Treatment system suitable for kitchen waste

A processing system and kitchen waste technology, applied in the direction of solid waste removal, etc., can solve the problem that large bones and other objects are not easy to be disposed of, achieve a wide range of social and economic value, improve the effect, and avoid the effect of polluting the environment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

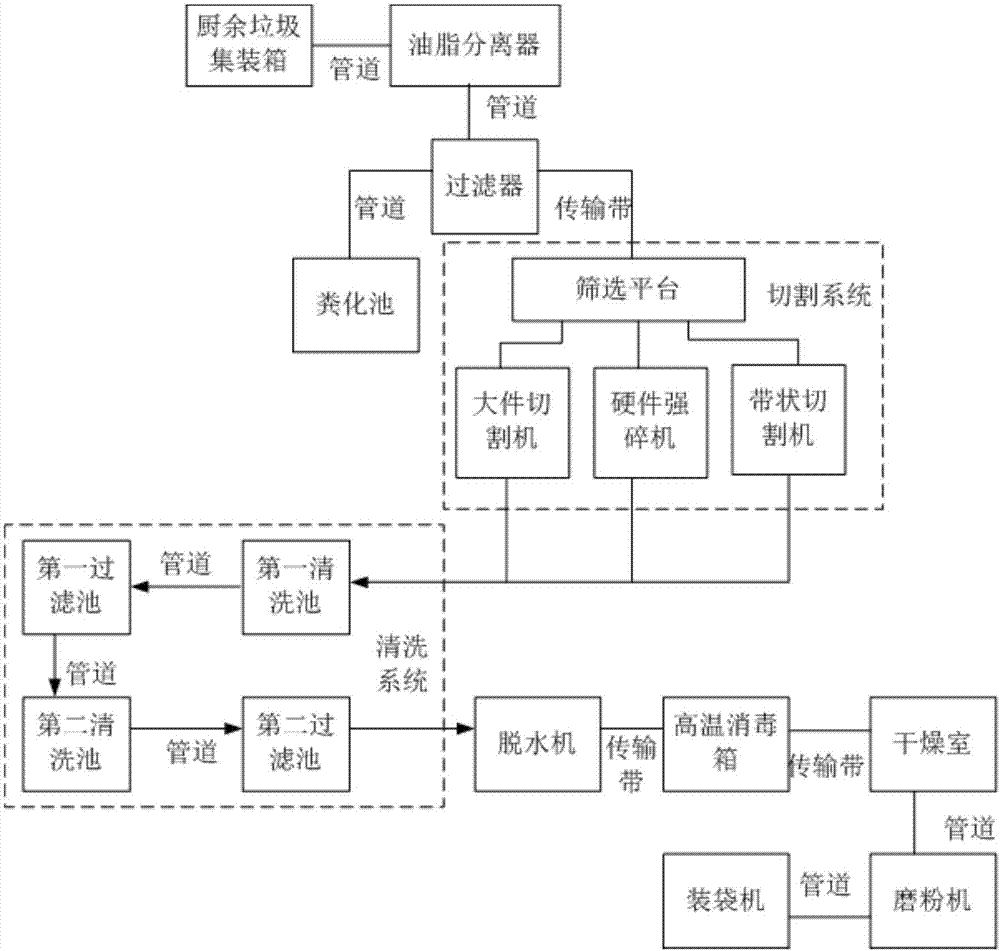

[0018] Such as figure 1 As shown, the present invention is applicable to the treatment system of kitchen waste, including a kitchen waste container, a grease separator, a filter, and a septic tank connected sequentially through pipelines, and also includes a cutting system connected sequentially with the filter through a conveyor belt, The cleaning system, the dehydrator, the high-temperature disinfection box, and the drying room also include a pulverizer and a bagging machine connected to the drying room through pipelines in sequence, wherein: the food waste container transports the food waste mixture to the grease separator; The grease separator receives the food waste mixture conveyed by the kitchen waste container, separates the grease, and conveys the deoiled mixture to the filter; the filter receives the deoiled mixture conveyed by the grease separator, conveys the liquid to the septic tank, and simultaneously conveys the solid mixture to the cutting system; the septic t...

Embodiment 2

[0020] Such as figure 1 As shown, the present invention is applicable to the processing system of kitchen waste. On the basis of Example 1, the cutting system includes a screening platform, which receives the solid mixture delivered by the filter, and the three output ports of the screening platform are respectively connected to The bulk cutter, hardware strong shredder, and ribbon cutter, the outputs of the bulk cutter, hardware strong shredder, and ribbon cutter are all connected to the cleaning system. The function of the screening platform is to divide kitchen waste into different types according to the difficulty of cutting, and then use targeted equipment for processing, and send large-volume objects in the waste, such as large pieces of wood, vegetable roots, branches, etc. Go to the large cutting machine to cut into small pieces; use the hardware powerful crusher to crush the large bones and corpses to form pieces or soft materials that can be processed. The strip cutt...

Embodiment 3

[0022] Such as figure 1As shown, the present invention is applicable to the treatment system of kitchen waste. On the basis of Example 1, the cleaning system includes a first cleaning tank, a first filtering tank, a second cleaning tank, and a second filtering tank. A cleaning tank, a first filtering tank, a second cleaning tank, and a second filtering tank are sequentially connected through pipelines along the direction that the cutting system points to the dehydrator. Both the first cleaning tank and the second cleaning tank are equipped with mixing agitators. The kitchen waste mixture is cleaned and filtered at least twice through the first cleaning tank, the first filter tank, the second cleaning tank, and the second filter tank to remove most of the salt and reduce the sodium ions and chloride ions of the kitchen waste mixture Concentration, improve the above problems, improve the quality of fertilizer powder.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com