Tandem vector thrust full-drive aircraft and its design method

An all-drive, aircraft technology, applied in the aerospace field, can solve problems such as large disturbance torque on the wing surface, uncontrollable attitude deflection of the aircraft, and uncontrollable attitude

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

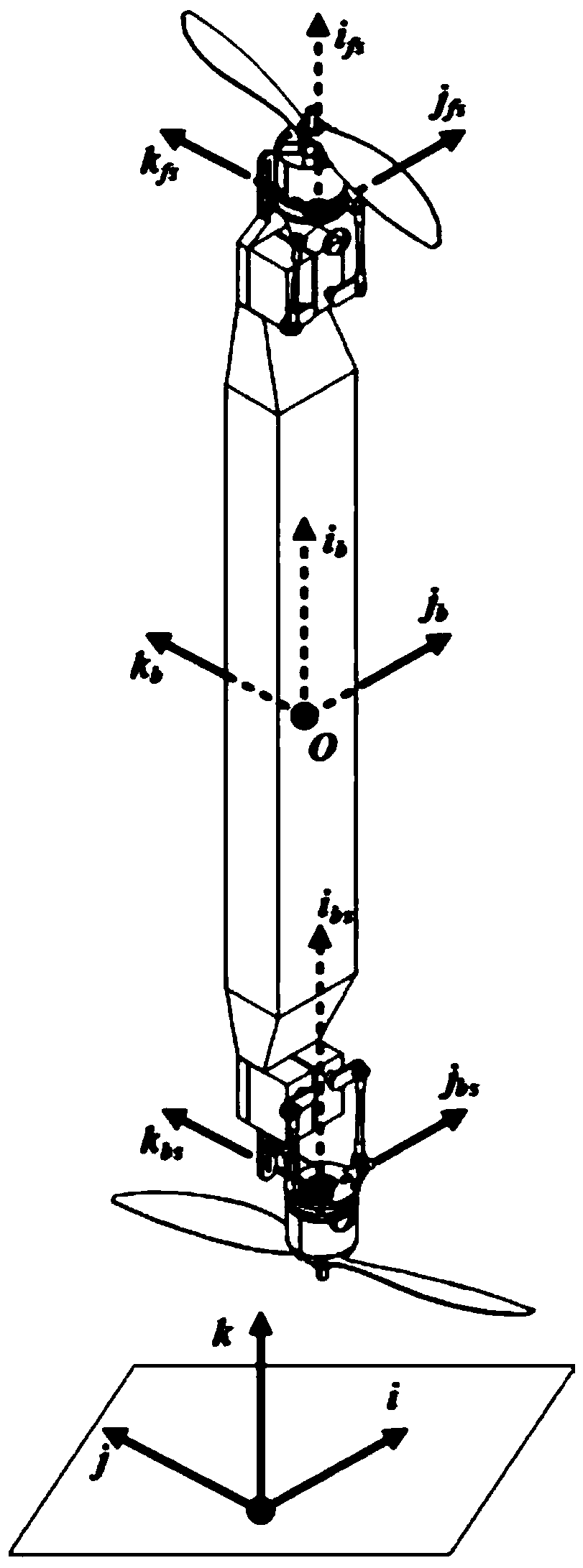

[0092] Specific implementation mode one: as Figure 1-Figure 9 As shown, this embodiment describes a tandem vector thrust full-drive aircraft, which is characterized in that: its composition includes a body 1, two electric thrust systems 3, two vector actuators 2, four steering gears 4 and two a connecting mechanism 5; the two electric thrust systems 3 are respectively a front electric thrust system and a rear electric thrust system, and the two vector actuators 2 are respectively a front vector actuator and a rear vector actuator, The four steering gears 4 are respectively two front steering gears and two rear steering gears, and the two connecting mechanisms 5 are respectively a front connecting mechanism and a rear connecting mechanism;

[0093] The front vector actuating mechanism is respectively connected with the front connecting mechanism and the front electric thrust system to form a front thrust vector actuating mechanism, and the front thrust vector actuating mechani...

specific Embodiment approach 2

[0096] Specific implementation mode two: as Figure 1-Figure 9 As shown, this embodiment is a further description of Embodiment 1. Each of the vector actuators 2 includes a phase limiter 6, a motor mounting base 7 and two connecting rods 8; the phase limiter 6 is connected with the corresponding connecting mechanism 5, the bottom of the motor of each electric thrust system 3 is fixed on the motor mount 7, one end of the two connecting rods 8 is connected with the motor mount 7, and the two connecting rods 8 and the other end is connected with the corresponding connecting mechanism 5.

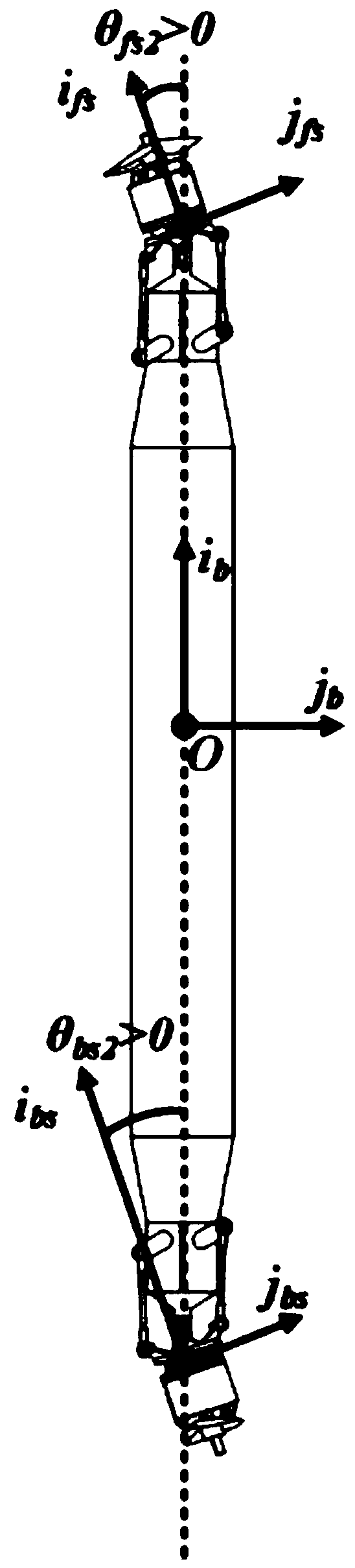

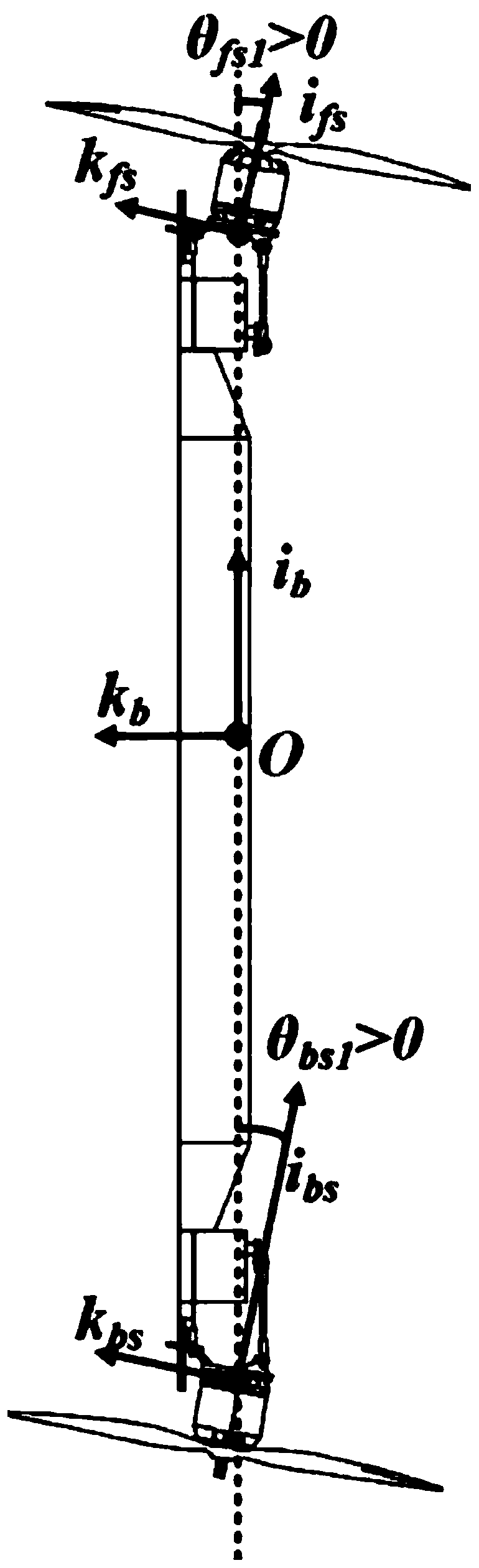

[0097] The connecting rod 8 is used to control the direction of the electric thrust vector, the phase limiter 6 is used to ensure that the motor mount 7 does not rotate; the motor mount 7 is used to connect with the electric thrust system 3 . The motor mount 7 of the vector actuator 2 is controlled by the connecting rod 8, and can form an angle with the body 1: θ 1 with theta 2 , θ 1 is the ...

specific Embodiment approach 3

[0098] Specific implementation mode three: as Figure 9 As shown, this embodiment is a further description of the second specific embodiment. The two front steering gears are connected to the two connecting rods 8 of the front vector actuator, and the two rear steering gears are connected to the rear vector The two connecting rods 8 of the actuating mechanism are connected.

[0099] The steering gear 4 is the executive mechanism that controls the vector actuator 2, and the control of the thrust vector can be realized by connecting the connecting rod 8 of the vector actuator 2, such as Figure 8 with Figure 9 shown.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com