Gas distributor and adsorption tower

A gas distributor and gas distribution technology, applied in gas treatment, removal of gas pollutants, selection of absorbent solid gas purification, etc., can solve problems such as poor adsorption effect and uneven gas distribution in the adsorbent bed , to achieve the effect of high efficiency, lower production cost and uniform gas distribution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

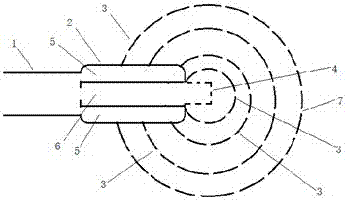

[0061] A gas distributor of an adsorption tower, such as attached figure 1 As shown, it includes a feed pipe 1, a pre-distributor 2, and a gas distribution pipe 3. One end of the pre-distributor 2 is connected to the feed pipe, and the other end is deep into the adsorption tower. The pre-distributor 2 includes an annular gap 5 and an intermediate gas outlet pipe 6. , the middle gas outlet pipe 6 has a circular hole near the diameter of the adsorption tower, the gas distribution pipe 3 is connected to the pre-distributor 2, and passes through the annular gap 5; the gas distribution pipe 3 contains a circular opening 7.

[0062] The gas distribution pipes 3 are annular and share the same center with the adsorption tower; the number of the gas distribution pipes 3 is 4, and the gas distribution pipes 3 are distributed equidistantly along the diameter of the adsorption tower.

Embodiment 2

[0064] A gas distributor of an adsorption tower, such as attached figure 1 As shown, it includes a feed pipe 1, a pre-distributor 2, and a gas distribution pipe 3. One end of the pre-distributor 2 is connected to the feed pipe, and the other end is deep into the adsorption tower. The pre-distributor 2 includes an annular gap 5 and an intermediate gas outlet pipe 6. , the middle gas outlet pipe 6 has a circular hole near the diameter of the adsorption tower, the gas distribution pipe 3 is connected to the pre-distributor 2, and passes through the annular gap 5; the gas distribution pipe 3 contains a circular opening 7.

[0065] The gas distribution pipes 3 are annular and share the same center with the adsorption tower; the number of the gas distribution pipes 3 is 4, and the gas distribution pipes 3 are distributed equidistantly along the diameter of the adsorption tower.

[0066] The gas distribution pipe 3 starts from connecting the two ends of the pre-distributor, and along...

Embodiment 3

[0069] as attached figure 1 As shown, a gas distributor of an adsorption tower includes a feed pipe 1, a pre-distributor 2, and a gas distribution pipe 3. One end of the pre-distributor 2 is connected to the feed pipe, and the other end penetrates into the interior of the adsorption tower. The pre-distributor 2 Including the annular gap 5 and the middle gas outlet pipe 6, the middle gas outlet pipe 6 has a circular hole close to the diameter of the adsorption tower, the gas distribution pipe 3 is connected to the pre-distributor 2, and passes through the annular gap 5; the gas distribution pipe 3 contains a circular hole. Opening 7.

[0070] The gas distribution pipes 3 are annular and share the same center with the adsorption tower; the number of the gas distribution pipes 3 is 4, and the gas distribution pipes 3 are distributed equidistantly along the diameter of the adsorption tower.

[0071]The gas distribution pipe 3 starts from connecting the two ends of the pre-distrib...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com