Method for producing transparent liquid marble and liquid marble and application

A technology of transparent liquid and liquid marbles, which is applied in the direction of granulating raw materials, chemical instruments and methods, chemical/physical/physicochemical reactors, etc., and can solve the problem of low transparency, low stability, and the surface of liquid marbles. Low particle density and other problems, to achieve high transparency, high stability, clear observation effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

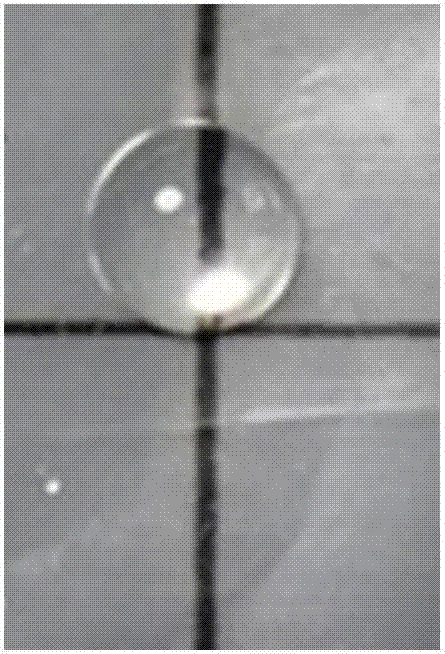

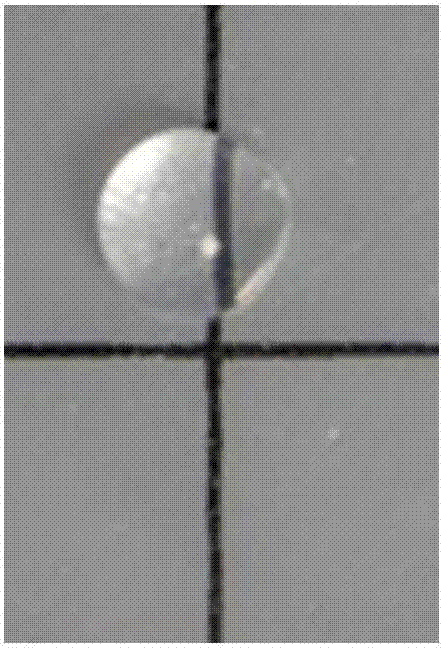

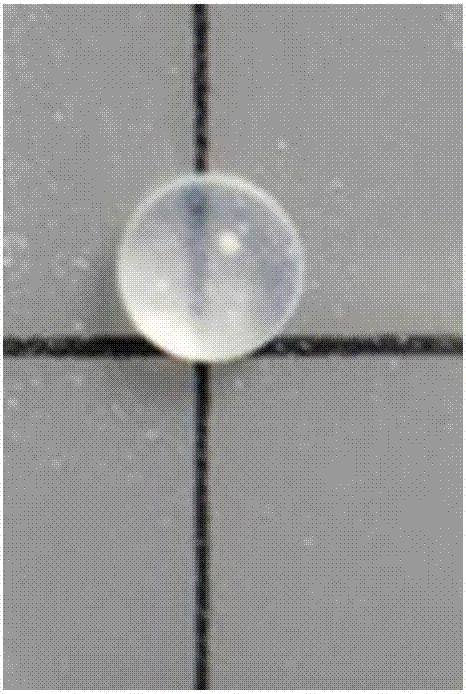

Image

Examples

Embodiment 1

[0040] A method for producing transparent liquid marbles, comprising the steps of:

[0041] Control the indoor temperature at 15°C and the indoor humidity above 50%, prepare SiO 2 Nanoparticles are used to make liquid marbles. The silicon dioxide used is the nanoparticle produced by the vapor phase deposition method modified by dimethyldichlorosilane, and the average particle size is at the nanometer level.

[0042] First cover the plane of the stationary vibrating table with a layer of plastic film to prevent pollution, and place a non-hydrophilic plastic container on the plane of the stationary electric vibrating table for operation. The diameter of the plastic container is at least 20mm.

[0043] A layer of silicon dioxide powder is spread on the bottom of the plastic container, and the powder needs to completely cover the surface.

[0044] Use a micropipette to drop a 10 microliter droplet onto the silica powder layer.

[0045] Turn on the electric vibration table, set t...

Embodiment 2

[0047] A method for producing transparent liquid marbles, comprising the steps of:

[0048] Control the indoor temperature at 30°C and the indoor humidity above 50%, prepare SiO 2 Nanoparticles are used to make liquid marbles. The silicon dioxide used is the nanoparticle produced by the vapor phase deposition method modified by dimethyldichlorosilane, and the average particle size is at the nanometer level.

[0049] First cover the plane of the stationary vibrating table with a layer of plastic film to prevent pollution, and place a non-hydrophilic plastic petri dish on the plane of the static electric vibrating table for operation. The diameter of the plastic petri dish is at least 20mm.

[0050] A layer of silica powder is spread on the bottom of the plastic petri dish, and the powder needs to completely cover the surface.

[0051] Use a micropipette to drop 1000 microliters of a droplet onto the silica powder layer.

[0052] Turn on the electric vibration table, set the p...

Embodiment 3

[0054] A method for producing transparent liquid marbles, comprising the steps of:

[0055] Control the indoor temperature at 25°C and the indoor humidity above 50%, prepare SiO 2 Nanoparticles are used to make liquid marbles. The silicon dioxide used is the nanoparticle produced by the vapor phase deposition method modified by dimethyldichlorosilane, and the average particle size is at the nanometer level.

[0056] First cover the plane of the stationary vibrating table with a layer of plastic film to prevent pollution, and place a non-hydrophilic plastic petri dish on the plane of the static electric vibrating table for operation. The diameter of the plastic petri dish is at least 20mm.

[0057] A layer of silica powder is spread on the bottom of the plastic petri dish, and the powder needs to completely cover the surface.

[0058] Use a micropipette to drop 500 microliters of a droplet onto the silica powder layer.

[0059] Turn on the electric vibration table, set the pa...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

| Diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com