Polyamide resin foam-molded article and method for producing polyamide resin foam-molded article

A foamed molding, polyamide-based technology, applied in the field of polyamide-based resin foamed moldings, to achieve the effect of excellent heat resistance and sound insulation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

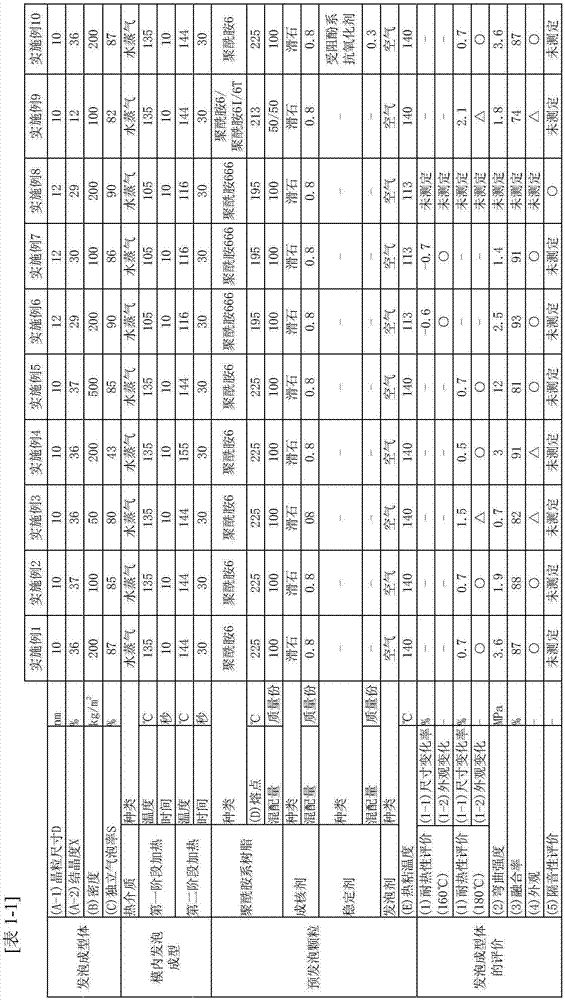

Embodiment 1

[0170] Using an extruder, 100 parts by mass of nylon 6 (trade name: UBENylon1022B, manufactured by Ube Industries, Ltd.) as a polyamide-based resin and 0.8 parts by mass of talc as a nucleating agent were melt-kneaded under heating conditions, After that, it is extruded in a strand form, water-cooled in a cold water tank, and cut to produce a pellet-shaped base resin.

[0171] The base resin was made to contain carbon dioxide gas as a foaming agent in accordance with the method described in the Examples of JP-A-2011-105879. And, the base resin containing carbon dioxide gas is heated, thereby foaming occurs, and a density of 300kg / m is obtained. 3 pre-expanded particles.

[0172] The obtained pre-expanded particles were enclosed in an autoclave, and compressed air was introduced for 1 hour until the pressure in the autoclave reached 0.5 MPa, and then the pressure was kept at 0.5 MPa for 24 hours, thereby pressurizing the pre-expanded particles deal with.

[0173] Fill the pr...

Embodiment 2

[0178] Obtain density 300kg / m similarly with embodiment 1 3 After the pre-expanded particles, set the following conditions in the pressure treatment: the obtained pre-expanded particles are sealed in an autoclave, and compressed air is introduced for 1 hour until the pressure in the autoclave reaches 0.3MPa, and then the The pressure was maintained at 0.3 MPa for 24 hours. And, before putting the pre-expanded particles after the pressure treatment into the mold, they were further heated at 230° C., thereby further foaming occurred, and the density was 150 kg / m 3 . Except for this point and the above conditions, it carried out similarly to Example 1, and obtained the foam molding.

[0179] Table 1 shows the evaluation results of the polyamide-based resin foam molded article of Example 2.

Embodiment 3

[0181] Obtain density 150kg / m similarly with embodiment 2 3After the pre-expanded particles, the following conditions are set: the obtained pre-expanded particles are sealed in an autoclave, and compressed air is introduced for 1 hour until the pressure in the autoclave reaches 0.15MPa, and then the pressure is maintained at 0.15MPa 24 hours. And, before putting the pre-expanded particles after the pressure treatment into the mold, they were further heated at 230° C., thereby further foaming occurred, and the density was 50 kg / m 3 . Except for this point and the above conditions, it carried out similarly to Example 1, and obtained the foam molding.

[0182] Table 1 shows the evaluation results of the polyamide-based resin foam molded article of Example 3.

PUM

| Property | Measurement | Unit |

|---|---|---|

| density | aaaaa | aaaaa |

| melting point | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com