Ultra-thin water cooling plate and processing method thereof

A processing method and technology for water-cooled panels, which are applied in cooling/ventilation/heating transformation, electrical components, electrical equipment structural parts, etc. It is difficult to process the heat dissipation structure and other problems, so as to avoid unreliable welding, avoid dents, and reduce weight.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach 1

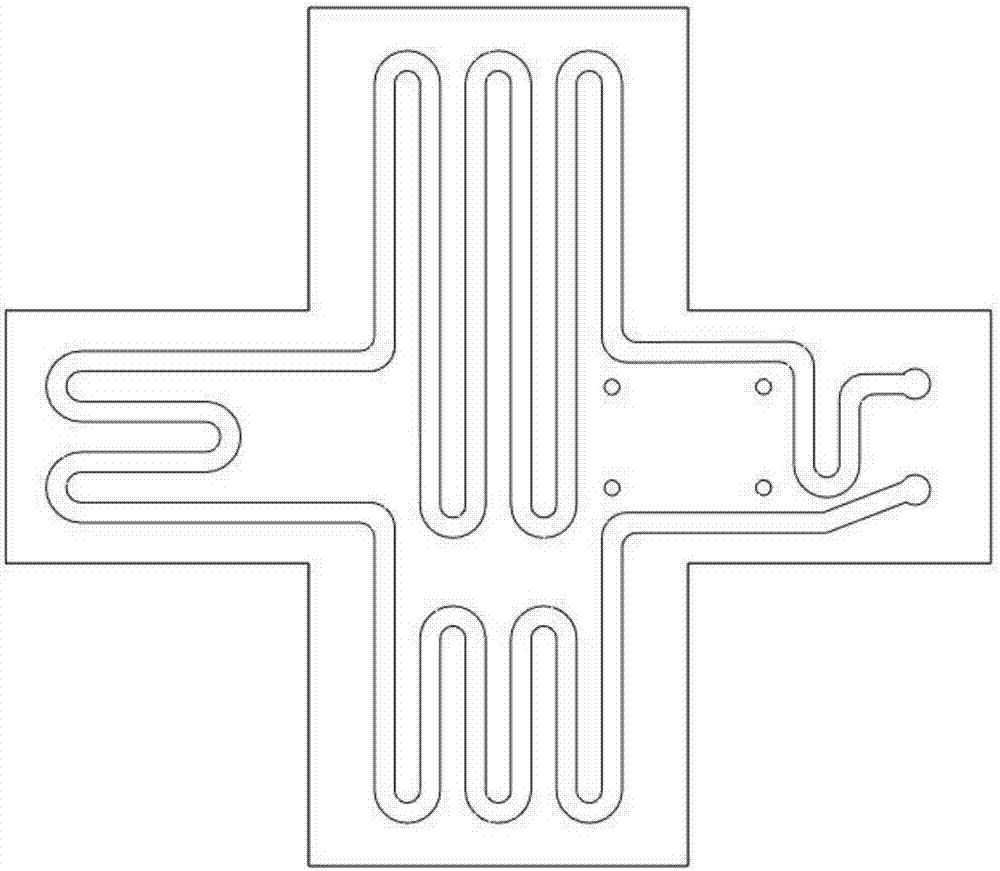

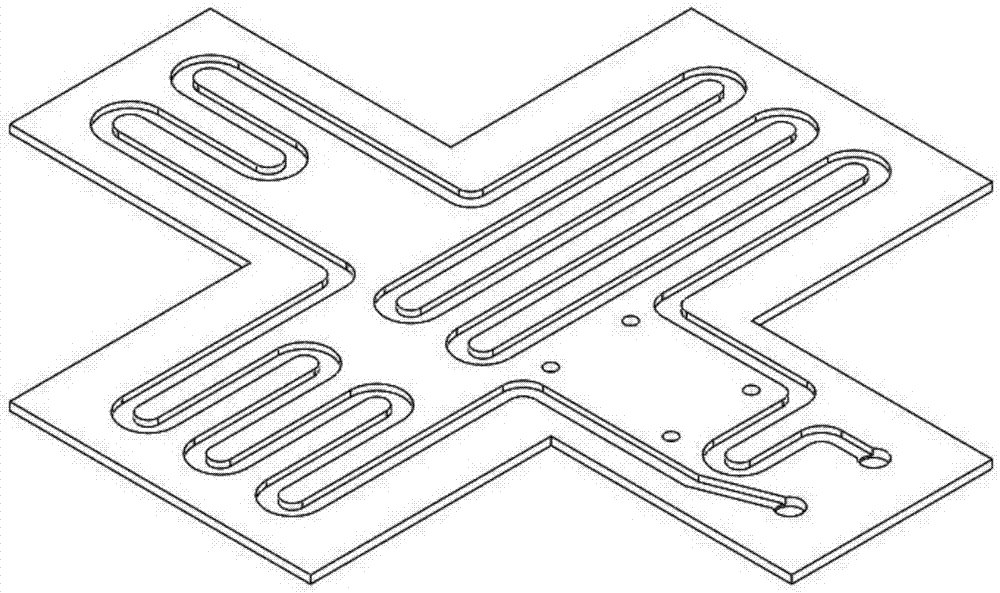

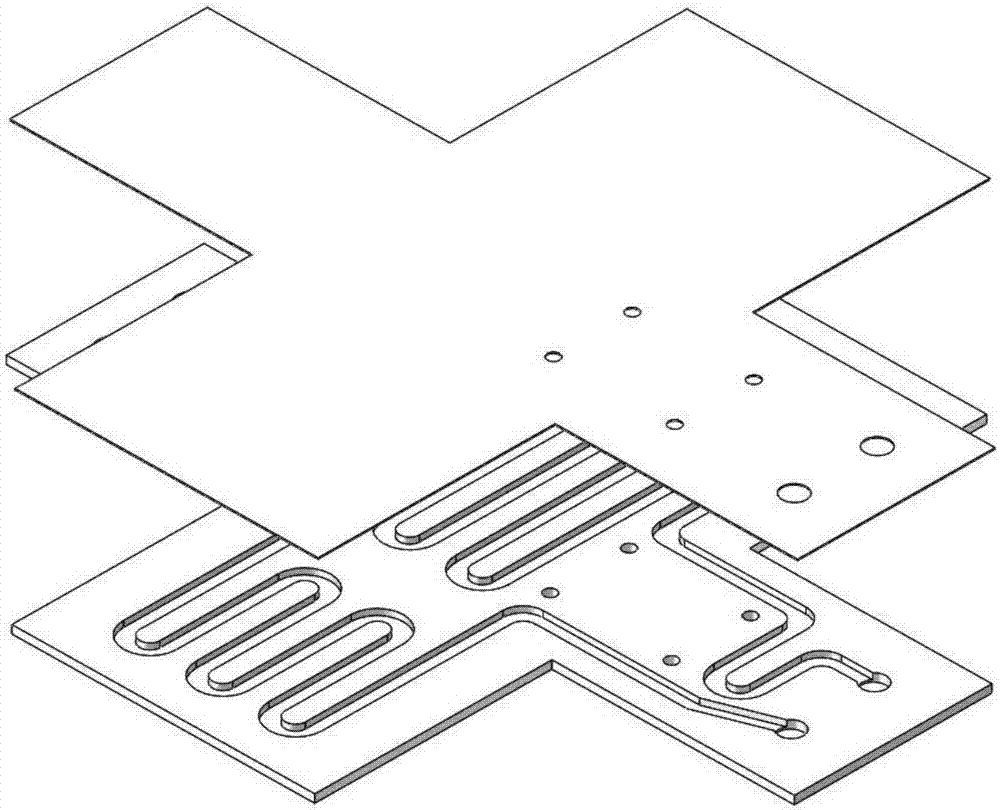

[0055] combine Figure 1-4 and 6 illustrate this embodiment, an ultra-thin water-cooled plate of this embodiment, the thickness of the water-cooled plate is 0.5mm-3.5mm, the water-cooled plate is stacked by two plates and fixedly connected by diffusion welding, wherein at least A water flow channel is etched on the side wall of one plate, and the water flow channel is located between the two plates, and any one of the two plates is provided with a water inlet corresponding to the water inlet end and the water outlet end of the water flow channel and outlet.

[0056] In this embodiment, a water flow channel is etched on the side wall of one plate, and the other plate is a flat plate, such as image 3 shown; it is also possible to etch the water flow channels on the side walls of the two plates, and then fasten the sides of the two plates with the water flow channels oppositely, as shown in Figure 4 shown.

[0057] The thickness of the water-cooled plate in this embodiment c...

Embodiment approach 2

[0075] combine Figure 5Describe this embodiment, an ultra-thin water-cooled plate of this embodiment, the thickness of the water-cooled plate is 0.5mm-3.5mm, the water-cooled plate is provided with a water flow channel, and the width of the water-flow channel perpendicular to the surface of the water-cooled plate is 50%-70% of the thickness of the water-cooled plate. The water-cooled plate is composed of three plates superimposed on each other and fixedly connected by diffusion welding. The middle plate is provided with a hollow water flow channel, and any one of the plates on both sides is provided with a connection with the water flow channel. The water inlet and the water outlet corresponding to the water inlet and the water outlet. like Figure 5 shown.

[0076] The hollow water flow channel in this embodiment can be formed by wire cutting, laser cutting or plasma cutting, among which wire cutting is better, because the wire cutting method has a higher dimensional accu...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com