Combustor controlling method and combustor controlling system

A control method and burner technology, which is applied in the field of hazardous waste incineration treatment, can solve the problems of high labor intensity, difficulty in on-site adjustment, and shortened equipment life, so as to reduce material consumption, reduce labor intensity, and save operating costs. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

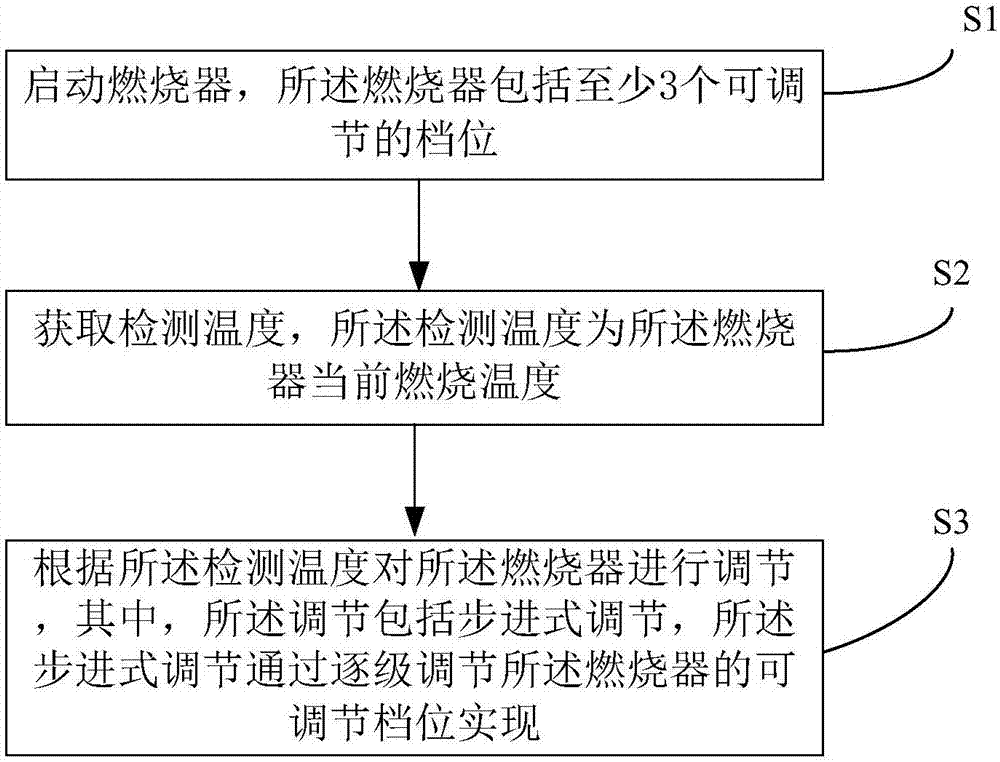

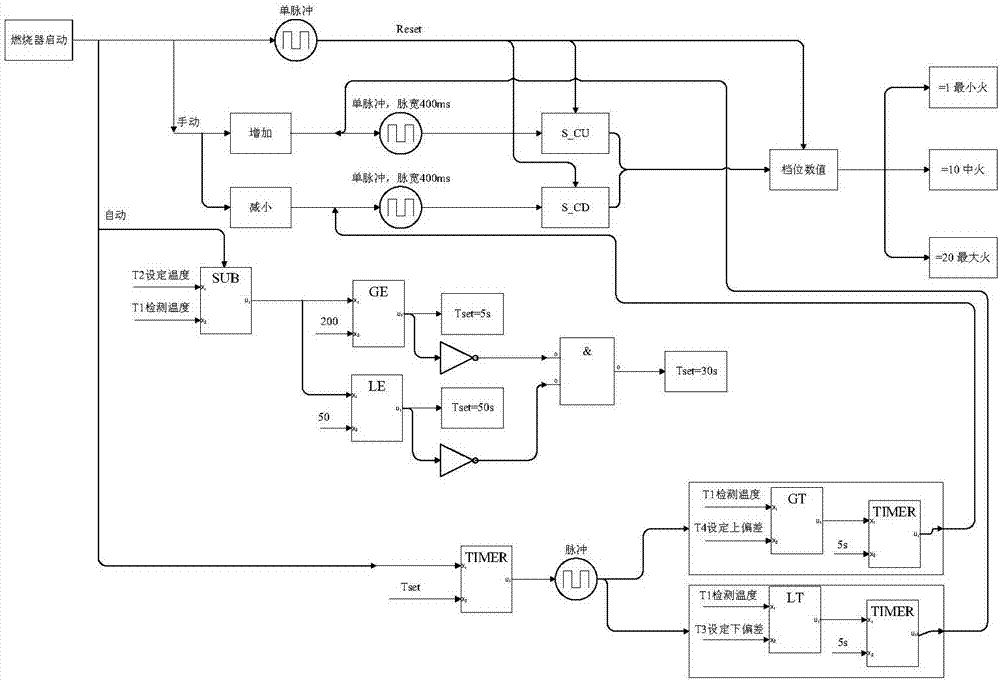

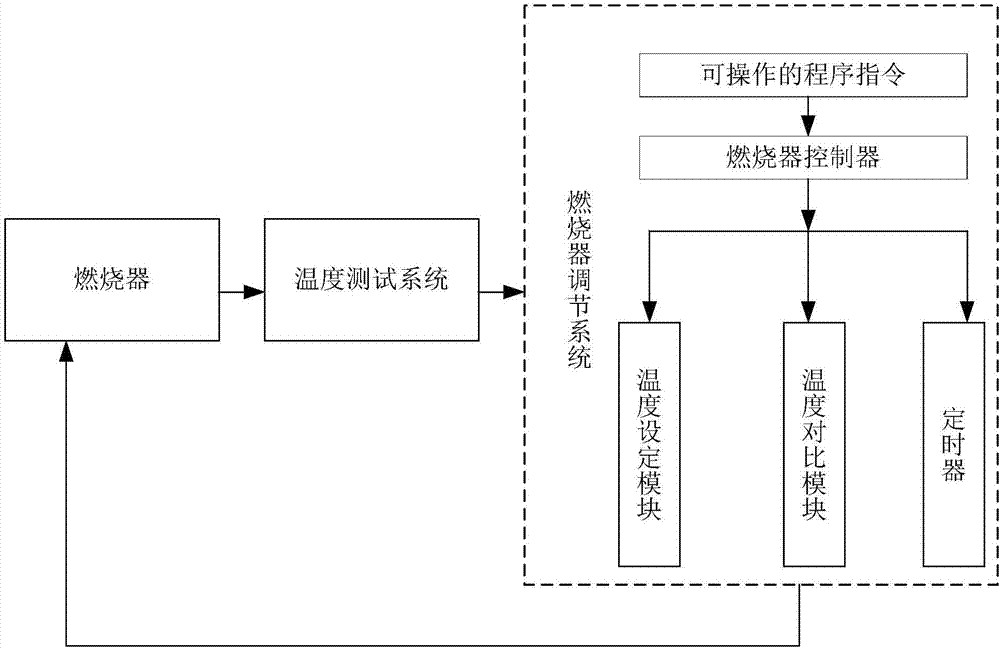

[0053] Refer below figure 1 , figure 2 and image 3 The burner control method of the present invention is schematically described, wherein figure 1 It is a schematic flowchart of a burner control method according to an embodiment of the present invention; figure 2 It is a schematic diagram of burner control in practical application according to the present invention; image 3It is a schematic diagram of a burner control system according to an embodiment of the present invention.

[0054] First, see figure 1 , execute step S1: start the burner, the burner includes at least 3 adjustable gears.

[0055] Exemplarily, the burner may be any burner including at least 3 adjustable gears. Exemplarily, the adjustable gear position of the burner can be realized by using a pulse width modulation controlled servo motor. Take a servo motor with a rated operating range of 90° and a rotation time of 12s for 90° as an example. Exemplarily, the servo motor is controlled by a pulse sig...

Embodiment 2

[0067] The present invention also provides a burner control system, see image 3 , shows a schematic diagram of a burner control system according to the present invention, the system includes: a burner, a temperature testing system and a burner adjustment system. The burner includes at least 3 adjustable gears. The burner including at least 3 adjustable gears can realize step-by-step adjustment of the burner, which can improve the load adjustment range of the burner, the utilization rate of fuel, reduce unnecessary material consumption and labor intensity, and improve The life of the equipment can save the operating cost of the enterprise and improve the efficiency. Exemplarily, the adjustable gear position of the burner can be realized by using a pulse width modulation controlled servo motor. Take a servo motor with a rated operating range of 90° and a rotation time of 12s for 90° as an example. Exemplarily, the servo motor is controlled by a pulse signal with a pulse widt...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com