Centrifuge for processing architectural paint catalysts

A technology for architectural coatings and centrifuges, used in centrifuges, coatings, etc., can solve the problems of short service life, poor corrosion resistance of drums, and low structural stability, and achieve compact structure, stable operation, and light weight. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

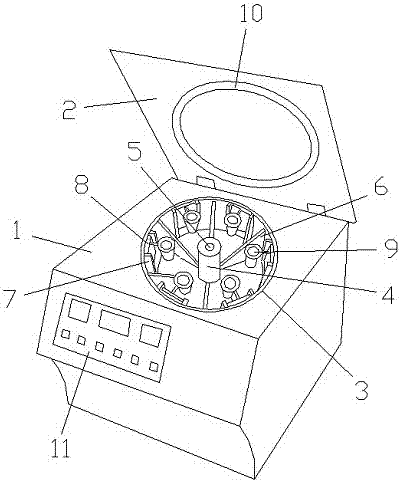

[0025] Such as figure 1 Shown, a kind of centrifuge for architectural paint catalyst processing comprises centrifuge body 1, end cover 2, drum 3 and axle sleeve 4, and described end cover 2 is arranged on the centrifuge body 1, and described end cover 2 and centrifuge The machine body 1 is hinged, the drum 3 is installed in the centrifuge body 1, the shaft sleeve 4 is arranged in the middle of the drum 3, the shaft sleeve 4 is provided with a rotating shaft 5, and the rotating shaft 5 is rotationally connected with the centrifuge body 1 , the drum 3 is provided with a reinforcing plate 6 and a card slot 7, the reinforcing plate 6 is fixedly connected with the drum 3, a slide 8 is arranged in the card slot 7, and the slide 8 is movably connected with the card slot 7 , one end of the slide 8 is provided with a test tube rack 9 , and the test tube rack 9 is fixedly connected with the slide 8 .

[0026] The reinforcing plate 6 is arranged in a triangular shape.

[0027] A sealin...

Embodiment 2

[0039] Such as figure 1 Shown, a kind of centrifuge for architectural paint catalyst processing comprises centrifuge body 1, end cover 2, drum 3 and axle sleeve 4, and described end cover 2 is arranged on the centrifuge body 1, and described end cover 2 and centrifuge The machine body 1 is hinged, the drum 3 is installed in the centrifuge body 1, the shaft sleeve 4 is arranged in the middle of the drum 3, the shaft sleeve 4 is provided with a rotating shaft 5, and the rotating shaft 5 is rotationally connected with the centrifuge body 1 , the drum 3 is provided with a reinforcing plate 6 and a card slot 7, the reinforcing plate 6 is fixedly connected with the drum 3, a slide 8 is arranged in the card slot 7, and the slide 8 is movably connected with the card slot 7 , one end of the slide 8 is provided with a test tube rack 9 , and the test tube rack 9 is fixedly connected with the slide 8 .

[0040] The reinforcing plate 6 is arranged in a triangular shape.

[0041] A sealin...

Embodiment 3

[0053] like figure 1 Shown, a kind of centrifuge for architectural paint catalyst processing comprises centrifuge body 1, end cover 2, drum 3 and axle sleeve 4, and described end cover 2 is arranged on the centrifuge body 1, and described end cover 2 and centrifuge The machine body 1 is hinged, the drum 3 is installed in the centrifuge body 1, the shaft sleeve 4 is arranged in the middle of the drum 3, the shaft sleeve 4 is provided with a rotating shaft 5, and the rotating shaft 5 is rotationally connected with the centrifuge body 1 , the drum 3 is provided with a reinforcing plate 6 and a card slot 7, the reinforcing plate 6 is fixedly connected with the drum 3, a slide 8 is arranged in the card slot 7, and the slide 8 is movably connected with the card slot 7 , one end of the slide 8 is provided with a test tube rack 9 , and the test tube rack 9 is fixedly connected with the slide 8 .

[0054] The reinforcing plate 6 is arranged in a triangular shape.

[0055] A sealing r...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com