Preparation method of carbon fiber prepreg

A carbon fiber prepreg and carbon fiber technology, which is applied in the field of polymer material preparation, can solve the problems of high energy consumption and long production cycle of carbon fiber products, and achieve the effects of low energy consumption, low cost and good mechanical properties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

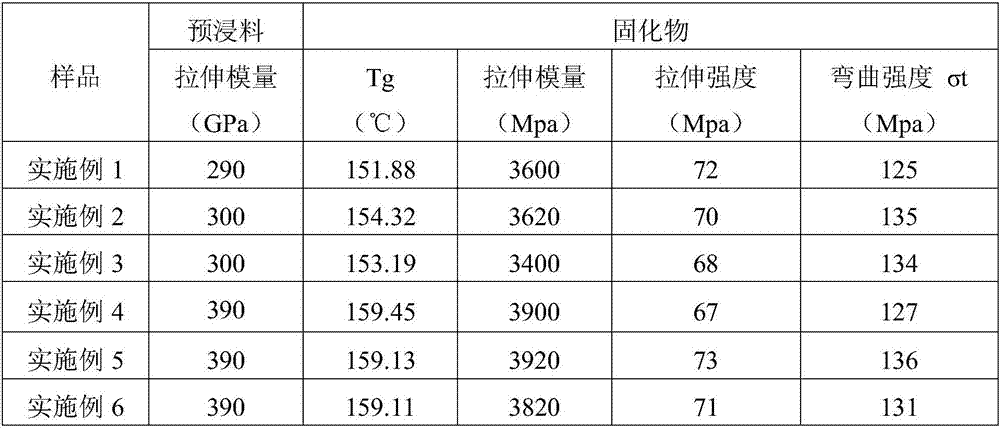

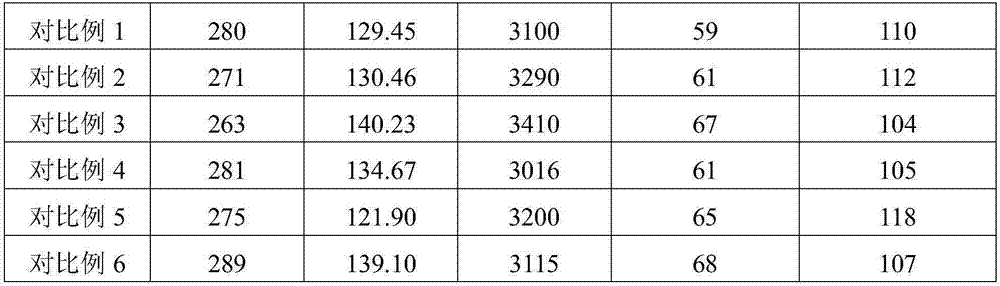

Embodiment 1

[0026] Embodiment 1: 33kg liquid bisphenol A epoxy resin E44, 37kg novolak epoxy resin NPCN-704 and 30Kg solid bisphenol A epoxy resin NPES-901 are placed in the reactor with vacuum device of 500L, at 90 Stir at ℃ for 30min, after mixing completely, get mixed solution A; add 5kg curing agent dicyandiamide 100S to mixed solution A, stir at 75℃ for 30min, after stirring evenly, get mixed solution B; add to mixed solution B 0.8kg accelerator diurea UR500, after stirring and mixing at 70°C, the mixed solution C was obtained; the cured mixed solution C was placed in the glue spreader to prepare the film used for the prepreg; the film was drawn out, And form a sandwich structure with 200kg carbon fiber 24T, pass through hot pressing rollers successively to melt the resin matrix, insert carbon fiber into the resin matrix, cool, trim, film, and roll to obtain carbon fiber prepreg, and measure the carbon fiber prepreg tensile modulus. The carbon fiber prepreg was paved and cured at 14...

Embodiment 2

[0027] Example 2: 33kg liquid bisphenol A epoxy resin E44, 37kg novolak epoxy resin AG80 and 30Kg solid bisphenol A epoxy resin E20 are placed in a 500L reactor with a vacuum device, stirred at 90°C for 30min , after mixing completely, get mixed solution A; add 3kg curing agent dicyandiamide 100SF to mixed solution A, stir at 80°C for 30min, after stirring evenly, get mixed solution B; add 5kg accelerator II to mixed solution B Urea UR300, after stirring and mixing at 70°C, a mixed solution C is obtained; the above mixed solution C is placed in a glue spreader to prepare a film for prepreg; the film is drawn out and formed into a clip with 108kg of carbon fiber M30 The core structure is sequentially passed through hot pressing rollers to melt the resin matrix, and the carbon fibers are embedded in the resin matrix. After cooling, edge trimming, film coating, and winding, carbon fiber prepregs are obtained, and the tensile modulus of carbon fiber prepregs is measured. The carbo...

Embodiment 3

[0028] Embodiment 3: 50kg liquid bisphenol A epoxy resin E44, 25kg novolak epoxy resin NPCN-704 and 25Kg solid bisphenol A epoxy resin NPES-901 are placed in the reactor with vacuum device of 500L, at 90 Stir at ℃ for 30min, after mixing completely, get mixed solution A; add 8kg curing agent dicyandiamide DDA-5 to mixed solution A, stir at 75℃ for 30min, after stirring evenly, get mixed solution B; Add 0.8kg of accelerator diurea UR200 to the mixture, stir and mix at 75°C, the obtained mixture C is placed in a glue spreader, and the film used for the prepreg is obtained; the film is drawn out and formed with 400kg of carbon fiber M40 Sandwich structure, successively passing through hot pressing rollers to melt the resin matrix, inserting carbon fibers into the resin matrix, cooling, trimming, coating, and winding to obtain carbon fiber prepregs, and measuring the tensile modulus of carbon fiber prepregs. The carbon fiber prepreg was paved and cured at 140°C for 1 hour to obtai...

PUM

| Property | Measurement | Unit |

|---|---|---|

| glass transition temperature | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com