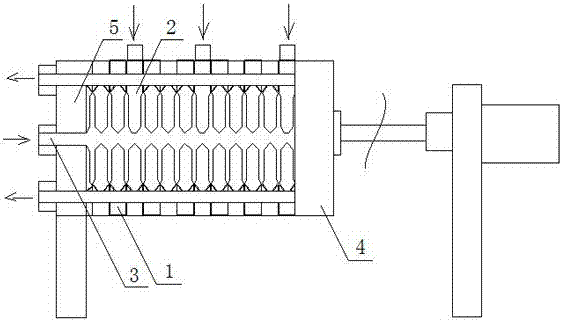

Plate-and-frame filter press in novel discharging manner

A plate and frame filter press, a new type of technology, applied in the direction of filtration and separation, separation methods, chemical instruments and methods, etc., can solve the problems of high labor intensity, hardened residue, unclean filter cake removal, etc., to achieve no environmental pollution, The effect of loose bonding and convenient transportation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0014] When the filter press is working, due to the action of the hydraulic cylinder, all the filter plates are pressed between the movable head plate and the fixed tail plate, so that a filter chamber is formed between adjacent filter plates, and the surrounding is sealed, and the slurry is driven by the thrust. The feeding hole of the plate is fed with a certain pressure. After all the filter chambers are filled with slurry, the filter press process starts. The slurry is separated from the solid and liquid by the pressure of the feeding pump, and the solid particles remain in the filter chamber due to the blocking of the filter cloth. , The filtrate is discharged through the filter cloth along the drainage ditch on the filter plate. After a period of time, the filtrate no longer flows out, and the dehydration process is completed. At this time, the feeding can be stopped, and the head plate can be adjusted by the hydraulic control system to return to the original position. Th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com