A power control circuit for an air energy water heater

An air-energy water heater and power regulation technology, applied in the circuit field, can solve problems such as compressor safety hazards, achieve stable power, avoid compressor safety hazards, and achieve great practical value and promotion value

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

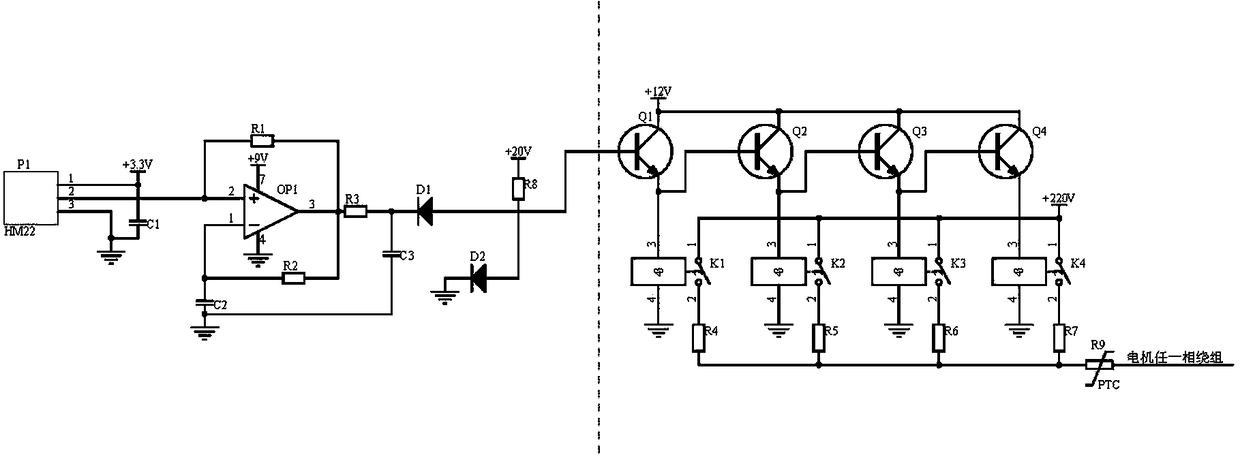

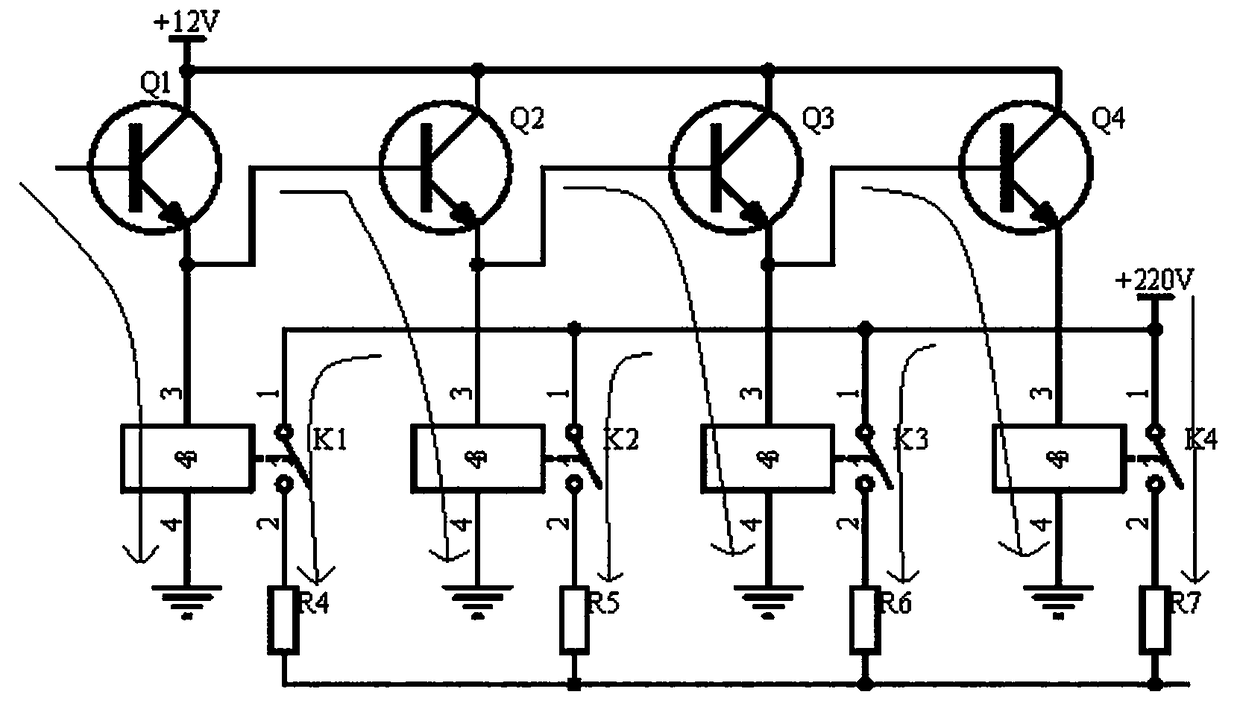

[0018] Embodiment 1, an air energy water heater power control circuit, including a pressure signal acquisition circuit and a step-by-step power control circuit, the pressure signal acquisition circuit collects the pressure signal after the air energy water heater compressor is heated and pressurized through in-phase amplification and clamping After the position is 0-20V, the pressure signal is used as the driving signal to control the conduction and cut-off of the triode of the step-by-step power regulation circuit;

[0019] The step-by-step power control circuit uses triodes Q1-Q4 to control the power on and off of relays K1-K4, the base of the triodes Q1 is connected to the positive pole of the diode D2, the common terminal of the collectors of the triodes Q1-Q4 is connected to the power supply +12V, and the triodes Q1-Q4 The emitters of Q4 are respectively connected to contacts 3 of relays K1~K4, the emitter of transistor Q1 is connected to the base of transistor Q2, the emi...

Embodiment 2

[0020] Embodiment 2. On the basis of Embodiment 1, the pressure signal acquisition circuit adopts a pressure sensor P1 of model HM22. In order to allow the pressure signal collected by the pressure sensor P1 to be used as a driving signal to control the conduction and cut-off of the triodes Q1-Q4, Firstly, the op amp OP1 is positive-phase amplified, and the positive-phase amplified pressure signal is purely an abnormal signal. In order to protect the entire circuit, diodes D1, D2 and resistor R8 are designed to clamp the potential within 0~+20V. The pressure sensor P1 The power supply terminal is connected to the power supply +3.3V and one end of the capacitor C1, the ground terminal of the pressure sensor P1 and the other end of the capacitor C1 are grounded, and the output terminal of the pressure sensor P1 is connected to the positive input terminal of the op amp OP1 and the resistor R1 One end, the inverting input terminal of the operational amplifier OP1 is connected to on...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com