Epoxy resin composition, preparation method thereof and neutron shielding material preparation method

A technology of epoxy resin and composition, which is applied in shielding, nuclear engineering, reactors, etc., can solve the problems of poor heat resistance and anti-aging performance, and achieve the goal of improving shielding performance, improving shielding ability, and enhancing neutron shielding performance Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0062] The present invention also proposes a preparation method of the epoxy resin composition, comprising the following steps:

[0063] Mixing hydrogenated epoxy resin, heat-resistant epoxy resin, boron compound and density increasing agent to obtain a first mixture;

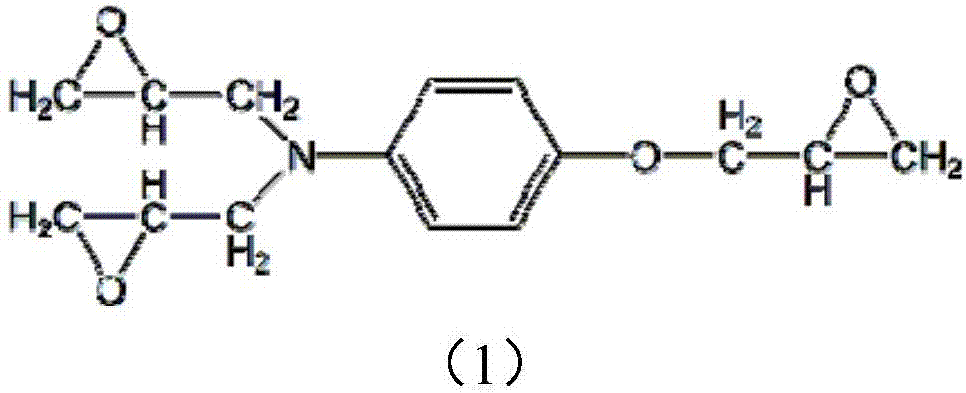

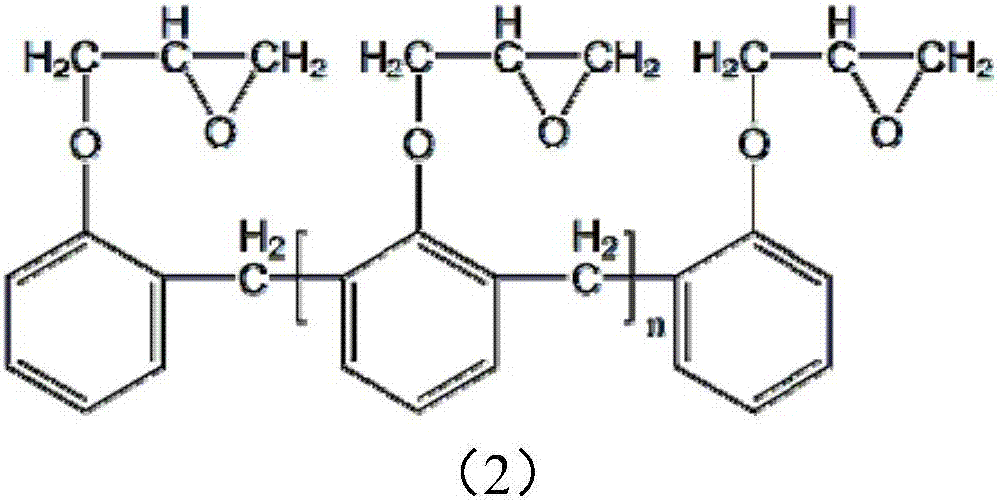

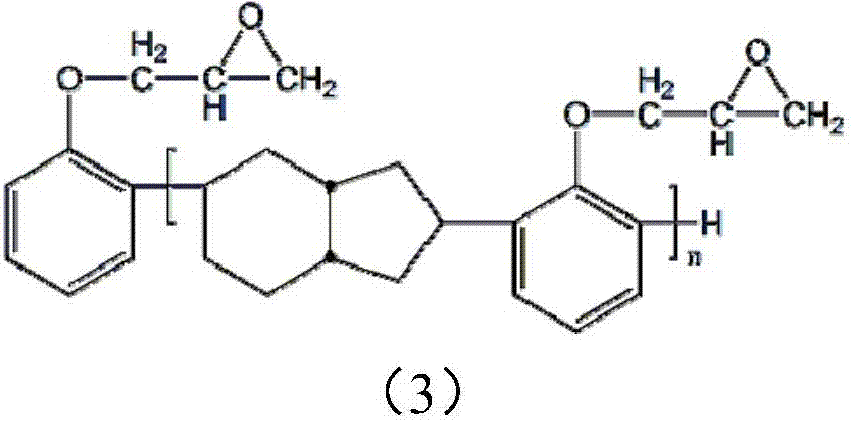

[0064] A curing agent is added to the first mixture to obtain the epoxy resin composition, wherein the epoxy resin contains a hydrogenated epoxy resin and a heat-resistant epoxy resin, and the heat-resistant epoxy resin is at least A compound having structural formula (1), (2), (3) and (4).

[0065] In the preparation process of the epoxy resin composition according to the technical solution of the present invention, firstly, the epoxy resin, the density increasing agent and the boron carbide powder are mixed and then added to the vacuum mixing tank, and then the stirring and heating programs are started after closing, and the rotation speed is set to 400~600r / min, the temperature is set to 40~60℃, within this...

Embodiment 1

[0075] Table 1 The proportion of each component of epoxy resin composition

[0076]

[0077] Step 1: Mix the epoxy resin, the density increasing agent, the flame retardant and the boron carbide powder into the vacuum mixing tank. After closing, start the stirring and heating program. The speed is set to 400-600r / min, and the temperature is set 40~60℃;

[0078] Step 2: Evacuate the vacuum mixing tank, maintain the vacuum degree at 50-100Pa, stir until there are no air bubbles, stop stirring and put it to normal pressure;

[0079] Step 3: Add the curing agent of the formula according to the epoxy equivalent, close the stirring cylinder and continue to vacuumize and stir, the speed is set to 400~600r / min, the vacuum degree is maintained at less than 100Pa, the temperature is maintained at 40~60℃, and the stirring time is 10 to 20 minutes to prepare the epoxy resin composition;

[0080] Step 4: The above epoxy resin composition is made into a neutron shielding material under ...

Embodiment 2

[0085] Table 3 The proportion of each component of the epoxy resin composition

[0086]

[0087] Step 1: Mix the epoxy resin, the density increasing agent, the flame retardant and the boron carbide powder into the vacuum mixing tank. After closing, start the stirring and heating program. The speed is set to 400-600r / min, and the temperature is set 40~60℃;

[0088] Step 2: Evacuate the vacuum mixing tank, maintain the vacuum degree at 50-100Pa, stir until there are no air bubbles, stop stirring and put it to normal pressure;

[0089] Step 3: Add the curing agent of the formula according to the epoxy equivalent, close the stirring cylinder and continue to vacuumize and stir, the speed is set to 400~600r / min, the vacuum degree is maintained at less than 100Pa, the temperature is maintained at 40~60℃, and the stirring time is 10 to 20 minutes to prepare the epoxy resin composition;

[0090] Step 4: The above epoxy resin composition is made into a neutron shielding material un...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

| Density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com