Marine revolving cup atomization incinerator and incineration method thereof

A technology of rotor atomization and incinerator, applied in the direction of combustion method, incinerator, combustion type, etc., can solve the problems of high maintenance frequency, clogging of nozzles, large consumption of auxiliary fuel light diesel oil, etc., to simplify installation and connection, and reduce clogging Possibility, the effect of reducing energy consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

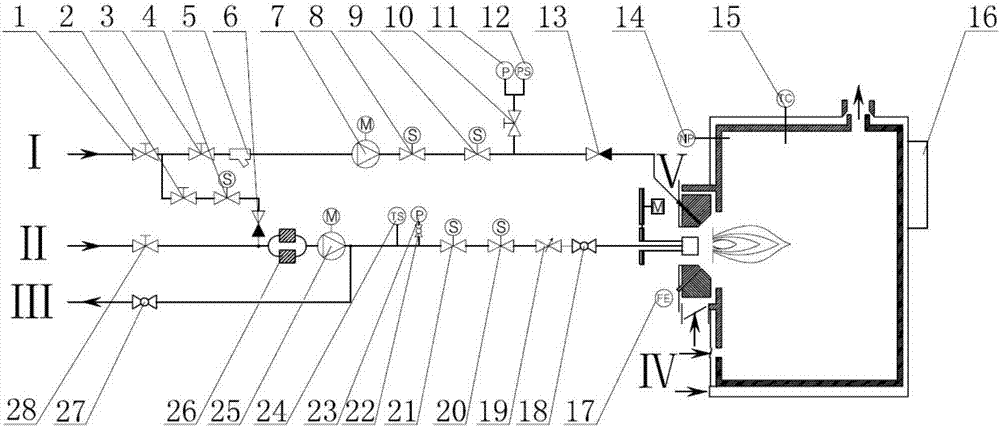

[0037] A kind of rotary cup atomization marine incinerator provided by the present embodiment, such as figure 1 As shown, it includes an ignition device I, a sludge oil inlet device II, a sludge oil return pipeline system III, an air supply device IV, a burner V and an electrical control box 16 arranged on the outer wall of the furnace.

[0038] The ignition device includes a first shut-off valve 1, a third shut-off valve 3, a Y-shaped filter 5, an oil pump 7, a first solenoid valve 8, and a second solenoid valve 9 arranged on the pipeline in sequence; The first instrument valve 10 and the first check valve 13 on the solenoid valve outlet pipeline. A first pressure gauge 11 and a pressure switch 12 are installed above the first instrument valve; the mesh size of the Y-type filter is 60 μm.

[0039] The sludge oil inlet device sequentially includes a fourth cut-off valve 28, a double filter 26, a metering pump 25, a fourth solenoid valve 21, a fifth solenoid valve 20 and a fir...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com