Device and method for measuring pour point of crude oil and petroleum products under different pressures

A technology for petroleum products and measuring devices, applied in the investigation stage/state change and other directions, can solve the problems of difficulty in measuring the pour point of heavy oil and heavy oil, limited test pressure, and limited application range.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

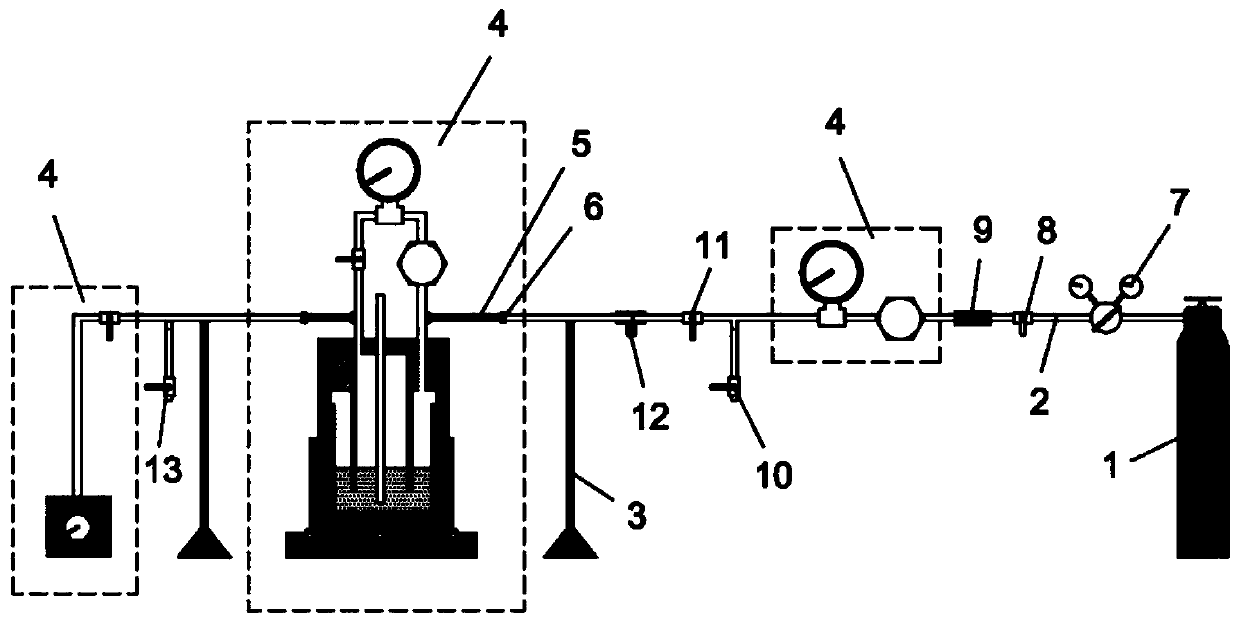

[0071] Such as Figure 1-5 As shown, according to the measuring device of the pour point of crude oil and petroleum products under different pressures according to the present invention, it comprises a nitrogen cylinder 1, a pipeline 2, and two brackets 3, and the pipeline 2 is connected with the nitrogen cylinder 1, and the bracket 3 Support the pipeline 2; the measuring device also includes a double-chamber pressure system 4, the double-chamber pressure system 4 is arranged between two supports 3, and high-pressure hoses 5 are respectively arranged on both sides of the double-chamber pressure system 4, The high-pressure hose 5 is connected to the pipeline 2 through a rotary joint 6 . The pipeline 2 is equipped with a pressure coarse regulator 7, a valve III8, a nitrogen filter 9, a pressure relief valve I10, a valve IV11, a safety valve 12, and a pressure relief valve II13.

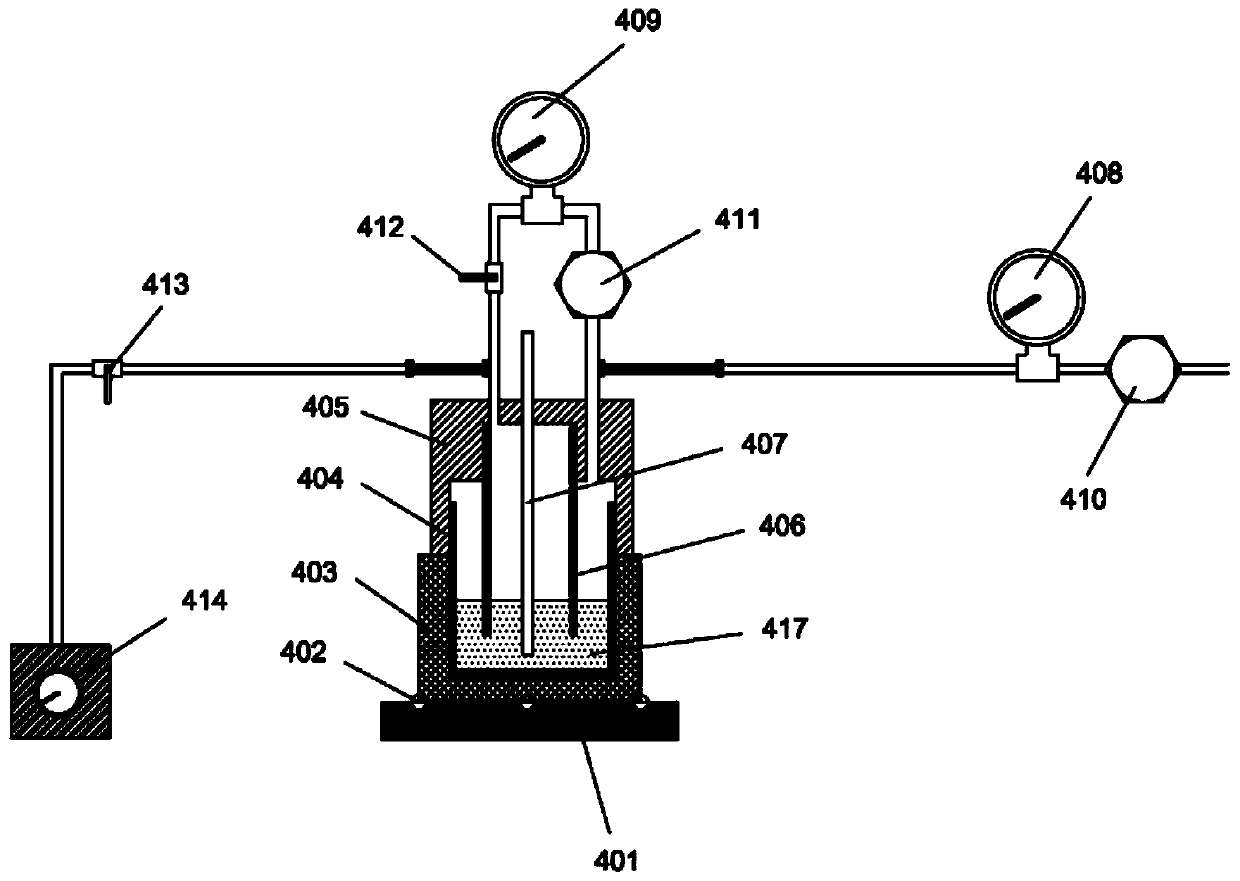

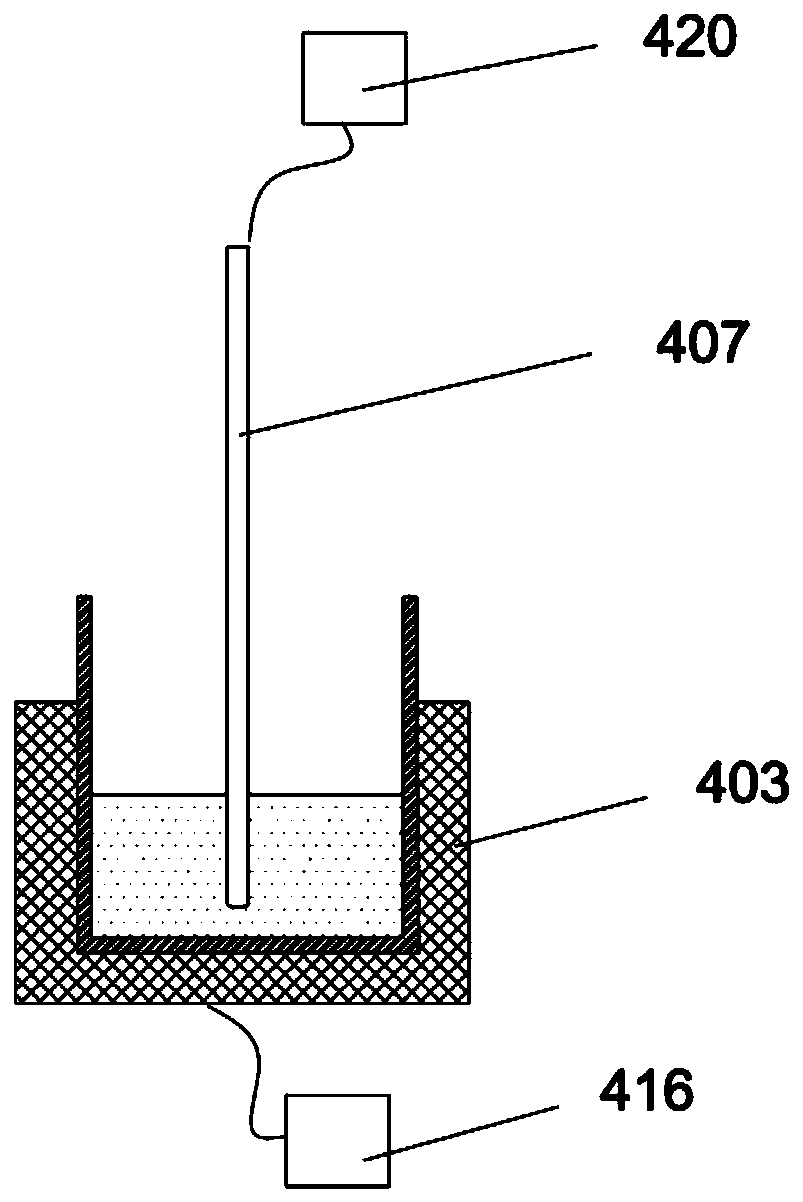

[0072] The double-chamber pressure system 4 includes a workbench 401, a rotary hinge 402, a tempera...

Embodiment 2

[0084] According to an embodiment of the automatic pneumatic measurement method of the pour point of crude oil and petroleum products under different pressures, the measuring device in Embodiment 1 is adopted, which comprises the following steps in sequence:

[0085] Step 1: Connect the measuring device, adjust the temperature regulator to a vertical state; open the test cylinder cover, and put the preheated crude oil or petroleum products into the test cylinder to the position of the liquid level scale line;

[0086] Step 2: Close the pressure relief valve Ⅰ, open the pressure relief valve Ⅱ, pressure trimmer Ⅰ, pressure trimmer Ⅱ and all valves installed on the pipeline; open the nitrogen cylinder, adjust the pressure coarse regulator to control the pressure value not greater than 2 atmospheres , Displace the air in the device, the displacement time is 5min; close the pressure relief valve II, observe the pressure readings of the pressure indicator gauge I and the pressure in...

Embodiment 3

[0107] According to an embodiment of the oblique method for measuring the pour point of crude oil and petroleum products under different pressures according to the present invention, the measuring device in Embodiment 1 is adopted, which comprises the following steps in sequence:

[0108] Step 1: Connect the measuring device, adjust the temperature regulator to a vertical state; open the test cylinder cover, and put the preheated crude oil or petroleum products into the test cylinder to the position of the liquid level scale line;

[0109] Step 2: Close the pressure relief valve Ⅰ, open the pressure relief valve Ⅱ, pressure trimmer Ⅰ, pressure trimmer Ⅱ and all valves installed on the pipeline; open the nitrogen cylinder, adjust the pressure coarse regulator to control the pressure value not greater than 2 atmospheres , Displace the air in the device, the displacement time is 5min; close the pressure relief valve II, observe the pressure readings of the pressure indicator gauge...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com