Photovoltaic power supply

A photovoltaic power supply and photovoltaic cell technology, applied in photovoltaic power generation, photovoltaic modules, electrical components, etc., can solve problems such as complex control algorithms, high sampling accuracy requirements, and large calculation loads, and achieve simple circuit structure, fast tracking speed, and easy Achieved effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0025] The present invention will be further described below with examples in conjunction with the drawings.

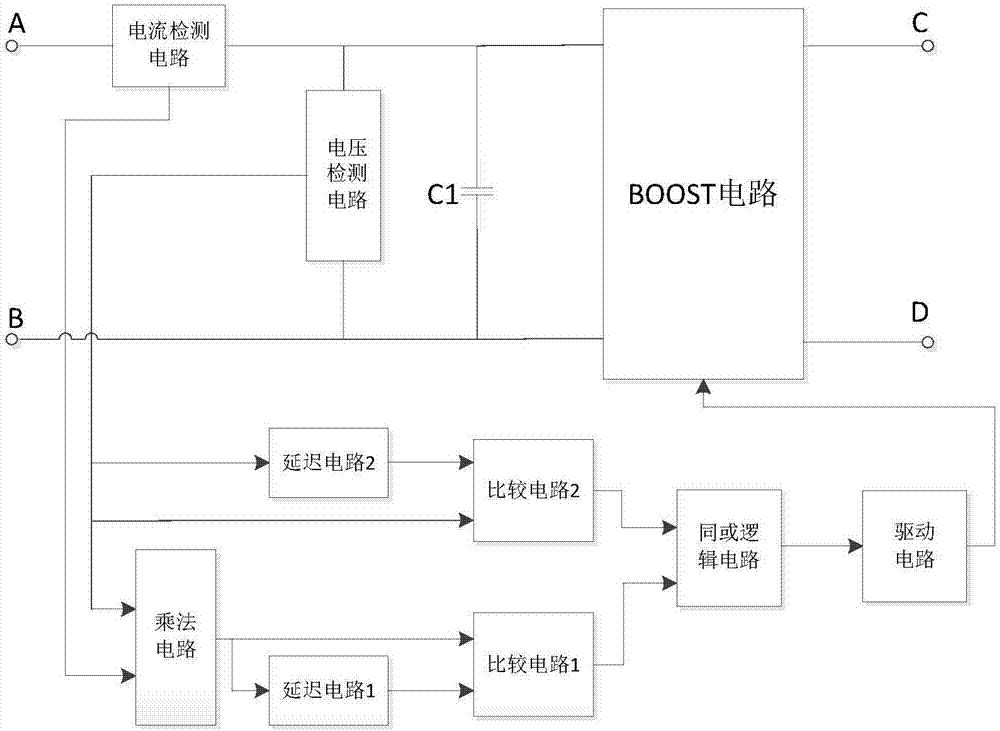

[0026] The photovoltaic power supply of the present invention is mainly composed of a power conversion circuit, a control circuit, etc., and specifically includes a Boost circuit, a capacitor C1, a current detection circuit, a voltage detection circuit, a multiplication circuit, a delay circuit 1, a delay circuit 2, a comparison circuit 1, a comparison circuit 2. XOR logic circuit and drive circuit.

[0027] The circuit structure diagram of the photovoltaic power supply proposed by the present invention is as follows figure 1 As shown, the connection relationship of the circuit is: circuit input connection points A and B are respectively connected to the positive and negative poles of the photovoltaic cell, that is, the output of the photovoltaic cell is connected to the input of the Boost circuit; the current detection circuit detects the output current of the photovoltai...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com