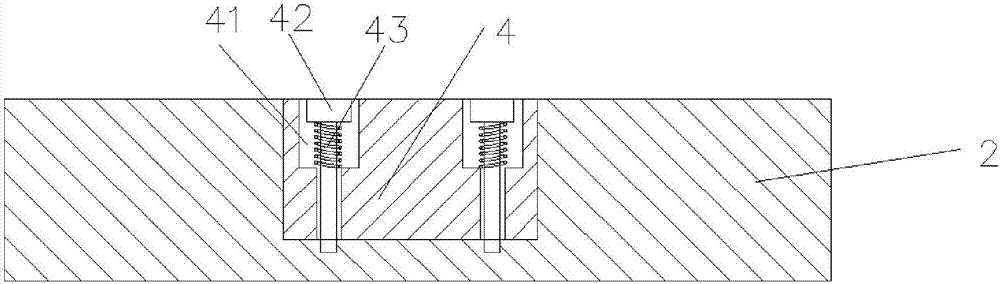

[0027] Solid crystal table 2, solid crystal table 2 moves along X, Y direction, and plane fixture seat 4 is embedded on solid crystal table 2, and plane fixture seat 4 is flush with solid crystal table 2, and plane fixture seat 4 is connected with Heating device 8;

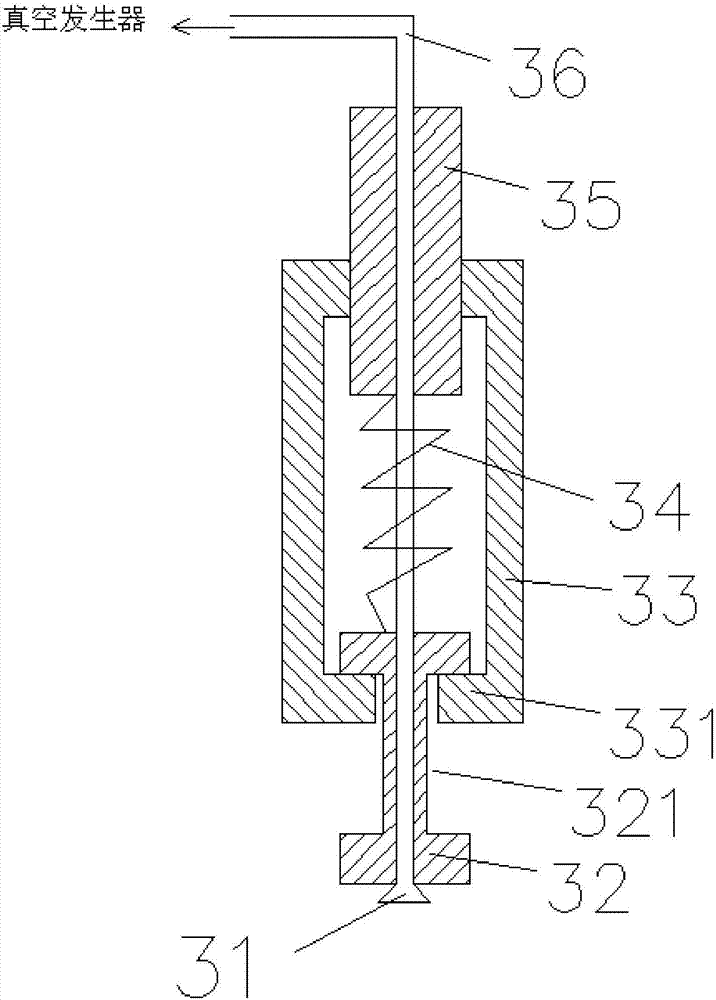

[0028] The rotating arm 5 is provided with a welding head that moves back and forth along the axis of rotation parallel to the rotating arm 5, and the welding head is used for crystal extraction and solid crystal;

[0029] Substrate 3. The substrate 3 is located above the die-bonding table 1 and moves in the X direction relative to the die-bonding table 1. The substrate 3 is fixed by the clamping jaws 100, and the stepping motor drives the clamping jaws to perform the feeding motion.

[0030] The first driving device 6, t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com