Nano-fiber heating plate

A technology of nanofibers and nanoceramic fibers, which is applied in the direction of electric heating devices, ohmic resistance heating, heating element materials, etc., can solve the problems of low heat exchange efficiency, low electrothermal conversion rate, high cost, etc., and achieve good heat resistance and mechanical properties , High electrothermal conversion rate, good protective effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

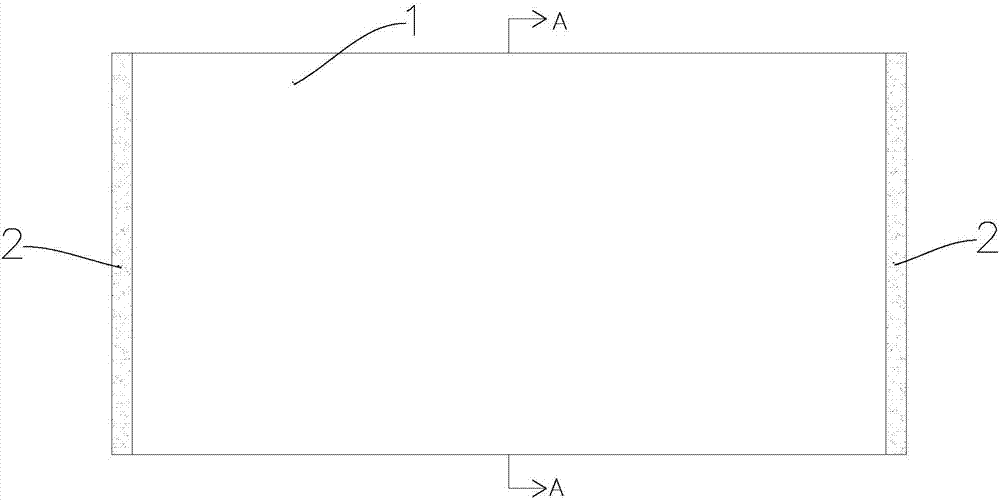

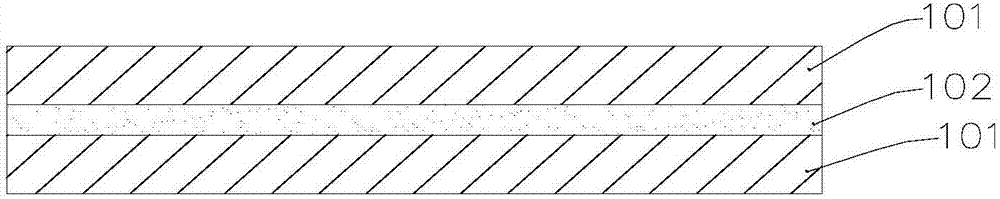

[0021] A nanofiber heating plate, which includes a heating plate body 1, the opposite sides of the heating plate body 1 are respectively fixedly connected with metal electrode sheets 2 for connecting with an external power supply, and the heating plate body is composed of upper and lower layers The insulating and wear-resistant layer 101 is composed of the nanofiber heating film layer 102 sandwiched in the middle, and the two sides of the nanofiber heating film layer 102 are respectively in electrical contact with the metal electrode sheet.

[0022] Specifically, the heating plate body is rectangular, the metal electrode is a copper sheet and its length is equal to the length of the wide side of the rectangular heating plate body, each wide side is electrically connected to a copper sheet, and the copper sheet is connected to the nanofiber heating film in the heating plate body The entire side of the layer located at the wide side is electrically contacted; the heating film lay...

Embodiment 2

[0024] A nanofiber heating plate, which includes a heating plate body 1, the opposite sides of the heating plate body 1 are respectively fixedly connected with metal electrode sheets 2 for connecting with an external power supply, and the heating plate body is composed of upper and lower layers The insulating and wear-resistant layer 101 is composed of the nanofiber heating film layer 102 sandwiched in the middle, and the two sides of the nanofiber heating film layer 102 are respectively in electrical contact with the metal electrode sheet.

[0025] Specifically, the heating plate body is square, and the metal electrodes are copper sheets whose length is equal to the side length of the square heating plate body. The corresponding entire sides of the nanofiber heating film layer in the board body are electrically contacted; the heating film layer is fully mixed with virgin wood pulp and nano ceramic fiber according to the weight ratio of 70:30, and then rolled on the insulating ...

Embodiment 3

[0027] A nanofiber heating plate, which includes a heating plate body 1, the opposite sides of the heating plate body 1 are respectively fixedly connected with metal electrode sheets 2 for connecting with an external power supply, and the heating plate body is composed of upper and lower layers The insulating and wear-resistant layer 101 is composed of the nanofiber heating film layer 102 sandwiched in the middle, and the two sides of the nanofiber heating film layer 102 are respectively in electrical contact with the metal electrode sheet.

[0028] Specifically, the heating plate body is rectangular, the metal electrode is a copper sheet and its length is equal to the length of the wide side of the rectangular heating plate body, each wide side is electrically connected to a copper sheet, and the copper sheet is connected to the nanofiber heating film in the heating plate body The entire side of the layer close to the wide side is electrically contacted; the heating film layer...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com